Research Focus

On the one hand world’s manufacturing systems are striving themselves to become “smart factories” which are intelligent enough to synchronize physical operations and information technology as part of the fourth industrial revolution or Industry 4.0. On the other hand, emission norms of industrial processes are continuously getting stringent to reduce the carbon foot prints, forcing the process industries to operate more efficiently without moving away operating region where the profit is high. According to a study by PWC, India, one of the key components of industry 4.0 is smart automation and data exchange in manufacturing technologies through advanced data analytics. Hence in future, Advanced Process Control (APC) strategies, which are smart, play a pivotal role to achieve higher process efficiency and safety by operating the process by satisfying operational constraints.

Our research group is primarily working on “smart or intelligent APC strategies” with applications to process industries.

Our group also work in the area of Machine learning based modeling and inference of Atmospheric Phenomena and material properties.

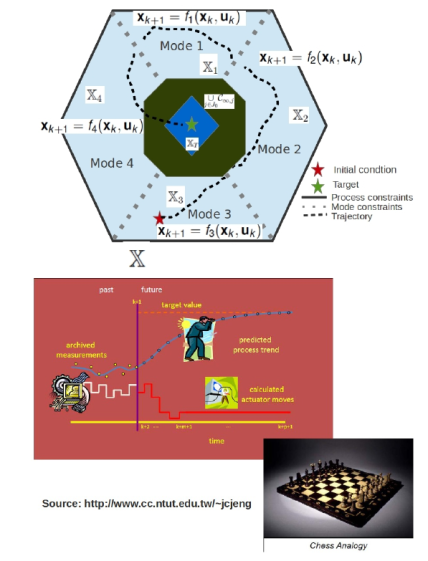

Model Predictive Control

(Collaborator: Prof. Sharad Bhartiya, IIT Bombay)

Model Predictive Control (MPC) is an optimization based advanced control strategy for dynamical systems. All classes of the MPC algorithms utilize an explicit, dynamic process model of the plant to predict the future response and optimize a desired objective over a future horizon, incorporating operational constraints to obtain an optimal profile of manipulated inputs.

We are specially interested in MPC of Switched Systems, where continuous and discrete process variables are involved, MPC of batch process, MPC solutions with novel learning algorithms, such as reinforcement learning, Explicit MPC, where optimization problem is pre-solved using multi-parametric programming, and Stochastic MPC, where process constraints are interpreted probabilistic fashion, allowing for a small violation probability.

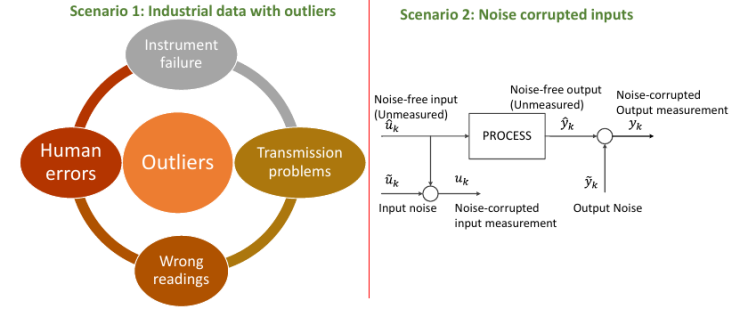

Data driven process modeling

Process models for APC could be generated by (i) first principles using physical knowledge of the process such as mass and momentum balances; (ii) completely data driven black-box models; (iii) grey-box models which are a combination of both the formers. In reality, it is acutely difficult to synthesize first principles models of industrial units due to their complexity. Moreover, its validity remain questionable if there are a number of assumptions used while modelling for the sake of simplicity. Hence, the data driven system identification techniques are proven to be feasible alternatives in this situation.

Sometimes the routine operating data tend have outlying measurements or “outliers” due to instrument failures, wrong instrument readings, potential human errors, and transmission problems. Use of operational data containing outliers could lead to poor fitting of the model parameters.. In this connection, we are interested in developing robust methods to mitigate such scenarios.

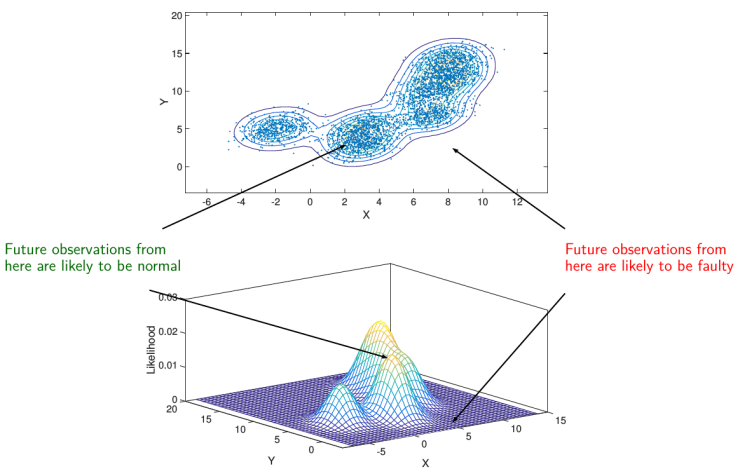

Fault detection and diagnosis of process systems

(Collaborator: Prof. Sandeep Kumar, Department of Electrical Engineering, IIT DELHI)

Process system monitoring is of paramount importance to ensure safe operation. It includes the monitoring of instrument, controller, equipment and process. Monitoring involves timely and reliable detection of fault, diagnosis of its cause and carrying out corrective actions that bring the system back to the normal conditions. Fault includes performance degradation, failure or any abnormal event that has economic, safety and environmental impact. In the recent times industries started automating process monitoring approaches using data based multivariate statistical approaches due to availability of large amount of historical process data.

Our current research interests are on fault detection and isolation of chemical process (i) with multi-modal characteristics, (ii) nonlinear characteristics, (iii) early detection of abnormal scenarios in the process operation. We also are keen on identifying and representing causal relationships between various process variables that encode process dependency and connectivity. Our solution approaches are mainly based on probabilistic latent variable models and Bayesian inference.

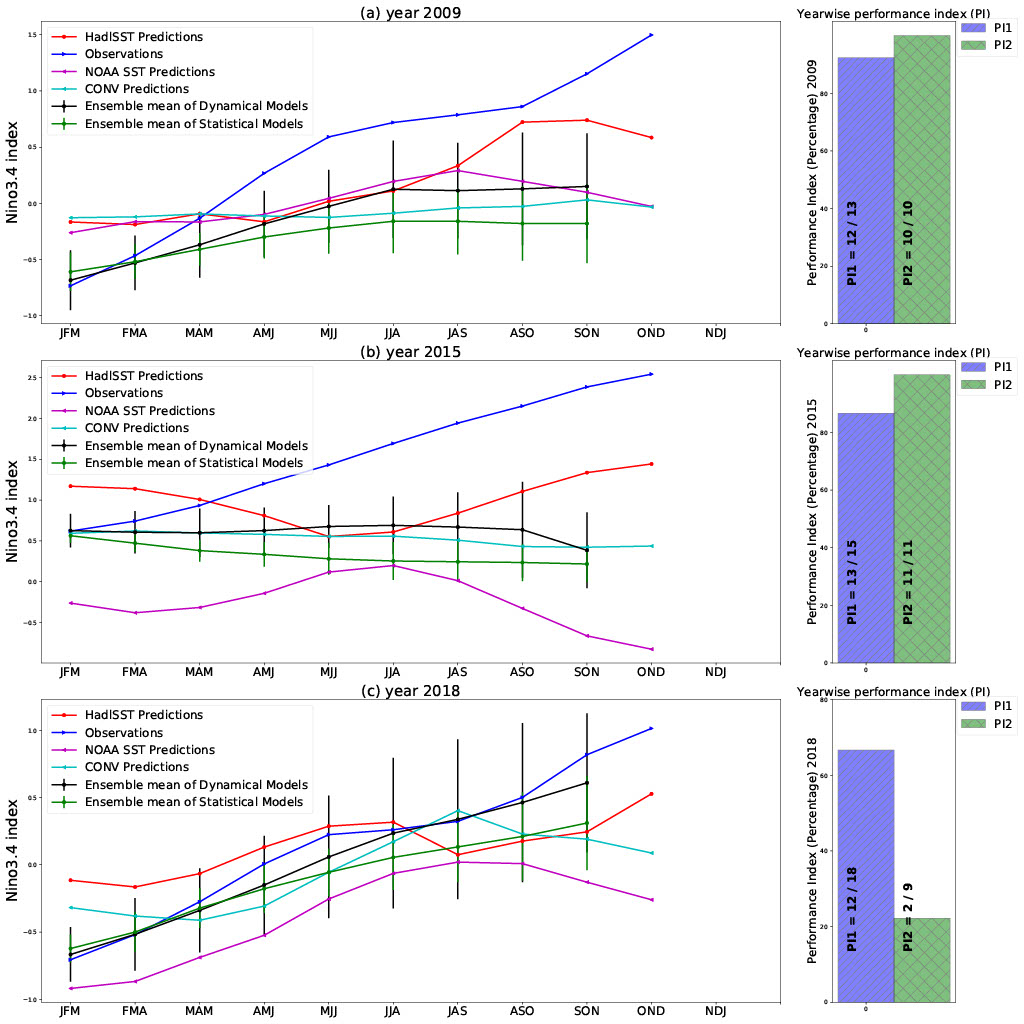

Machine Learning based prediction and inference of Atmospheric Phenomena

(Collaborator: Prof. Sandeep Sukumaran, Center for Atmospheric Sciences Sciences, IIT DELHI)

As Indian economy is highly dependent on summer monsoon rainfall its accurate and reliable prediction is an indispensable task. A traditional approach to achieve this is by means of GCM simulations. Considering the fact that India is undergoing un predicted and unprecedented cycles of floods and draughts, it is high time look at these predictions from a different angle. In this proposal we propose an alternative approach to deal with this problem by historical data mining. We propose to mine historical data sets of last 25 years that anticipated to have the latent signature of these events. The tools would be advanced machine learning algorithms such as deep LSTM network and its variants. As such we are planning to address the following key objectives: (i) modelling of India summer monsoon rainfall by deep dynamic recurrent neural network such as LSTM and its variants, (ii) Use a hybrid approach to fuse the output from ML based models and outputs from GCM to get spatially distributed prediction, by employing suitable statistical approaches.

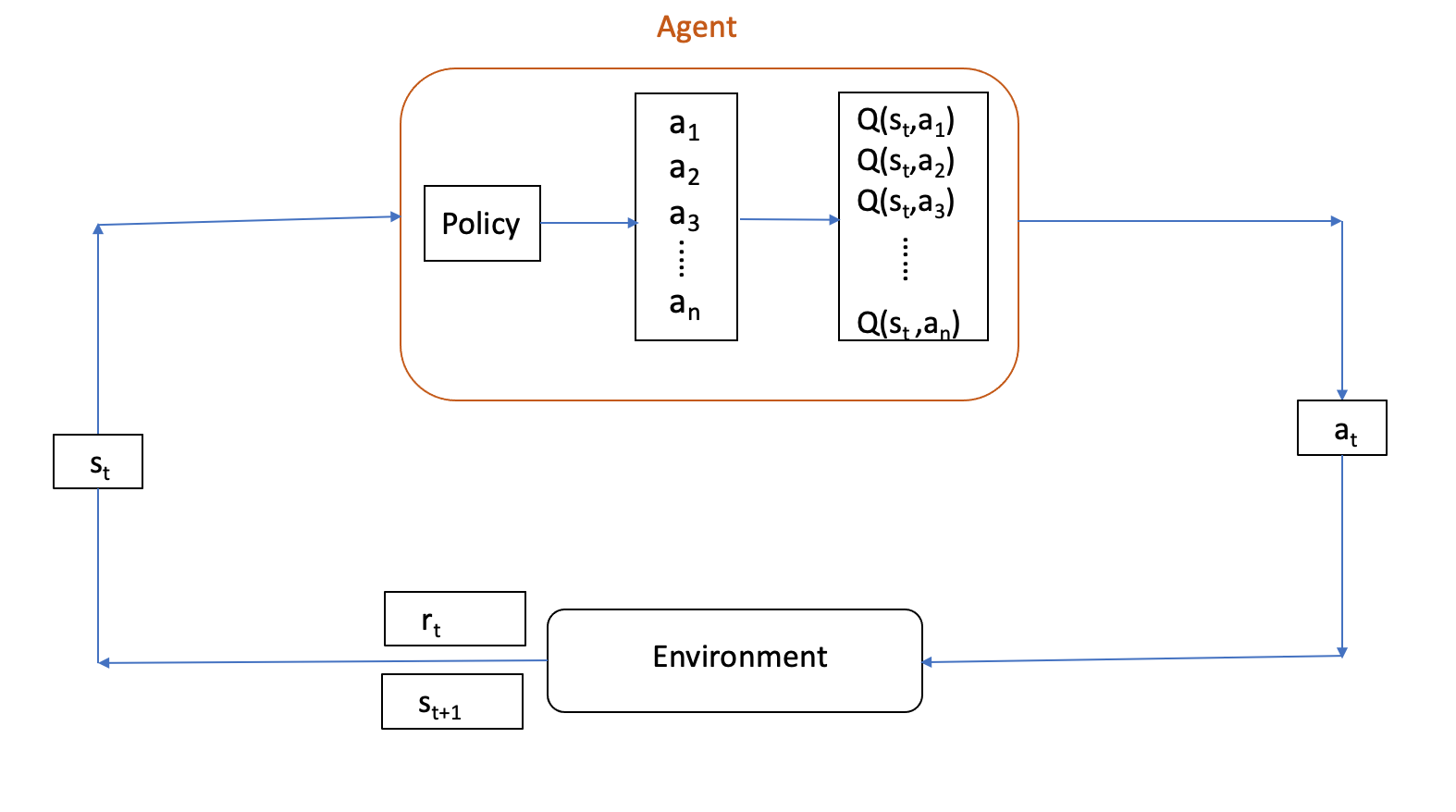

Learning based optimization and control

(Collaborator: Prof. Harikumar Kandath, IIIT Hyderabad; Prof Niket Kaisare, IIT Madras)

The performance of a model-based optimizer/controller is primarily dependent on the accuracy of the underlying model of the process. Even the slightest inaccuracies in the model will result in plant-model mismatch and, consequently, inaccurate prediction of the concentration profiles of the species from the model. Hence, there is much incentive if a control strategy can directly interact with process trajectory and provide a control solution for on-line course correction by learning the operational data profile. In this research vertical we employ principles of reinforcement learning, specifically actor-critic methods, to achieve the same.

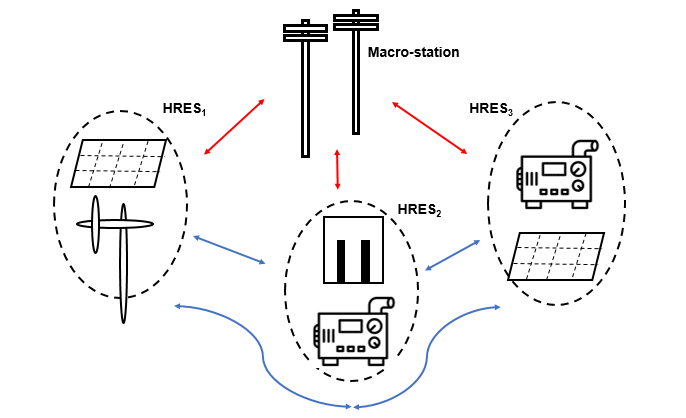

Optimal and sustainable operation of process systems

(Collaborators: Prof. Manojkumar Ramteke, IIT Delhi, Prof. Bhavik Bakshi, The Ohio State University, USA)

Due to the emergence of smart automation and Internet of Things (IoT), as a result of Industry 4.0, data archiving and exchange has become a routing task in industrial systems. This has also resulted in the availability of enormous amount of data in abundance, which can be used for analysis, synthesis and inference. In this work, using data analytics, black-box optimization, and model based / model free control strategies along with the principles of sustainable engineering and techno-ecological synergies, we coin a sustainable-optimal operational framework for process systems. The work will expand the system boundary to consider technological and socio- ecological systems in an integrated manner. Such an integrated system will help meet the economic goals of manufacturing and societal goals of a clean environment by modifying operation and design of the manufacturing system and of the affected socio-ecological system.<\p>

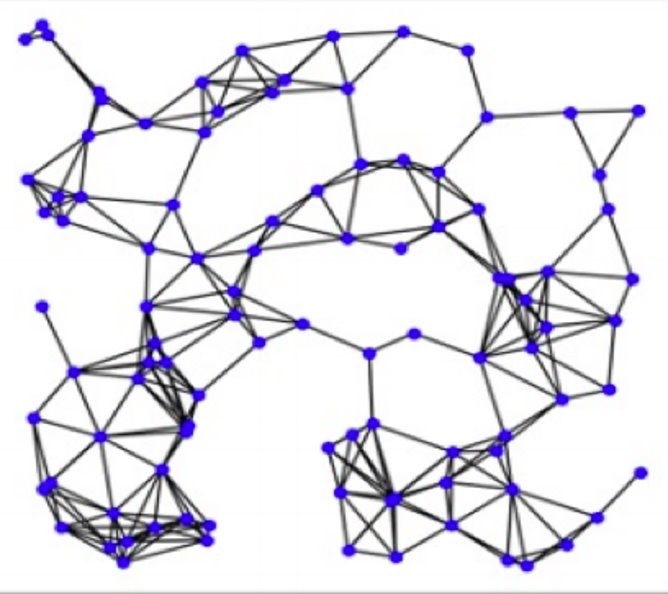

Generative modeling and anomaly detection of time series graph systems

(Collaborator: Prof. Sayan Ranu, IIT Delhi)

In this problem, we interest modeling of time series of networked systems that can be modelled graph. In this work package, we intent integrate graph neural networks and recurrent neural networks in a generative fashion to model networked systems. Further, using generative models we intent to check for operational anomaly detection of them by means of statistical methods.The proposed problem has applications to networked intelligent process systems, Intelligent manufacturing systems, Industry 4.0, and intelligent transportation networks, etc.<\p>

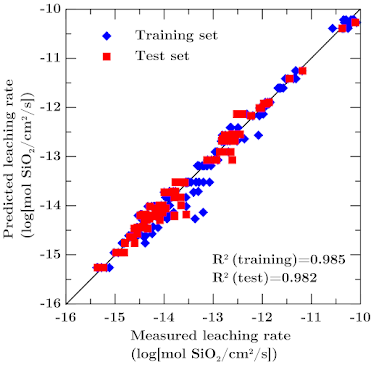

Machine Learning for material informatics

(Collaborator: Prof. Anoop Krishnan N M, Dept. of Civil Engineering and Dept. of Material Science and Engineering, IIT DELHI)

In materials, understanding and predicting the composition–structure–property relationship is the key to developing novel materials. Such predictions are typically hindered by the complex physics happening at different length and time scales, along with the large number of structural and compositional arrangements possible. As an alternative route, data-driven approaches such as machine learning can prove key to predict structure and composition of materials for tailored applications. The aim of this research is to rely on the large database available in the literature from previous experiments and simulations to design and test new compositions and structures of materials for targeted applications.