Assignment 5

Safety Practices in Makers Space.

1) Wear Safety Equipment-When cleaning up messes and using equipment, make sure you wear the proper safety equipment. Making sure you wear the proper safety equipment and checking that your safety equipment is undamaged significantly lowers your likelihood of getting injured.

2)Safety Training-Safety training is essential when working in a plant. Employees must be aware of all safety procedures, especially as they pertain to their specific position. Special training should occur periodically to reduce the risks of accidents.

3)Risk Assessment-To protect yourself and those around you, always be aware of what could go wrong and what you can do to prevent a potentially dangerous situation. Never take unnecessary risks and stay calm if you find yourself in a perilous predicament. Every company should conduct a risk assessment to identify and prevent work hazards. Some organizations choose to have a safety officer with special training to recognize and analyze hazards.

4)Maintaining Cleanliness-Keeping your work area clean does wonders when it comes to preventing accidents. A clean and organized area helps to create a better, less stressful work atmosphere. Many factors should be taken into consideration, including proper ventilation and lighting fixtures.

5)Keeping a Clear Head-Factories can pose a lot of risks, so maintaining a clear head is mandatory. Working under the influence of drugs or alcohol should be forbidden. People who must take certain medications that have side effects should notify their supervisors. Every company should ensure that its workers are aware of all safety procedures and that the work environment is safe. The rules must apply to everyone, and each breach in following them should be addressed and/or punished. No employee should ever have to worry about working in unsafe conditions, because when it comes to factory work, the consequences can be severe.

6)Follow 5S-The term 5S comes from five Japanese words.

- Seiri

- Seiton

- Seiso

- Seiketsu

- Shitsuke

In English, these words are often translated to:.

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

What Are the 5 S's?

The 5S concept might sound a little abstract at this point, but in reality it's a very practical, hands-on tool that everyone in the workplace can be a part of.5S involves assessing everything present in a space, removing what's unnecessary, organizing things logically, performing housekeeping tasks, and keeping this cycle going. Organize, clean, repeat.

To know more about 5S please visit below link.

https://www.5stoday.com/what-is-5s/Different Hand and Power Tools.

Power Tools:A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools.For Example - Hand Power Drill, Hand Saw,Scroll Saw, etc.

Hand Drill:A drill is a tool primarily used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver, depending on application, secured by a chuck.

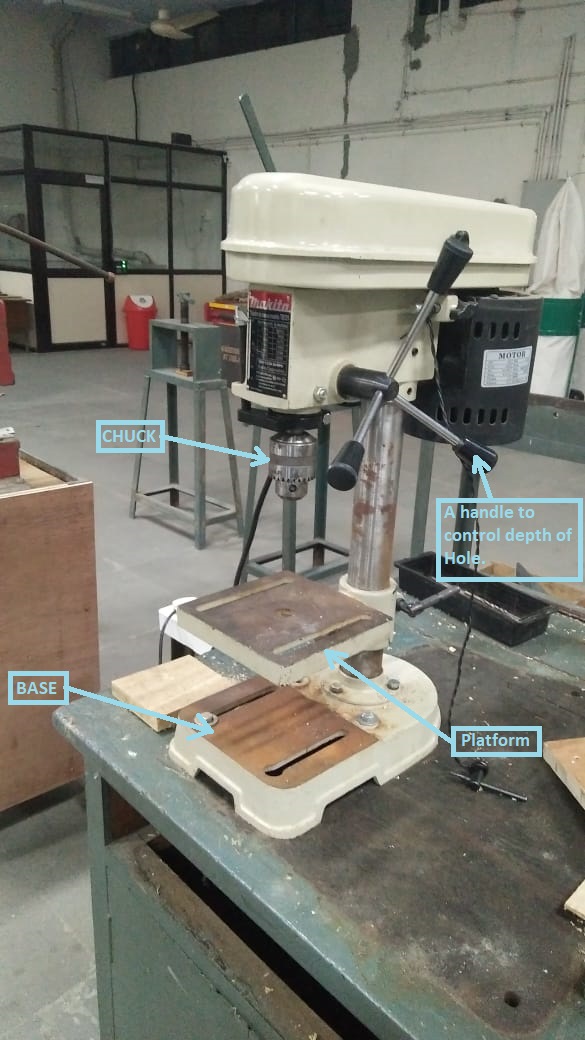

Drill Machine:Machines are relatively easy and are centered around a significant steel column; The motor, drive belt system and Chuck is connected on one hand. The second part of the column is located safely in Cast Cast Iron Base and has a two horizontal table between the two. The table can be mounted on a convenient handle-operated rack and a pumping system.

Hand power Saw:It can also be used as grinder by just changing the tool.

Scroll Saw:Scroll saws can operate with a band or a continuous or a reciprocating blade. Similar to coping saws, these powered saws are designed for intricate scroll work, spiral lines, or patterns with the added benefit of a table the material can be laid on while cutting to achieve precise rotation and detail. Creating curves with edges is what it excels at..

Compound Miter Saw:This is the miter saw on steroids. Compound saws are used to make straight, miter, and compound cuts. Instead of pivoting up and down the way a miter saws cuts, the blade is mounted on an arm that can be adjusted for complex angles, including cuts for complex scrollwork and trim. The compound miter saw is one of the best time-savers when you need to trim out windows or add crown molding.In this power tool we cal cut wood in two different angle at a time.Here we clamp component first and then cut it.

Bench Saw: It is very similar to Compound Miter Saw. In this position of rotating saw is fixed, we can clamp larger pieces of wood and move towards the saw blade to cut it.

Planar: This machine is used to reduce thickness of wooden slab.

Grinding Machine: This machine used to finish, fillet, remove burrs, chamfer.

Metal Cutting Saw: Metal saws are tools that are specifically designed to cut through metal. While there are manual tools that you can use, such as a hacksaw, cutting even one piece of angle iron using this method is tedious and requires a lot of effort. The results also leave something to be desired since, more often than not, you end up with an uneven final workpiece that requires some filing to smooth out.

Hand Tools: A hand tool is any tool that is powered by hand rather than a motor. Categories of hand tools include wrenches, pliers, cutters, files, striking tools, struck or hammered tools, screwdrivers, vises, clamps, snips, saws, etc.Some of the hand tools are explained below.

Bench Vice:A Bench vise is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever.

Files: A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.

Hammers: A hammer is a tool consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, and breaking applications.

Bending tool: Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses. The machine we have does V bending

Shearing tool: Using this machine we can shear sheet metals. Image shown below.

Practical.

Below videos shows me practicing on machines.

In below videos I am cutting Wood on Bench saw.

In below videos I am cutting Square tube using Metal cutting saw.

-------------------------------------End of Assignment---------------------------------------