|

The creation of knowledge and its effective transfer to users is our cherished mission. We are working in

the areas of Multiphase reactors particularly Trickle-Bed Reactor,bubble/Slurry bubble column reactors,

Motionless mixers etc. In this era of globalization there is a growing awareness that environment

protection and economic development must go together.

Prof. Nigam has published more than hundred research papers in international journals. Recently, he has

published a book titled 'Three phase sparged reactors', Gordon and Breach, 1996, in association with

Prof. A. Schumpe (Germany). The high impact and significance of Prof. Nigam's work can be judged from

the extensive citations it has received in research literature, research monographs, Perry's handbook of

Chemical Engineers and textbooks. His students (graduate and undergraduate) have won various

national awards such as CSIR young scientist award, best paper award of IIChE and INAE Innovative

students Projects award (B.Tech).

He has served as a member of Scientific Advisory Committee of Ministry of Petroleum & Natural Gas,

Government of India. He is also a member of different Research Advisory Committees such as Fertilizers

Association of India, Engineers India Limited, Indian Oil Corporation Limited and Regional Research

Laboratories of CSIR. He had also served as honourable Council Member of All India Council of

Technical Education, GOI. Prof. Nigam's international reputation has brought him the various Fellowships

from prestigious international organizations such as Alexander von Humbolt Foundation, Deutscher

Akademischer Austauschdienst, British Council, French Government, Cambridge University (U.K),

University of Saskatchewan, Canada and Rensselaer Polytechnic Institute, Troy. He has large numbers of

research cooperation with prestigious foreign institutions.

Prof. Nigam is researching several promising possibilities to develop a cleaner and greener technology

for trickle bed reactors. A novel reactor configuration for the countercurrent operation of trickle bed reactor

has been proposed. The pressure drop is lower and liquid holdup is higher increasing the overall

performance of the reactor due to improved wetting of the catalyst. Trickle bed reactor mostly operates

under prewetted conditions; there is very little possibility that contact angle difference will play a role there.

The reasons for the hysteresis is that while retracting, the edges of the liquid rivulets, which flow down the

porous solid packing are held up by the pores of the packing and are not allowed to retract. While

advancing, there is no such barrier and on the contrary these pores will help in spreading. An innovative

experimental setup has been designed, which is simple and easy to fabricate called as Sliding Tackle to

Counter Pinning. This equipment can be used to measure pinning forces, which are very difficult to

measure otherwise, which will be of immense use in petroleum refining industries where porous catalyst

is the heart of the technology development.

He is very actively involved in the academia and industry interaction for the energy conservation in Fertilizer

industry. He has proposed an innovative design of heat exchanger called as 'Coiled Flow Inverter' based

on novel concept of flow inversion. The proposed innovative device has potential for the multi-functional

applications in the process industry such as, inline mixer, chemical reactors, separation process, and

cryogenic applications.

He has also introduced a new class of Static mixers 'Four Zone Axial Mixers'. These mixers intend to

homogenize feed streams subject to variations in concentration or temperature. A general design

approximates the axial mixing performance of a CSTR without need for moving parts. The residence time

distribution closely approximates an exponential distribution. The devices do very little mixing in the radial

direction and thus behave like a completely segregated stirred tank. They may be used advantageously in

series with a conventional static mixer.

Trickle Bed Reactors

http://www.scopus.com/term/analyzer.url?sid=B422AE506F04289675BD2FD314A38F20.CnvicAmOODVwpVrjSeqQ%3a520&origin=resultslist&src=s&s=KEY%28trickle+bed+reactor%29&sort=plf-f&sdt=b&sot=b&sl=24&count=1052&analyzeResults=Analyze+results&txGid=B422AE506F04289675BD2FD314A38F20.CnvicAmOODVwpVrjSeqQ%3a58

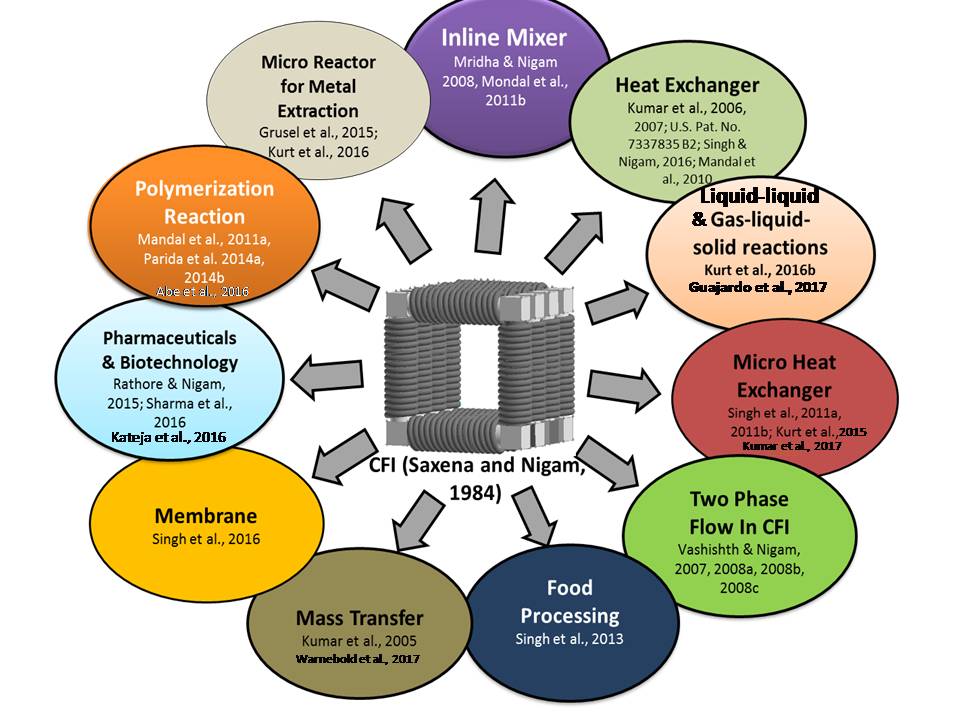

Coiled Flow Inverter:A Novel Device for Process

Intensification

Another problem industry faces is with mixing at low Reynolds

numbers; we have been looking into different inline mixers and

have developed a novel inline mixer named as “COILED FLOW

INVERTER” (CFI) whose performance is practically of Plug Flow.

This property of the device provides potential to be exploited

for many applications not only in process industry but also in

other fields. We have shown the superiority of CFI with

respect to conventional inline mixers & heat exchangers. Some

schools in Europe (ECPM Strasbourg, TU Dortmund and TU

Eindhoven) have started working on our CFI device for

polymerization & extraction processes. We are also engaged in

demystifying the physics of fluid flow in complex three

dimensional flows using CFD, RTD and other modeling&

simulation tools.

The developed CFI device at IIT Delhi has received

global attention including German company Bayer for following

applications in process industry.

Different Application Areas of CFI

Green Technology

The development of Environmental friendly Technology for the

removal of Heavy metals from Spent Catalyst obtained from

Fertilizer & Petroleum refining industries. The developed

chelation technology for metal extraction at our school have

also been now applied for recovery of metals from electronic

waste.

In order to achieve above goals considerable efforts were

placed to generate research funds and createfacilities

including the construction of a three storied building

which housed the following facilities:

(i)

Pilot plant facility to test coiled flow inverter as

heat exchanger

(ii)

Pilot plant facility for trickle bed reactor operating

upto 40 atms and 1200C

(iii)

State of art laboratory for spent catalysis (GCMS, TGA,

BET,TOC and BOM CALORIMETER)

(iv) High pressure & high temperature bubble column

reactor

(iv) Computational facilities for CFD modelling & simulation

|