Final Project Development

Project Description

We have developed an ergonomically suitable Intubation Isolation box to protect the Healthcare

providers during procedures for airborne aerosol testing. The objective of the setup is to develop a solution for intubation procedures which does not increase the Tracheal Time to Intubation (TTI) and help the professionals in cmfortable carrying out the procedures.

The project consists of 3 sections:

1. Fabrication of box model

2. Air Quality Monitor

3. CFD analysis for deciding parameters for suction.

Under current contraints, the first two sections have been completed.

Project Walkthrough

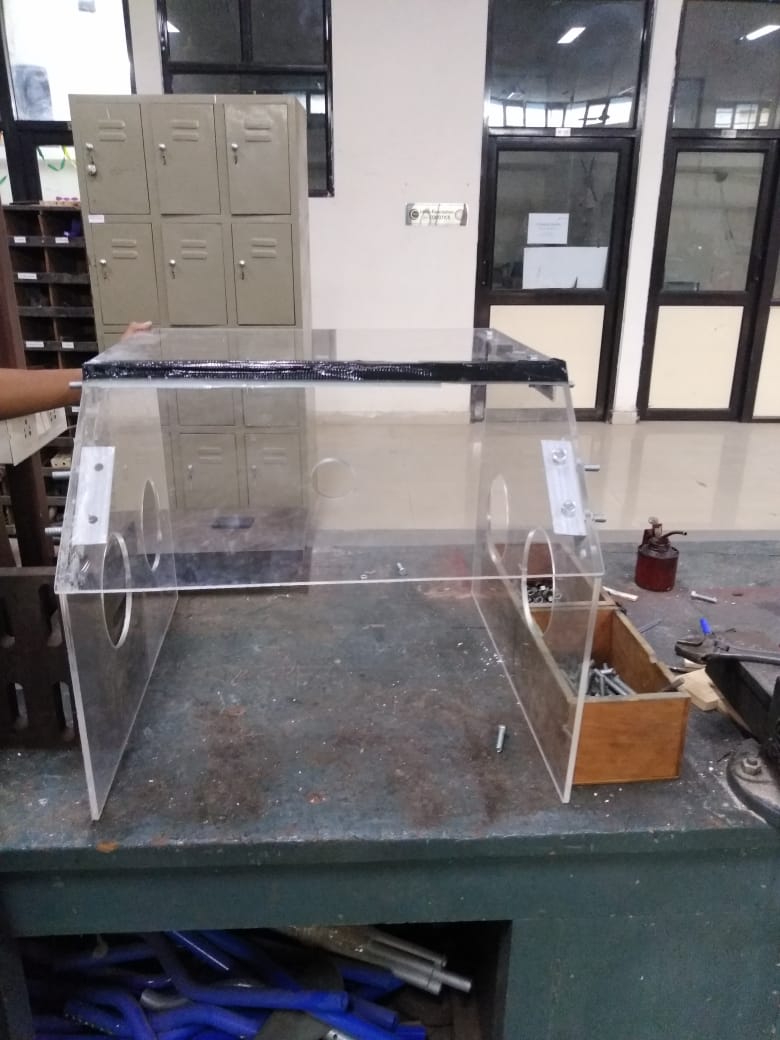

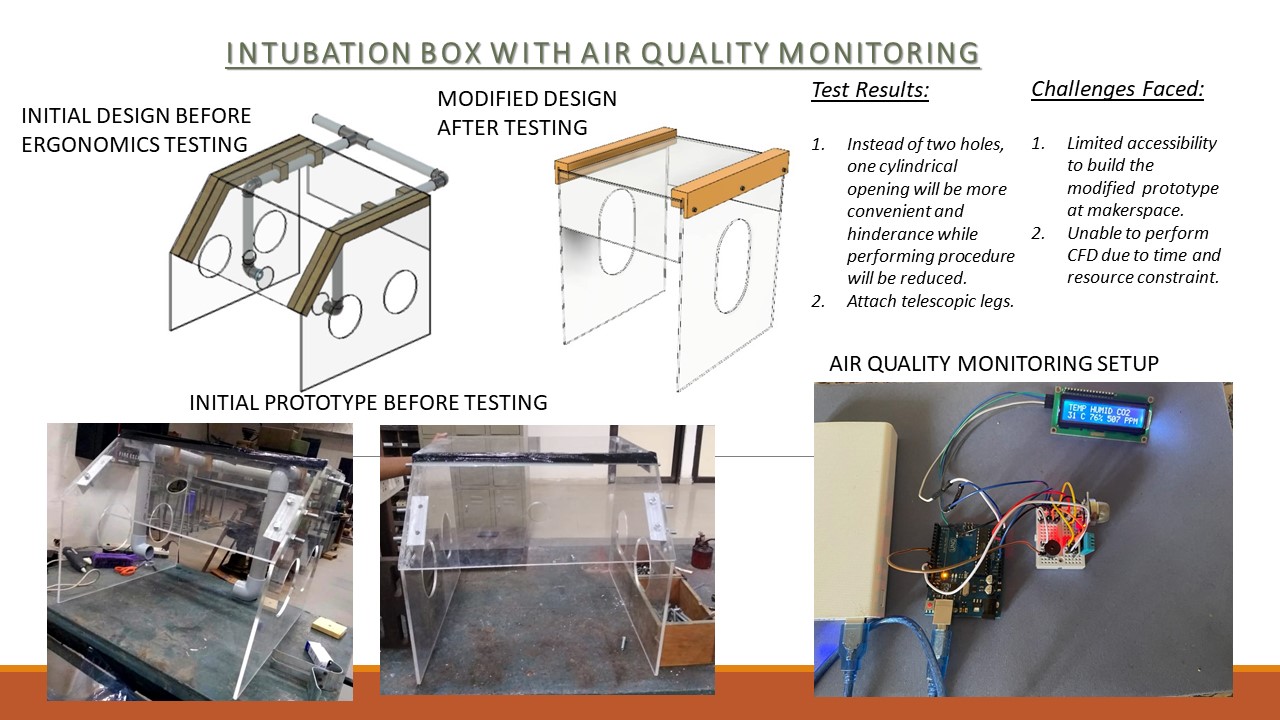

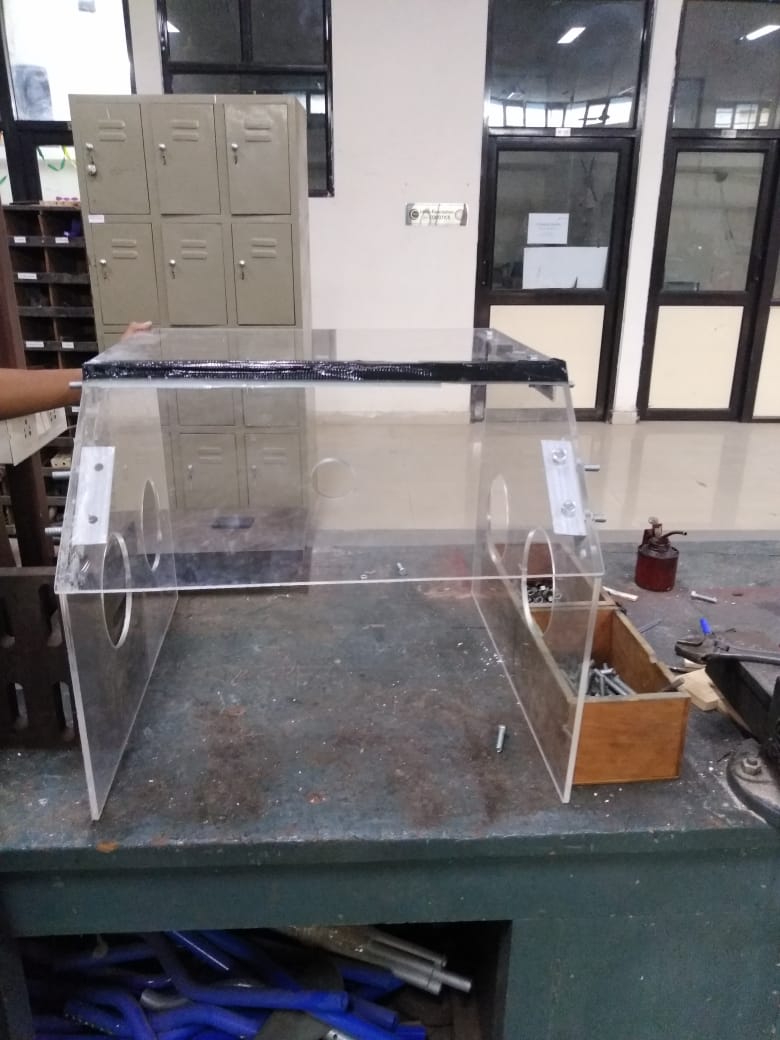

FABRICATION OF MODEL - The prototype was fabricated using press fit assemble using the Acrylic sheets. The material was selected using Cambridge material selector. The initial design incorporated two openings on each face of the model.

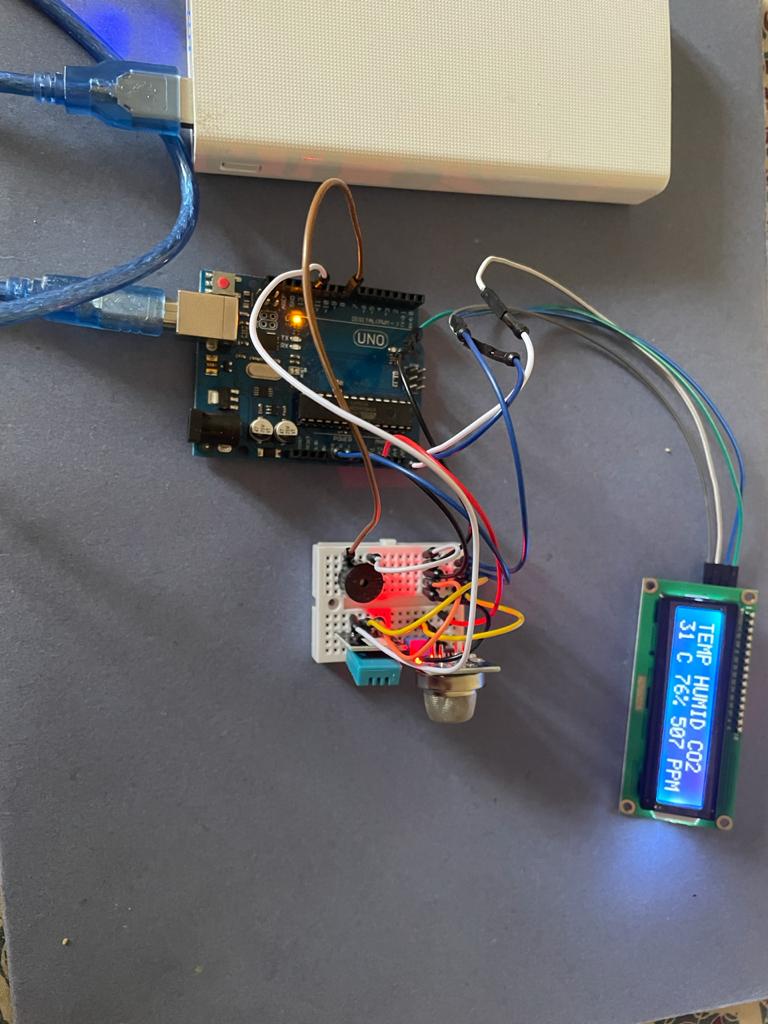

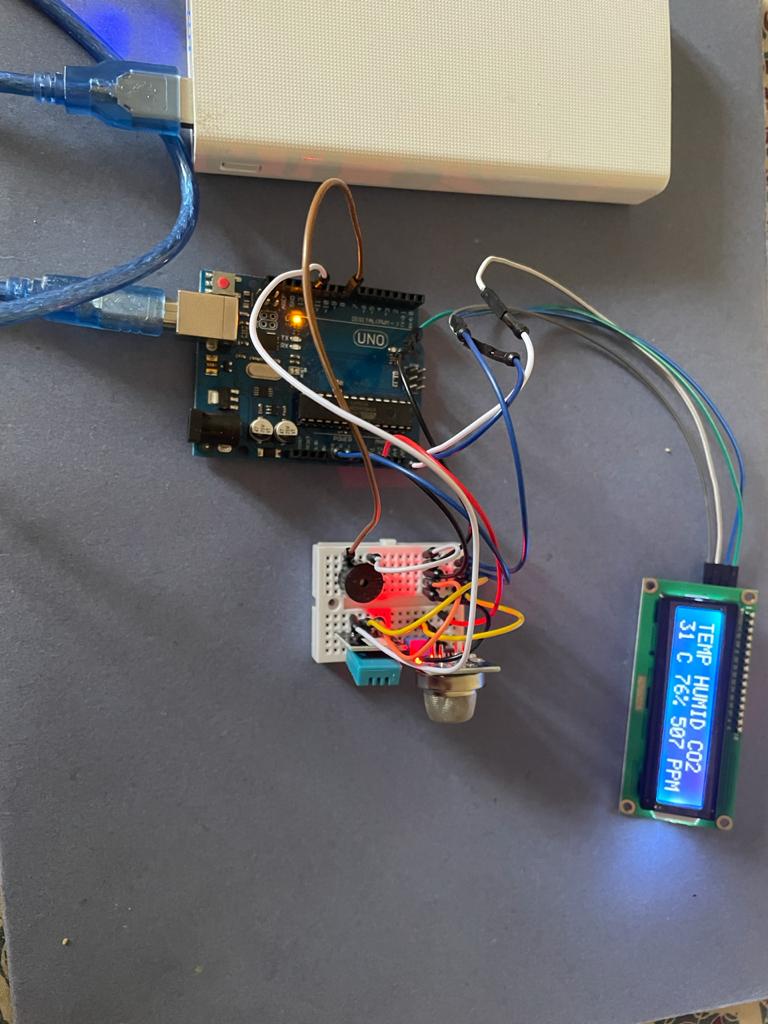

AIR QUALITY MONITOR - In order to maintain adequate air quality in terms of temperature, humidity and accumulation of carbon dioxide, I have developed a CO2 sensor using ARDUINO kit. The sensor set up consists of:

AIR QUALITY MONITOR - In order to maintain adequate air quality in terms of temperature, humidity and accumulation of carbon dioxide, I have developed a CO2 sensor using ARDUINO kit. The sensor set up consists of:

1. MQ135 gas module

2. DHT11 module

3. Jumper wires

4. LCD screen

5. Buzzer

6. Breadboard

7. Arduino UNO

ARDUINO CODE (Download) - This is the code for the Air Quality monitoring setup.

ARDUINO CODE (Download) - This is the code for the Air Quality monitoring setup.

Testing

Testing of box: The model underwent Ergonomics testimg at AIIMS with Anesthesiologist Dr. Nishkarsh Gupta. The model was tested at a hospital bed. It was concluded from the testing that:

1. Instead of two holes on each face, one cylindrical hole on each face should be there.

2. telescopoc legs could be attached so that it can be used anywhere.

Testing of air quality monitor: The MQ 135 sensor was caliberated for 24 hours before taking reading. It was then again operated for 24 hours so that we could get accurate readings. The reading obtrained through the set up were verified with sensors available in market.

Challenges faced

Limited accessibility to build the modified prototype at makerspace.

Unable to perform CFD due to time and resource constraint.