Assignment 7

3D Printing

Introduction

The 3D printing process builds a three-dimensional object from a computer-aided design (CAD) model, usually by successively adding material layer by layer, which is why it is also called additive manufacturing, unlike conventional machining, casting and forging processes, where material is removed from a stock item (subtractive manufacturing) or poured into a mold and shaped by means of dies, presses and hammers.s

Process

A 3D model is created in autodesk fusion 360 and exported using the file extension .stl which is then opened in Ideamaker software for printing.

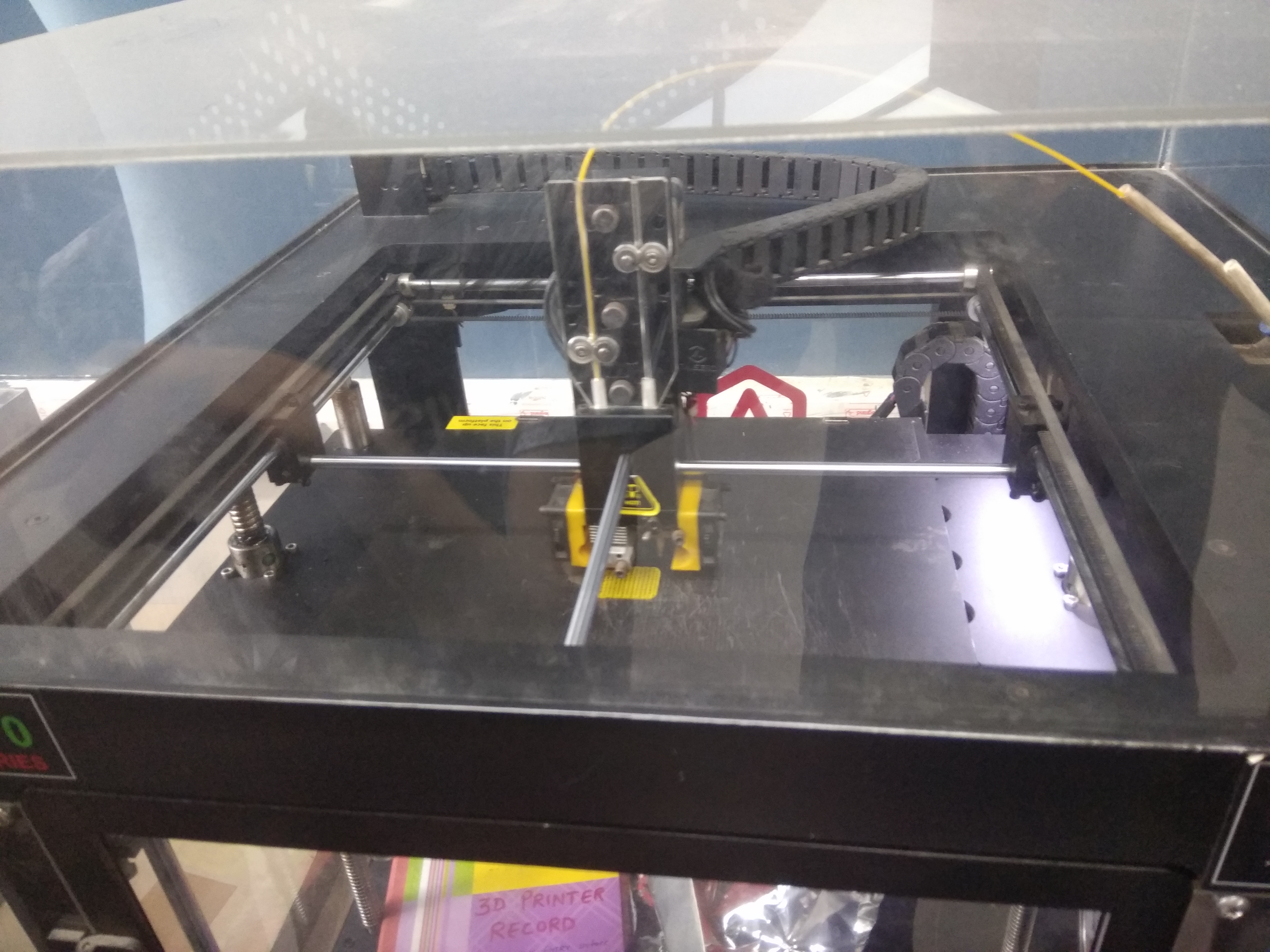

Raise 3D N2 printer is used for 3D Printing.

3D Modelling files are given below :

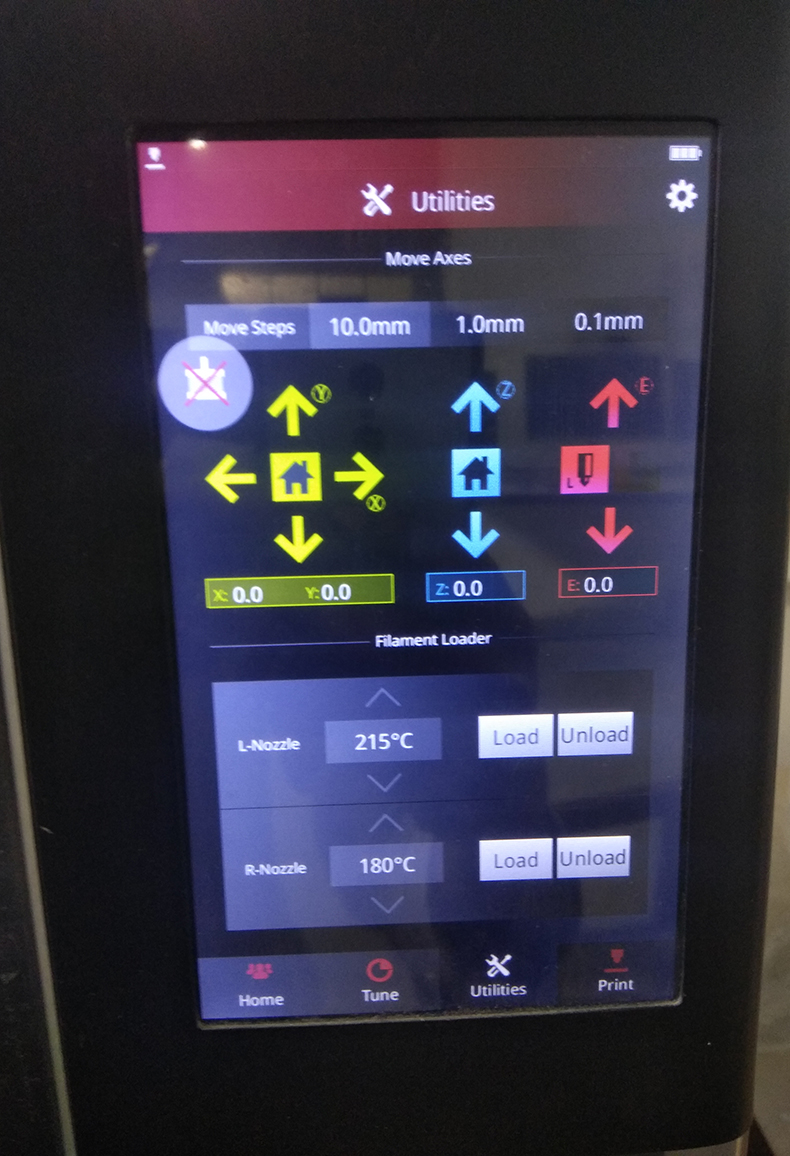

After processing in Ideamaker software, the file is copied to a pen drive and connected to the 3D printer. Shown below is the graphical user interface of the 3D printer.

Output

Video

Problems faced

1. In 3D printing, printer automatically gives autosupports to the hanging parts and a bed for the base of the object. To avoid this, the 3D model is sliced into two parts and printed seperately and joined together.

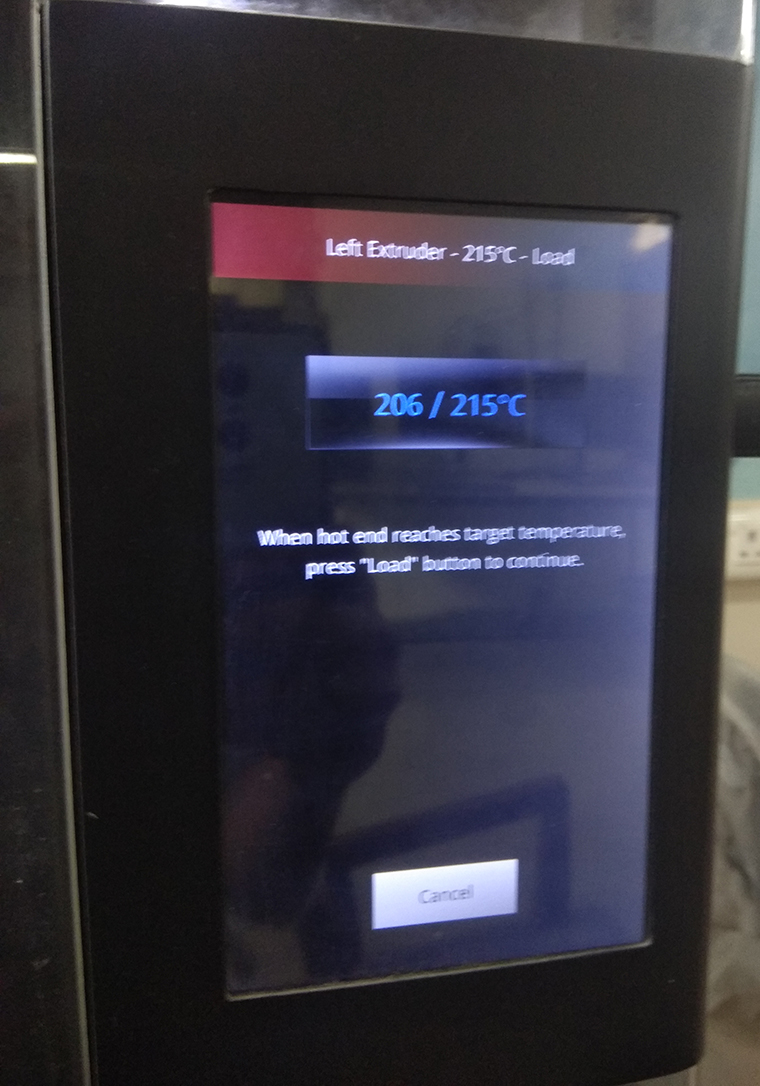

2. During the second printing process, material was not coming out of the nozzle, so unloading and loading of the material had to be done.

In 'Utilities' tab, Unload of the L-Nozzle had to be pressed, wait for the temperature to reach desired value shown, after which PLA comes out and the edge has to be cut in an angle. Then load the material.