Assignment 5

Hand and Power Tools

Our task this week was to go to Makerspace and get ourselves acquainted with the various hand and power tools. Furthermore, as part of our teaching assistantship, we are required to be well-versed with the tools so that we can train the students who would be coming to the Makerspace

What is Makerspace?

Makerspace IITD is a LEARN and Do-It-Yourself workplace for IIT Delhi community members. Users based on their interests can learn and then use various mechanical and electronics equipment. The objective here is to promote and assist new product development. Makerspace was recently added to the list of CRFs or Central Research Facilities.

What is CRF?

A Central Research Facility is of utmost importance in any academic institution where state-of-the-art analytical and high-end instruments are manned by qualified personnel to provide scientific and technical services to research students and project students. Such a facility represents a key commitment for preserving and raising the efficiency of research to the international standards.

CRF Facilities require basic training and orientation to be conducted for the users so that they use the tools and equipment carefully and responsibly.

Health and safety practices for Makerspace

- Wear eye protection glasses whenever there is risk of material cutting.

- Don’t immediately touch the workpiece just after performing operation, let it cool for a while.

- Keep all the tools and equipment at the designated place

- Clean the working area once you’re done with your work

- Wear proper footwear so as to avoid electric shocks and other accidents

- Do not let other students enter on your biometric

- Close the entry door properly once you have entered the lab

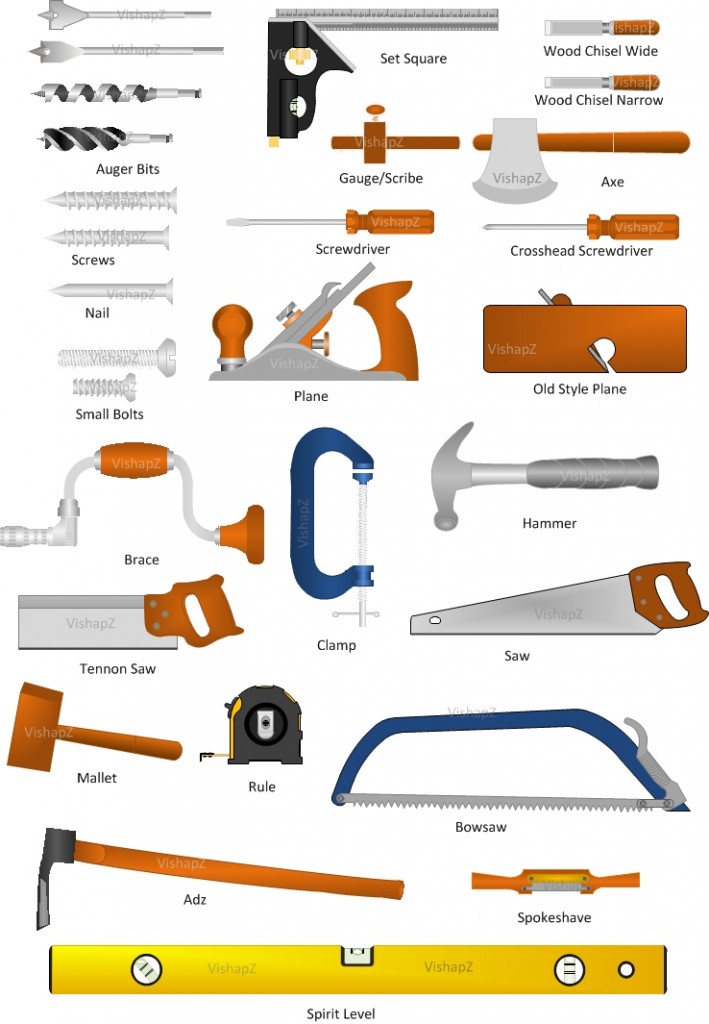

Basic hand tools

These are a few of the hand tools which we have learned in the makerspace

source: https://www.pinterest.com/pin/295056213072182810/

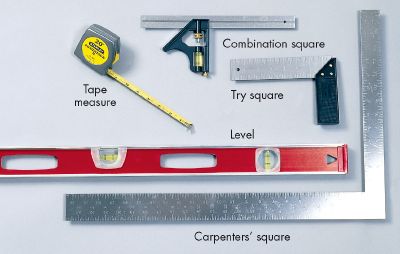

Measuring instruments for Carpentry

Source: https://home.howstuffworks.com/home-repair-tools-ga.htm

Drill Machine

- Fix the workpiece properly prior to performing any operation.

- Give enough clearances for the burrs after drilling.

- Decide the type of drilling machine recording to the size of hole required in the workpiece

- Make an indentation before you perform drilling so as to avoid slipping of drill bit over the workpiece

Hand Grinding machine

- Properly holding the machine

- Try to use machine in push mode so that if by chance machine falls on ground it will not hurt you.

- Do not touch workpiece just after the operation

- We are proper eye mask before operating

- Do a pilot run of the operation before performing the actual grinding

- Take proper care of the cutting side of the blade

- Check whether the cutting blade has been wear out if yes change it immediately

- Do not work with blunt ages of the blades

- Check for any loose connection of electrical wiring

- Hold the work priest properly using benchwises or other equipments

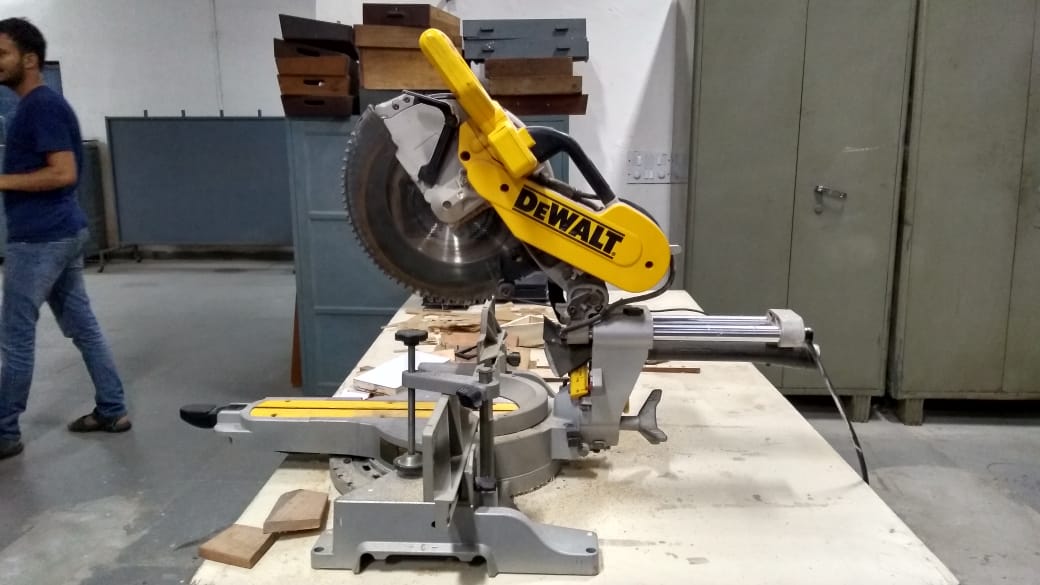

Angular cutting machine

- Measure proper angles needed on workpiece and adjust the machine accordingly

- Tight the individual levers properly

- Ensure the outlet of dust pipe goes into dustbin

- Take proper care of fingers and angles while cutting

- Wear proper mask as wood dust may go to your eyes

Bench grinder

- Hold the workpiece using proper clamping

- Take proper caution as grinding machine gives a jerk in the starting

- Give proper tolerances of grinding while designing the workpiece

Planer machine

- The linear machine is used to parallel the surfaces

- Proper allowances should be provided for the material removal during planer operation

Choosing the right tools

The selection of proper tool depends on following conditions,

- Level of surface finish required

- Size of workpiece

- Size of cutting and drilling required

- Precision of operation required

- Speed of operation required

- Type of material of workpiece