Laser Cutting

Introduction.

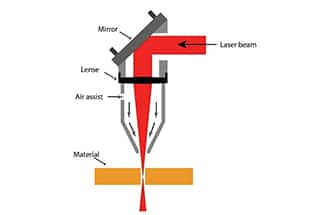

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas,leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Type of Laser Cutting

- Gas Laser Cutting (CO2 laser)

- Crystal Laser Cutting

- Fiber Laser Cutting

CO2 Laser Cutting Gas laser cutting, most often known as C02 laser cutting, is completed using a carbon dioxide mixed laser. It is made a viable by electrically stimulating said carbon dioxide mixture. When gas laser cutting was first invented in 1964, it wasn’t powerful enough to cut metals. Since then the technology has evolved, and it can cut metals too, although it is still better suited to non-metals. It has a wavelength of 10.6 micrometres, and is used in many medical and industrial settings. Gas laser cutting also uses nitrogen, which works well with metals such as steel and aluminium, although care must be taken to ensure your nitrogen is pure. Failure to do this can cause the metal that you are working with to be oxidised.

Software Used

While doing this assignment I have made 2d Model in CATIA then imported into Auto CAD and then finally imported into Corel Draw.

Procedure

I did laser cut assignmet as part of my final project

Step 1:Create 3D model in CATIA.

Step 2:Created 2D drawing of 3D model in CATIA itself

Step 3:Save as .DXF formate

Step 4:Imported .DXF file in AutoCAD to join all profile using "BPOLY" command.

NOTE:We join profile for continuous cutting of a profile.

Step 5:Imported .DXF file in Corel Draw .

Step 6:Set origin in corel draw .

Step 7:Place your drawing layout as needed .

Step 8:Select all cutting profile and change it to Hairline.

Step 9:Select all Drawing to be rastered and change it to None.

Step 10:Press Ctrl + P to print.

Step 11:Go to preferences and set Cutting speed and Cutting Power as per your material and it's thickness.

Step 12:Change operation to 'Combined' if you have to do both cutting and rastering.

Step 13:Click on 'Apply and 'Print'.

Step 14:Set focus of machine .

NOTE:Setting focus is very important for precised cutting since focus distance varies as sheet thickness changes. Please Check below video

Step 15:Go to Job and Press "GO" Button.

NOTE:Don't forget to switch "ON" machine Exaust.

NOTE:In case of emergency i.e material caut fire, You can Press emergency "STOP" button or simply 'open the lid' to shut down the operation and use fire extiguisher.

-------------------------------------End of Assignment---------------------------------------