Research Areas

Background vector created by rawpixel.com - www.freepik.com

Research in M3RG is at the intersection of materials and mechanics. Our research philosophy is based on a two way informed analysis–design methodology wherein, first, the research focusses to develop a fundamental understanding of the material behavior. The knowledge gained from this improved understanding will be used to design materials for practical applications. This design then acts as a feedback mechanism in improving our understanding of complex material behavior. The main research areas we work on currently are as follows.

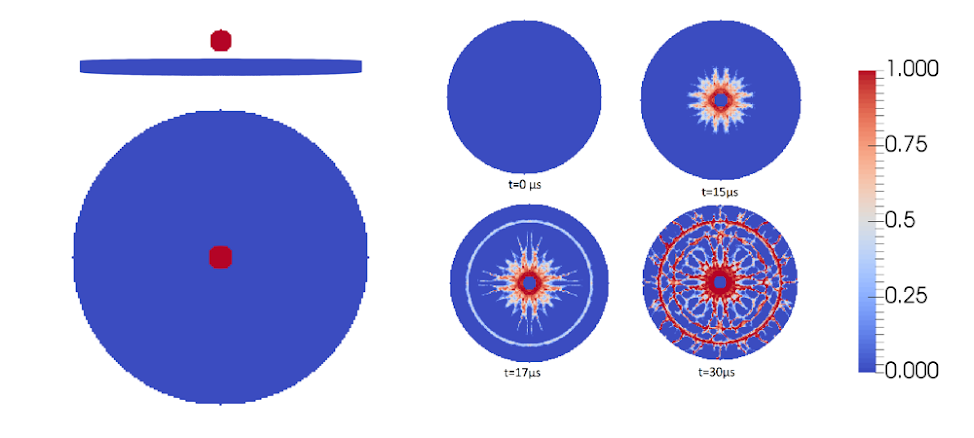

Peridynamics is an integral reformulation of the continuum equations of motion. Due to it’s inherent ability to deal with discontinuities in the displacement and stress fields, peridynamics is a highly useful method for studying dynamic fracture, impact-damage and explosion. The aim of this research is to understand the nature of crack propagation and failure in materials subjected to extreme loading such as bullet impact or explosion. The knowledge gained from the computational studies will be used to design novel materials with tailored design for impact and blast related applications.

Mechanics and kinetics of disordered nanomaterials

Nanomaterials such as carbon nanotubes and graphene hold unlimited potential, thanks to their superior mechanical and electronic properties. Recently, these materials have been found to exist in disordered forms as well, as a counterpart to their crystalline forms. The aim of this research is to understand the fundamental state of these disordered nanomaterials and to assess their mechanical properties, which could potentially open a new field of 2D glassy nanomaterials.

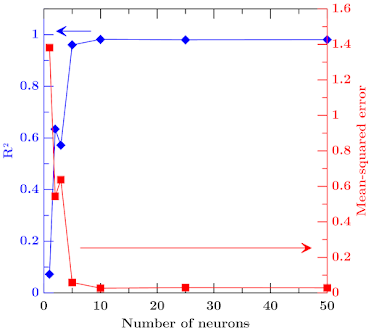

In materials, understanding and predicting the composition–structure–property relationship is the key to developing novel materials. Such predictions are typically hindered by the complex physics happening at different length and time scales, along with the large number of structural and compositional arrangements possible. As an alternative route, data-driven approaches such as machine learning can prove key to predict structure and composition of materials for tailored applications. The aim of this research is to rely on the large database available in the literature from previous experiments and simulations to design and test new compositions and structures of materials for targeted applications.

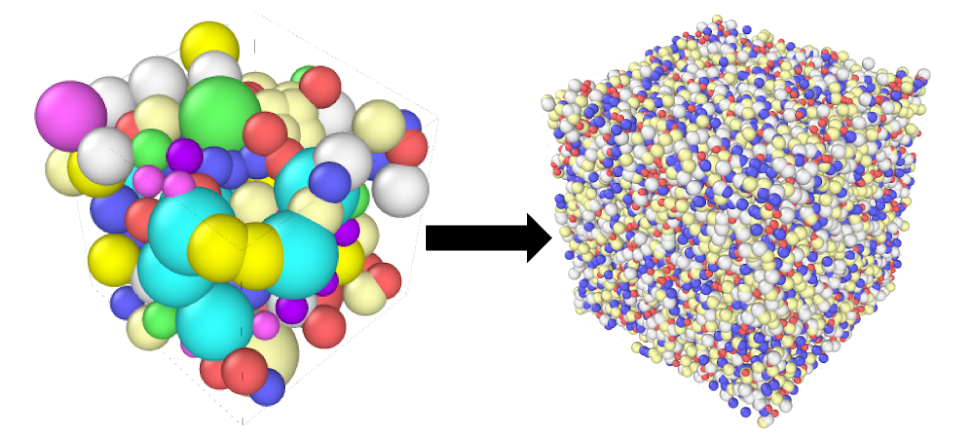

Cement hydrate exhibit a unique structure at the mesoscale, which holds the key to understanding and improving the behavior of cementitious materials. This is particularly important as cement manufacturing alone contributes more than 8% of the global CO2 production. The research aims to understand the effect mesoscale structure on the mechanical and kinetic properties of cement hydrate ranging from the plastic yielding to viscosity.

Nuclear waste immobilization

Nuclear wastes, produced by spent fuels of the nuclear power plants, are highly hazardous and are typically immobilized in glasses, namely borosilicate and phosphosilicate. The aim of this research is to develop a compositional map of borosilicate glasses suitable for nuclear waste immobilization in terms of processability, chemical durability, and stability.

Funding

-

INSPIRE Faculty award for the project titled, “Atomic and mesoscale modeling of radiation-damage in concrete”, Department of Science and Technology, India: 31/10/2017–30/10/2022 (INR 3,500,000).

-

SERB Early Career Researcher Award for project titled, “Elucidating Composition-Structure-Property Relationships in Silicate Glasses for Fracture- and Scratch-Resistant Applications”, Department of Science and Technology, India: 15/03/2019–14/03/2022 (INR 5,000,000).

-

SPARC project titled, “Design and Manufacturing of Ultra-high Velocity Bullet and Fragments Resistant Armor” with Indian PI: Prof. Naresh Bhatnagar (ME, IIT Delhi), Indian co-PI: Prof. N. M. Anoop Krishnan, International PI: Prof. Subramaniam D. Rajan (Arizona State University), International co-PI: Dr. Ashok Bhatnagar (Honeywell International), 15/03/2019–14/03/2021 (INR 10,000,000).

Press coverage

-

Machine learning software launched from M3RG to predict glass properties, PyGGi, featured in news. Do check it out at pyggi.iitd.ac.in

-

Research on realistic atomic structure of geopolymer gels chosen as Editor’s pick in JCP!

-

Research on the fracture of nanoscale phase-separated glasses chosen as Editor’s suggestion in Phys. Rev. Materials!

-

Research on the effect radiation on quartz was featured in news article!

link1

link2

link3

link4