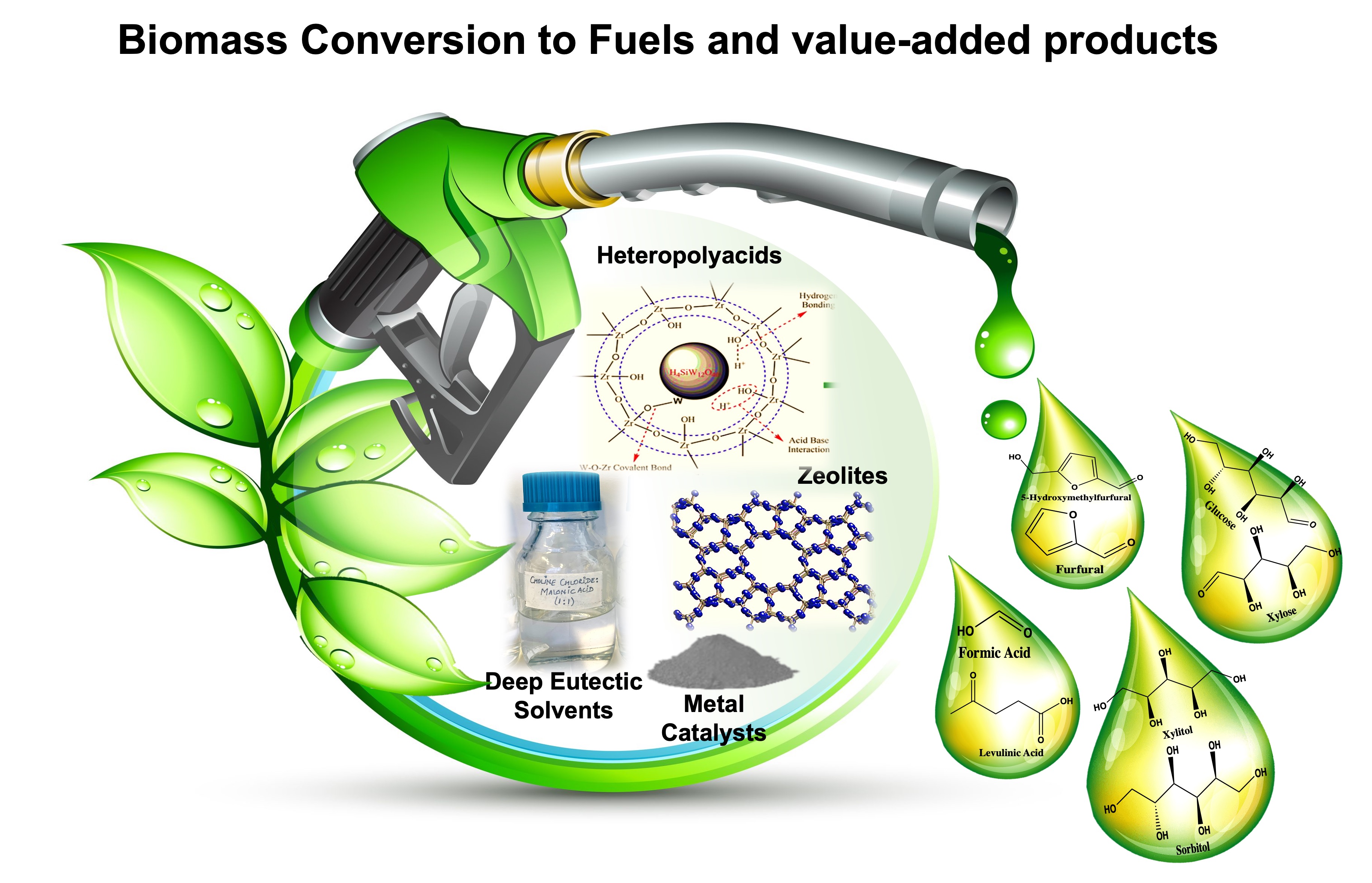

Biomass Conversion to Fuels and Value-Added Chemicals

Biomass conversion area is primarily classified into two segments in our lab i.e. (i) high temperature processing to produce fuels, we are working on pyrolysis of biomass to produce bio oil, combustible gases and catalyst grade biochar (ii) low temperature processing to produce value added chemicals, our research area includes pre-treatment, extraction of sugars and lignin followed by their catalytic conversion into building other high value chemicals. The overall theme for biomass conversion area research is to develop an integrated biorefinery with zero waste discharge to the environment.

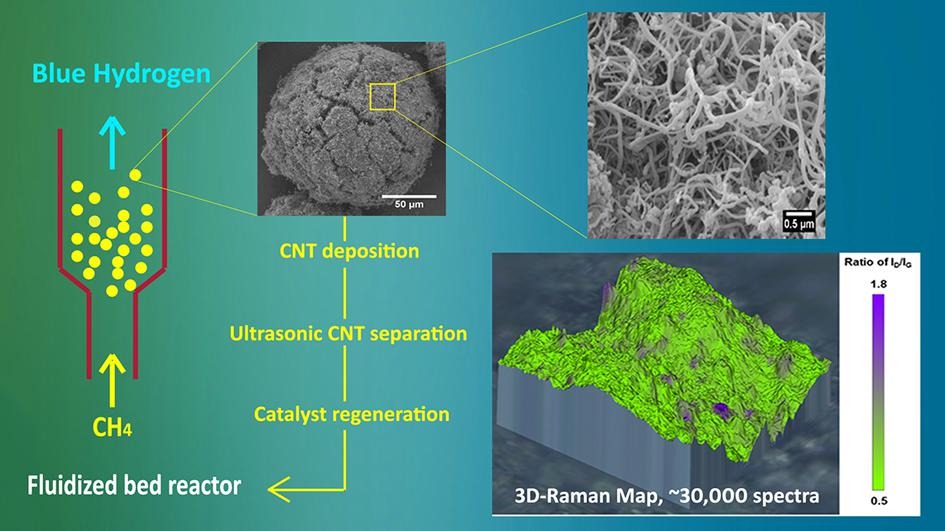

Catalytic decomposition of methane to Hydrogen and CNTs in a fluidized bed reactor

Hydrogen is used largely in refineries, fertilizer and petrochemical industries. It also is being considered as a clean carrier for the fuel cell and onboard vehicular application. Most of the hydrogen is commercially produced via steam reforming of natural gas. Catalytic decomposition of methane to pure hydrogen is an important and economical alternative to produce COx-free hydrogen and carbon nanotubes (CNTs). This research work aims at the development of suitable catalysts for the direct conversion of methane to hydrogen and CNTs. The current research involves the catalyst development for methane decomposition, CNT separation technique, application of produced CNTs.

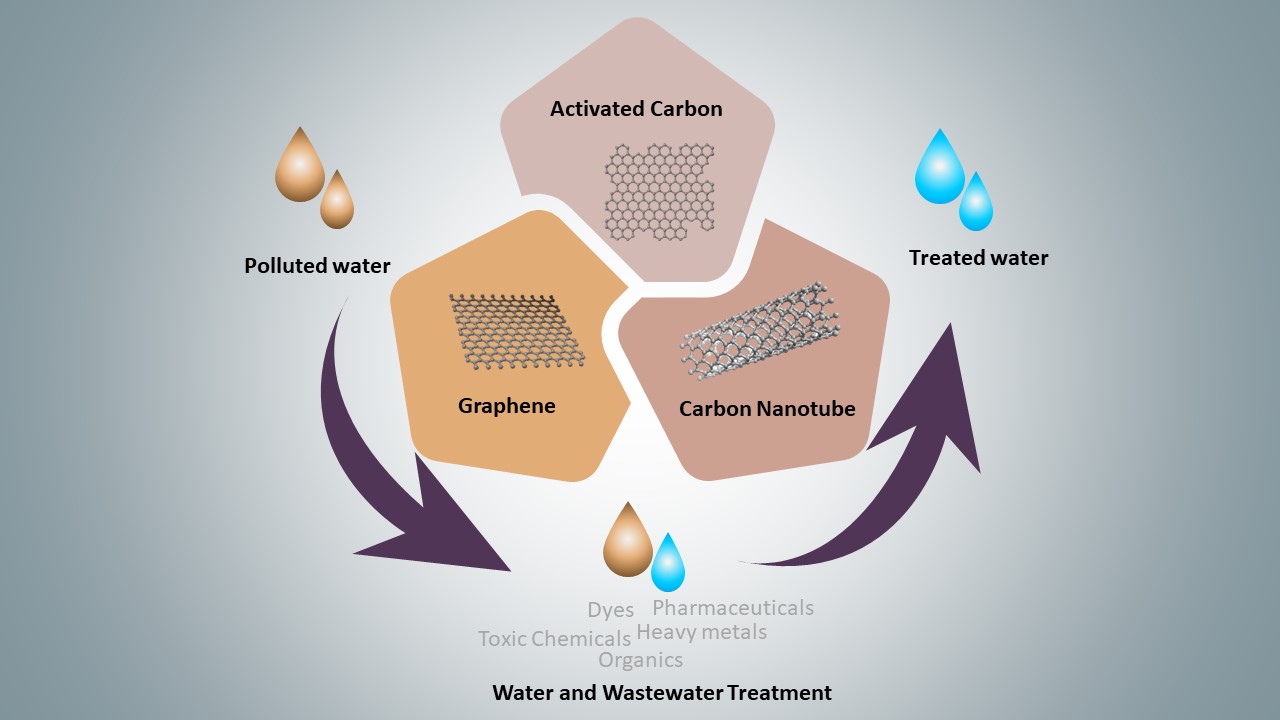

Water Treatment

The expeditious industrialization, urbanization and population boom have led to the decline in the availability of clean water. The ever-increasing demand for hygienic water has prompted the development of technologies that can be used for treating polluted water with heavy metals, microbes, and pesticides. Currently, we aim to develop novel technology for water disinfection for addressing the problem of scarcity of disinfected water. Nanotechnology has been employed to efficiently facilitate the green synthesis of silver nanoparticles and/or carbon-nanotube (CNTs) based hybrid aerogels which can be effectively used in water purification including the capacitive deionization of light metal salts, removal of organic dyes or major heavy metal pollutants like arsenic and to clean up offshore oil spills.

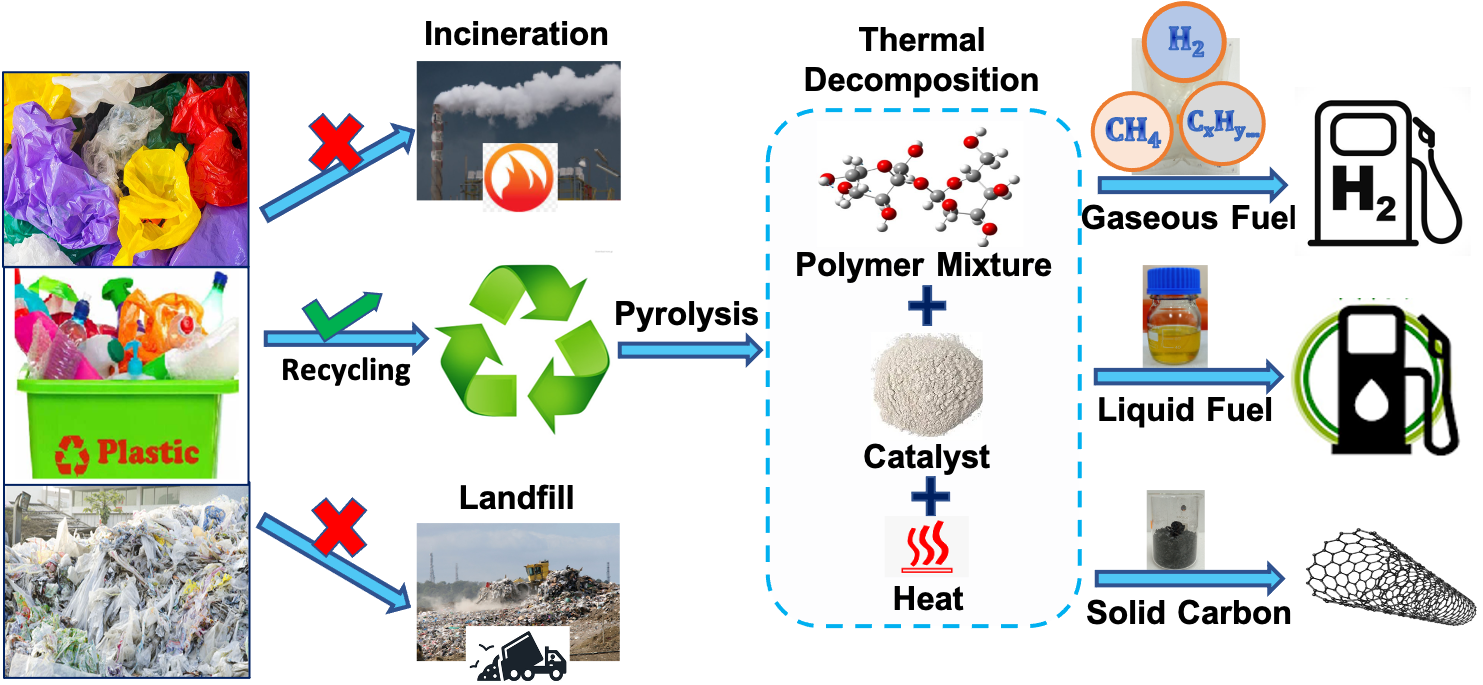

Plastic Waste to Hydrocarbon Fuel

Valorisation of postconsumer waste plastic comprising polyethylene and polypropylene is carried out at lab scale following two-step approach in a fixed bed reactor system. The two-step approach has been investigated with thermal cracking of waste plastic followed by catalytic cracking of evolved hydrocarbon gases using solid acid catalysts for the formation of fuel range liquid hydrocarbons. The recovery of aromatic compounds especially naphthenes can be a potential source of fuel range compounds rather than as a chemical feedstock.

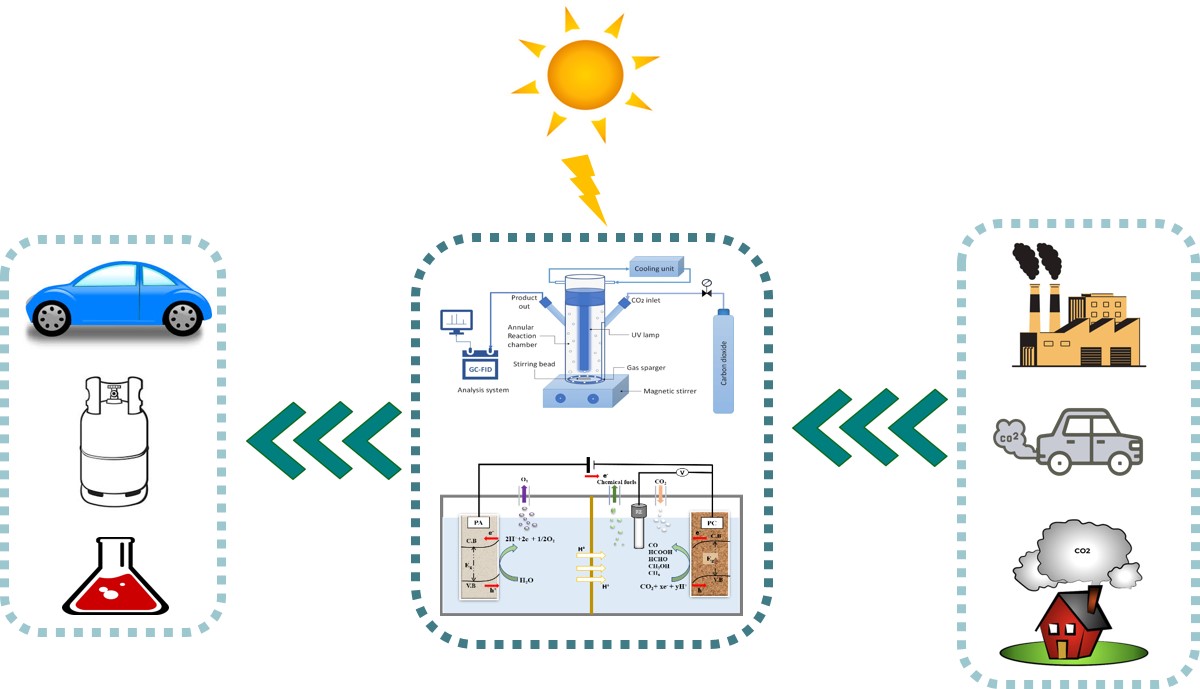

Artificial Photosynthesis for Sustainable Solutions

Carbon dioxide released through human activities such as deforestation, burning of fossil fuel, volcanic eruptions, and is responsible to climate change, ocean acidification. Recycling CO2 to produce chemicals (methanol) and fuels (syngas, methane, and methanol, methane) can eventually lead to a carbon equilibrium in the atmosphere. Artificial photosynthesis is a clean and sustainable technique to mitigate the increasing greenhouse CO2 concentrations via simultaneous energy production to meet the ever-growing energy demands. Light-assisted CO2 conversion primarily depends on catalytic materials for the prompt adsorption and conversion of CO2 to solar fuels under ambient conditions. Here in CRE Lab, we aim to inspect several aspects related to the development of new materials for efficient light-assisted CO2 conversion through photochemical and photo-electrochemical reduction pathways and unravel the conversion mechanism.

Crude to Petrochemicals

Since the emphasis on reduction of fossil fuel for transportation as well as increasing trends of per capita consumption of polymers in the developing countries, nowadays research in the petroleum refining is primarily focused on conversion of crude to chemicals. In this scenario, the conversion of di and tri aromatics of LCO to mono aromatics has a special importance. Herein CRE group, we are working in the field of developing the modified zeolite-based catalyst for achieving the conversion of di-aromatics present in the LCO fraction to mono aromatics (BTEX) without the usage of molecular H2.

Sustainable integrated systems for generating clean energy

Global warming and depleting fossil reserves are the two major issues that are to be addressed by the research community in order to keep alive the rapid growing of the global economy without overlooking the associated environmental concerns. We strongly believe that improving resource use and operation efficiency, this approach works as leverage in promoting “circular economy” and provides an opportunity to overcome the defects of each individual processes (optimization) resulting in a new highly effective and sustainable conversion process. In this regard, we highlight the importance of sustainable integrated systems, obtained by integrating technologies from different domains, to design a more powerful and effective technology to deal numerous environmental issues. Though, clean energy is the main focus in this theme, these integrated systems can serve multi-purposes.

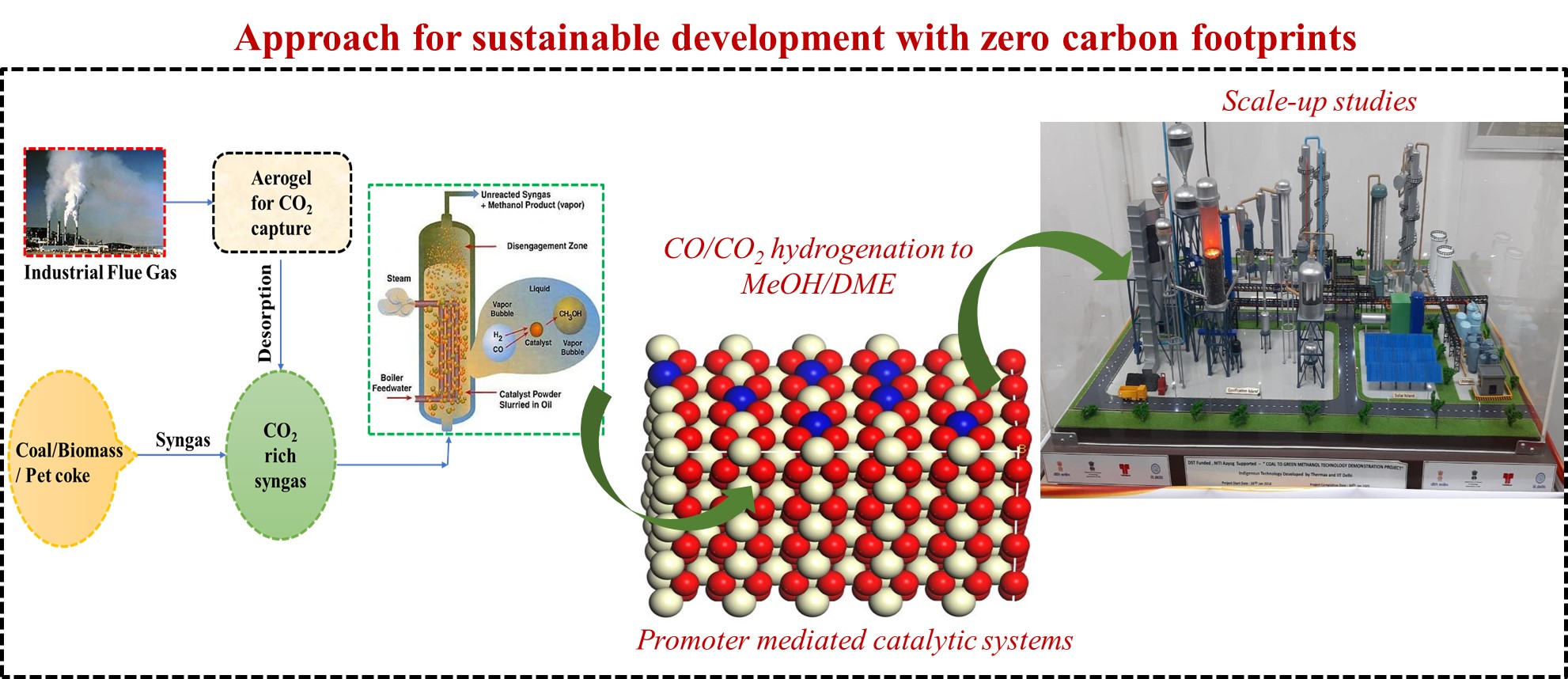

Carbon Dioxide and Syn-gas Conversion to Value Added Products

Carbon dioxide is being considered as a source of carbon for fuels and chemicals production. This idea could be a promising strategy for countering global warming and climate change. We have also been working on the thermo-catalytic process for CO2 and developed a novel highly active and stable catalyst for dry reforming of methane. Currently, we aim towards utilization and conversion of industrial flue gas via tri-reforming of methane process and conversion of syn-gas, CO2 rich syn-gas conversion to several valuable chemicals. We are focusing on the development of several novel materials for the conversion of syn-gas, CO2 and CO2 rich syn-gas conversion to methanol in fixed bed and slurry bed reactors.

Catalytic non-oxidative methane upgradation into liquid aromatic hydrocarbons

Global necessity for petroleum crude is continuously increasing due to high dependency on oil, gas and various other petroleum products. Natural gas (methane) is as an alternative to petroleum for the production of chemicals and other clean liquid fuels. Direct non-oxidative methane conversion into aromatic hydrocarbons is an excellent approach to exploit the natural gas. Zeolite supported 3d and 4d transition metal catalysts are used for direct methane conversion into aromatic compounds with high selectivity and conversion.

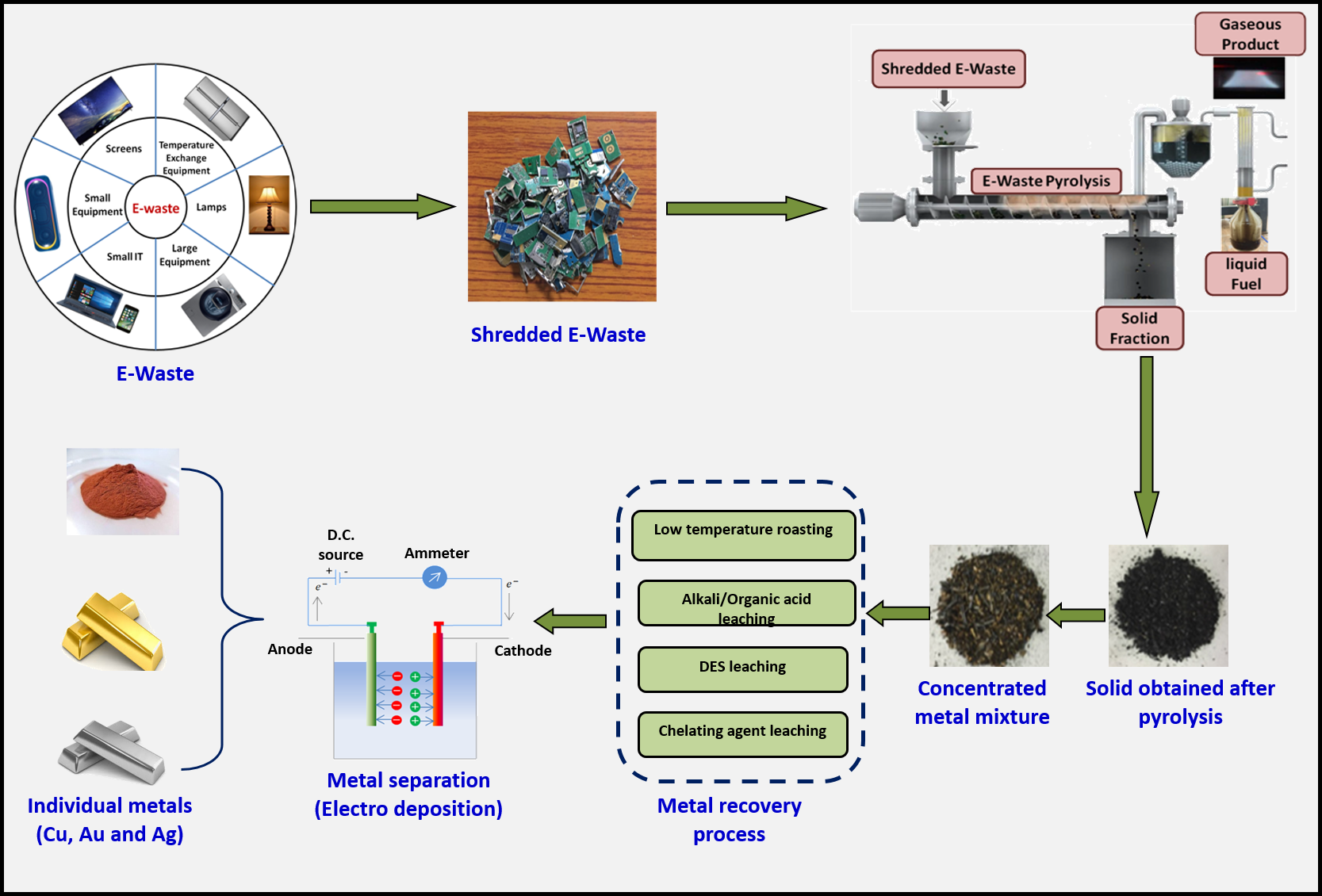

Extraction of Precious Metals from E-waste Using Green Technology

We are also targeting E-waste, which is the fastest growing waste stream with an annual growth rate of 3-5%, containing various toxic substances and therefore unregulated accumulation may lead to a serious threat to human health and the environment. Metals and plastic are the major components of e- waste with a share of 61% and 21% respectively. Therefore, we aim to develop sustainable technology for e-waste management by conversion of e-waste plastic into valuable product followed by the separation of different metals for further reuse. The individual metals will be recovered from the separated metal fraction using the green approach.