CNC Milling (Big)

Introduction.

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product. This process is suitable for machining a wide range of materials, such as metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products. Several capabilities are offered under the umbrella of precision CNC machining services, including mechanical, chemical, electrical, and thermal processes. CNC milling is a mechanical machining process along with drilling, turning, and a variety of other machining processes, meaning that material is removed from the workpiece via mechanical means, such as the actions of the milling machine’s cutting tools. This article focuses on the CNC milling process, outlining the basics of the process, and the components and tooling of the CNC milling machine. Additionally, this article explores the various milling operations and provides alternatives to the CNC milling process.

CNC Milling Operations

- Face milling

- Plain milling

- Angular milling

- Form milling

- Straddle milling

- Gang milling

- Profile milling

- Gear cutting

- Other machining processes

NOTE:To know more about CNC milling visit Below link.

https://www.thomasnet.com/articles/custom-manufacturing-fabricating/understanding-cnc-milling/

Software Used

Software used to create cutting profile (Pocket , profile, engravings)is ASPIRE .

Procedure

Step 1:Create 2D in Aspire.

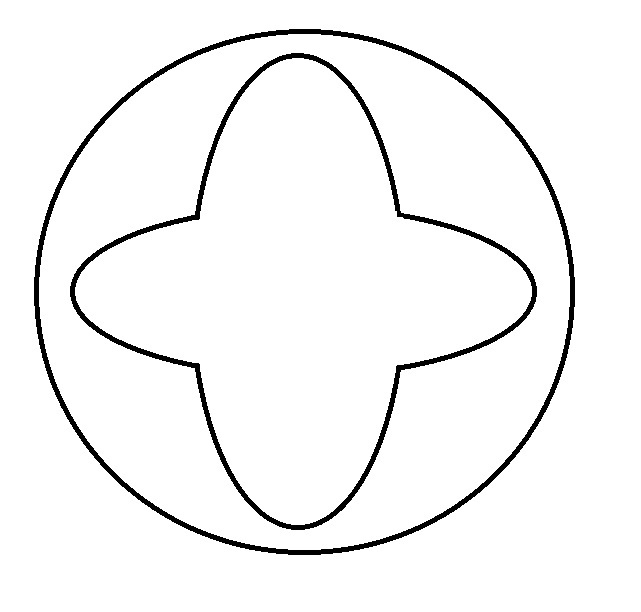

Step 2:Create profile to cut.In our case it was as shown in below Image.

Step 2:Create tool path. Goto tool path >> Select Material thickness(17mm) >> Go to Toolpath Operations (Select Pocket or Profile) >> Set Cutting Depth (0mm) and Cut Depth (17mm) >> Select Tool (6mm) >> Go to Machine Vector (Out Side for profile and for Pocket no need) >> Add Tabs (No. of tabs and size of tabs can be manipulated)>> Give name to that cut >> Calculate.

Step 3:Save as WINCNC GCode (mm) (*.tap) formate

Step 4:Feed the codes to CNC milling machine.

Step 5:Run machine.

NOTE:Do pocketing first.

NOTE:Then Profiling.

Step 6:Finished work.

-------------------------------------End of Assignment---------------------------------------