Simply put, composites are a combination of components. They are materials made by combining two or more natural

or artificial elements (with different physical or chemical properties) that are stronger as a team than as

individual players. The component materials don’t completely blend or lose their individual identities; they combine

and contribute their most useful traits to improve the outcome or final product.

Composites are typically designed with a particular use in mind, such as added strength, efficiency or durability.

As per the assignment brief, we need to perform the task of making a composite using several materials like resin.

This assignment had to be done in a group of two and hence, I paired up with Atul Kumar who has an Architect

background.

Process:

1. Tools and Materials Used

1. Epoxy Resin

2. Hardener

3. Surgerical Gloves

4. Weighing machine (mid-sensitivity / range)

5. Flat Wooden/MDF/Metal Boards (for flattening purpose)

6. Bowl, Spatula, Plastic Wrap, Jute Cloth, and Newspapers

2. Guidelines for 20cmx20cm Composite Board

1. Cut 4 peices of jute and newspaper each (about 30cm x 30 cm). The 5 cm margin on each side is to compensate for the

loose ends left on the edges and to give extra space for laser cutting at the end of the process.

2. Wrap two large boards with plastic wrap (between which the composite is going to be compressed).

3. Mix the Epoxy Resin and the Hardner in a ratio of 2:1 (2 units of resin and 1 unit of hardner).

4. Mix the mixture till it it starts getting harder (for about 5 minutes).

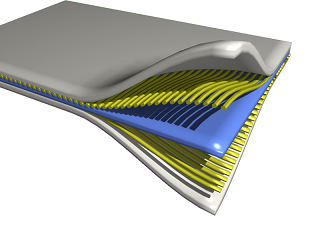

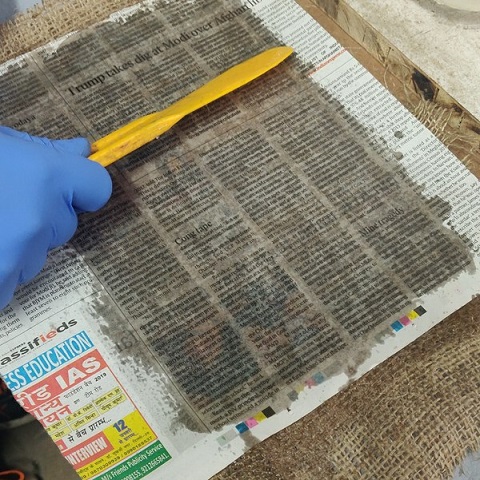

5. Place a sheet of paper and apply the mixture with scapula. Place a layer of jute cloth over the paper and apply the

mixture again. Repeat the process again and again such that the composite has alternate layers of jute cloth and paper

(soaked well in the epoxy mix).

6. Sandwich the composite between the wrapped board pieces and place it under the heavy weight.

7. Wait for about 24 hours for the epoxy to dry well. Take out the composite once dried.

8. Make the final finishing by cutting the edges by means such as laser cutting machine, sanding, etc.

You can later put some finishing layer such as paint, carbon fiber / vinyl sheet, etc. over the composite to give it a finished look.

Result:

The assignment has given me relatively good insights on Composites.

The precautions to be taken care of while undergoing the process are as follow:

1. Work carefully with chemicals.

2. Wear gloves all the time during the exercise.

3. Make sure that the weight is placed uniformally over the material while compressing.

4. Do not leave extra mixture in the bowl. Clean it once the exercise is completed.

5. Do not rub your eyes or touch any body part with your hands while working.