Laser cutting is a technology that uses a laser to cut materials. Laser cutting works by directing the output of a

high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to

direct the material or the laser beam generated. The commercial laser for cutting materials involved a motion control

system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at

the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a

high-quality surface finish.

As per the assignment brief, we need to perform the following tasks:

1. Prepare CAD Model Design Files.

2. Laser Cutting and Assembling (Press-Fitting).

This assignment had to be done in a group of two and hence, I paired up with Atul Kumar who has an Architect

background.

Process:

1. Tools and Softwares Used

1. Epilog CO2 laser cutting and engraving machine

2. Adobe Illustrator (2D CAD software)

3. Corel Draw (2D CAD software)

4. 2mm thickness MDF board

5. 2mm thickness Acrylic sheet

6. 3mm dia. Ball bearings

2. Preparation of CAD Model Design Files

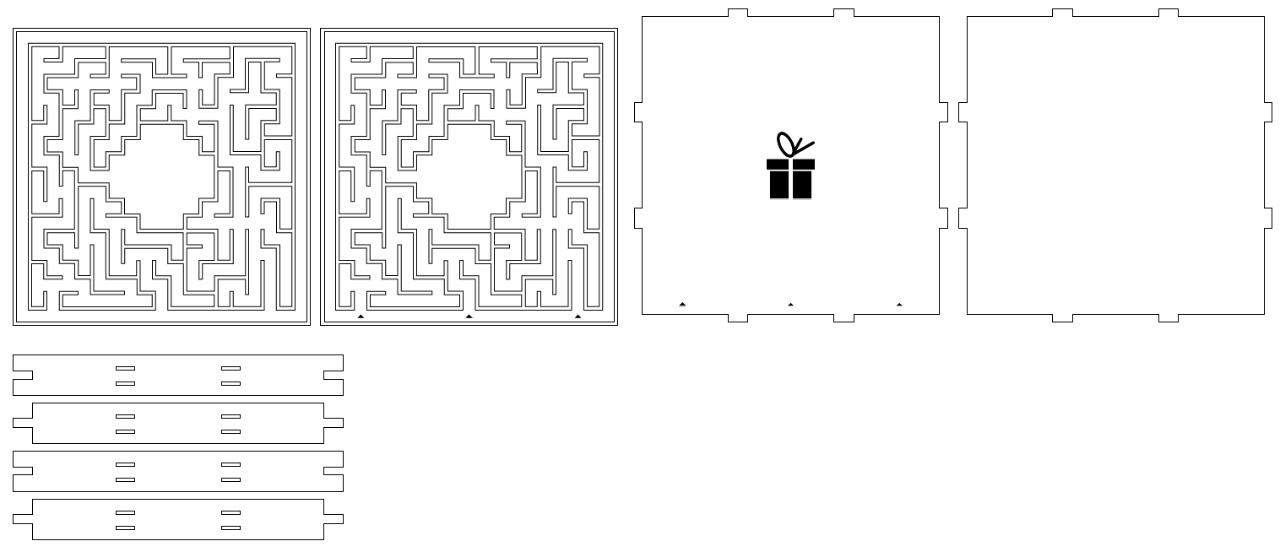

Using Adobe Illustrator, the 2D CAD file of the layout drawing was laid out.

That layout drawing has to be cut on the MDF and acrylic sheet. But while preparing the CAD file, the pressfit teeth

and grooves have to be made while taking into account the extra material that gets burnt out because of the heat. So,

for making a square of 2cm x 2cm, the actual CAD File dimensions for the square will be about 2.05cm x 2.05cm.

The final burn margin was identified as 0.15mm for the MDF and almost the same for Acrylic sheet.

For portions that are to be engraved, the illustrations were rasterized whereas the lines to be cut were kept as vector. The file was then exported as SVG and imported to the Corel Draw, where the vector lines were assigned as "Hairline" for cutting.

3. Laser Cutting and Assembling (Press-Fitting)

Press fitting is an interference fit between two parts in which one part is forced under pressure into a slightly smaller hole in the other. Press fitting method requires minimal use of glue and can be applied in construction of furnitures, parts, prototypes, and more, without the use of any screws and tools. The parts can be assembled and de-assembled easily.

The process to do the laser cutting is as follows:

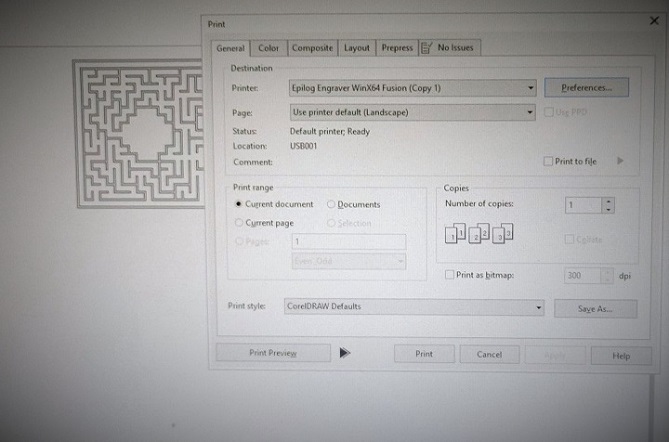

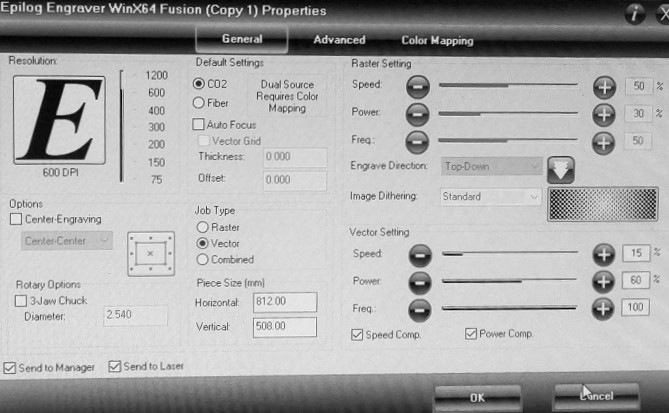

1. Open Corel Draw and import the SVG file.

2. Click "Print" in the Epilog settings.

3. Click "Preferences" and adjust settings and parameters.

3.1 Job type: Vector, Raster or combined to be selected depending on the type of your CAD file and the purpose.

3.2 Speed: The speed at which the engraver will move accross the work piece.

3.3 Power: Decides the intensity of the laser beam. More the power, more heat the beam will generate.

3.4 Frequency: It is the rate of cycle of beams. More the frequency, more the engraver head will project the beam on

the surface per unit time.

3.5 Advanced settings: It has the option to cut the work pieces as per the color code of the drawings (in RGB). Each color

can be assigned a different combination of speed, power and frequency.

4. Go to the printer. Select the job on the printer and press the 'GO' button. Before pressing the button, make sure

that the material is well placed in the laser cutting machine and the focus is set right as per the distance between

the head and the surface of the material.

5. The laser cutting machine starts performing the process.

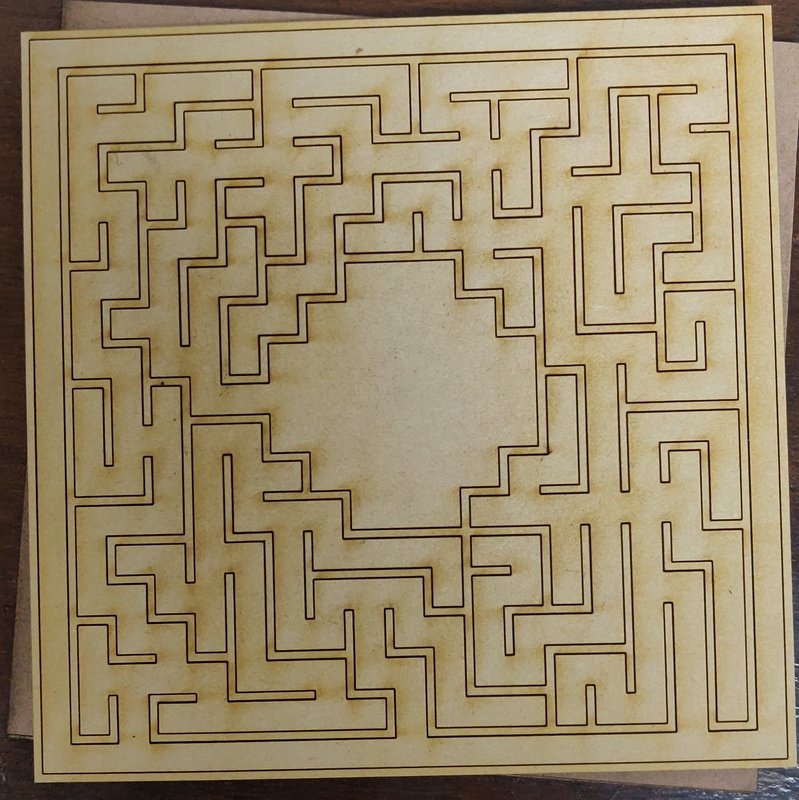

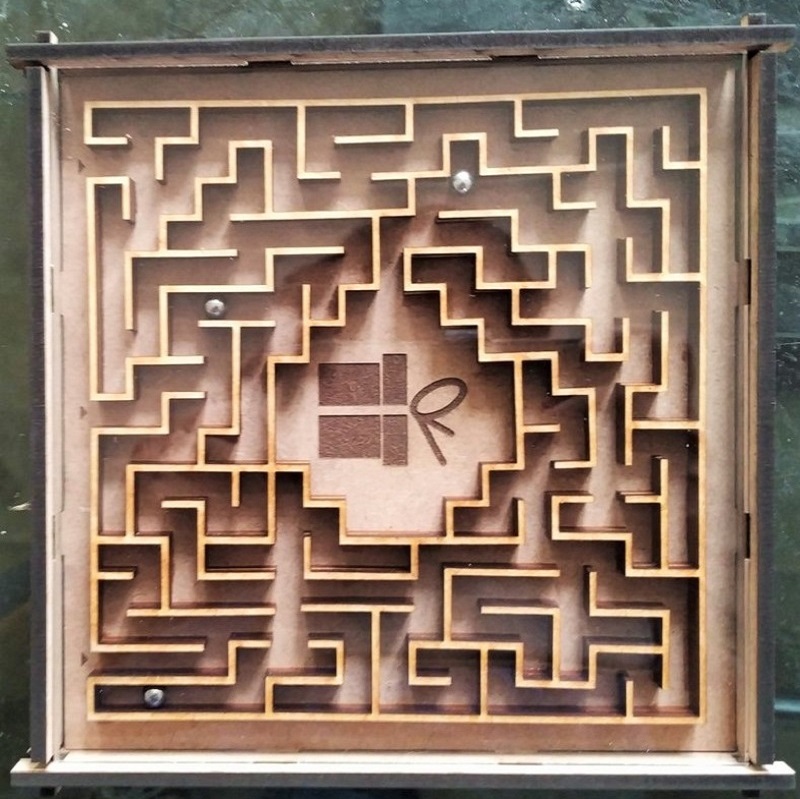

Demonstration: (The parts were press-fitted to achieve the desired results.)

Result:

The assignment has given me relatively good insights on Laser Cutting.

The precautions to be taken care of while undergoing the process are as follow:

1. Make sure that the laser beam focussing is done well for a cleaner cut.

2. Make sure that the exhause is turned on before you start the printing.

3. Make sure that while importing files to the corel draw, the scale of the drawing is same as intended. The scale of

the drawing often gets changed and need to be adjusted manually.

4. Keep a fire extinguisher handy in case a fire happens.

5. Make sure that the material is placed properly in the cutting machine and the drawing falls in the intended region

of the material.