|

Funding Agency:

RDSO, Lucknow

Investigators:

-

Dr A. Chawla

-

Dr S. Mukherjee

Other Collaborating Agencies:

Project Objective:

In earlier phases of this project we have developed FE models of the

rail and have analysed it for vertical, vertical eccentric, lateral

and for combination of the individual loading. Initially, loading

was considered to be due to only one wheel and the effect of

multiple wheels was not considered. Subsequently, in phase III of

this project we had carried out analysis for multiple wheels (axles)

on a rail. In addition, experiments had been conducted at RDSO to

validate the results of the FE models. Models for different rail and

different load combinations have been analyzed and reported earlier.

However, the analysis so far has been limited to static loading and

the likelihood of fatigue failure has not been considered so far. In

this phase of the work, we are analysing the rail for likelihood of

fatigue failures due to rail bending. In this phase, fatigue

analysis is being carried out. A local stress strain approach to

estimate the stress based fatigue life as well as chances of crack

initiation and propagation has been carried out.

Highlights of the work:

The main contributions of the current study can

be summarized as follows:

-

The current design procedure for the stress estimation in the rails

has been critically evaluated.

-

FE models have been developed for the rails. These have been

validated against the experiments suggested by us and conducted at RDSO.

-

FE models have been developed for different rail – wagon

combinations.

-

Fatigue analysis methodology has been extensively studied and a

procedure has been suggested for estimating the fatigue life of the

rails.

-

A methodology has been suggested for deciding the wheel flat limits

for safe operation.

-

An action plan for the future has been worked out to develop

a methodology for the finalization of the maximum tonnage on a rail

/ track.

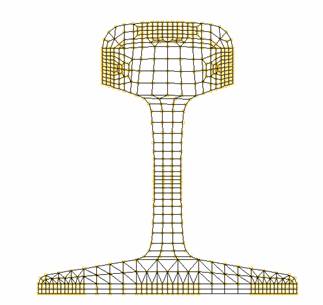

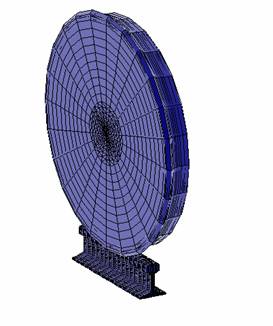

A finite element model has

to be developed carefully to obtain accurate solutions and there is

currently no procedural method for establishing a FE model. If the

geometry is known accurately, the issue is to determine the maximum

size of elements that yields sufficient accuracy. Refining the mesh

further consumes engineering time, storage space and computer run

time without any added accuracy benefits. Additional decisions have

to be made in specifying the boundary conditions and determining

material properties to be input. We have tried to establish a

methodology for ascertaining parameters relevant to FE analysis of

rails and wheels. Some typical snapshots of the FE models are

given below:

Cross

section of the FE model of the rail

|