|

|

read more.. |

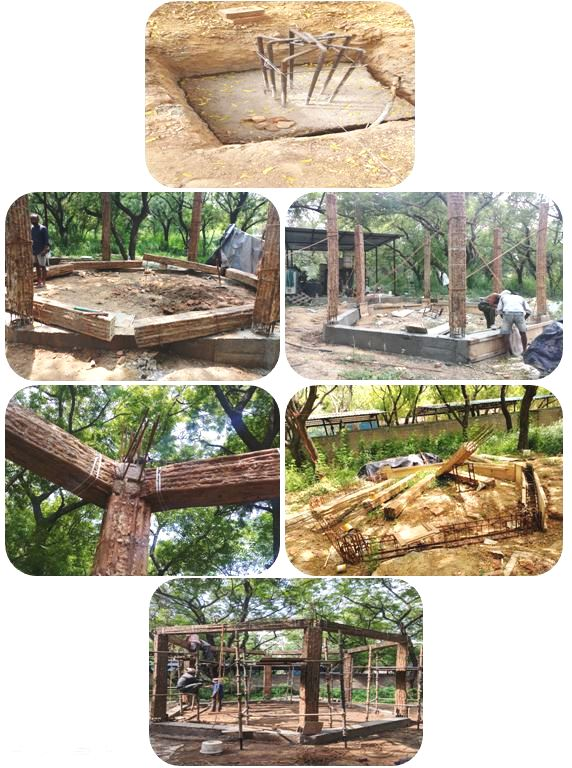

Construction of Prototype House in Progress at Mahatma Gandhi Gramodaya parisar (Micromodel IIT delhi)

STEPS IN PROGRESS FOR THE CONSTRUCTION OF PROTOTYPE HOUSE (Gow-Crete brick wall construction)

STEPS IN PROGRESS FOR THE CONSTRUCTION OF PROTOTYPE HOUSE

HEXAGONAL STRUCTURE OF PRE-FEBRICATED ELEMENTS MEASURING 25 sqm AREA

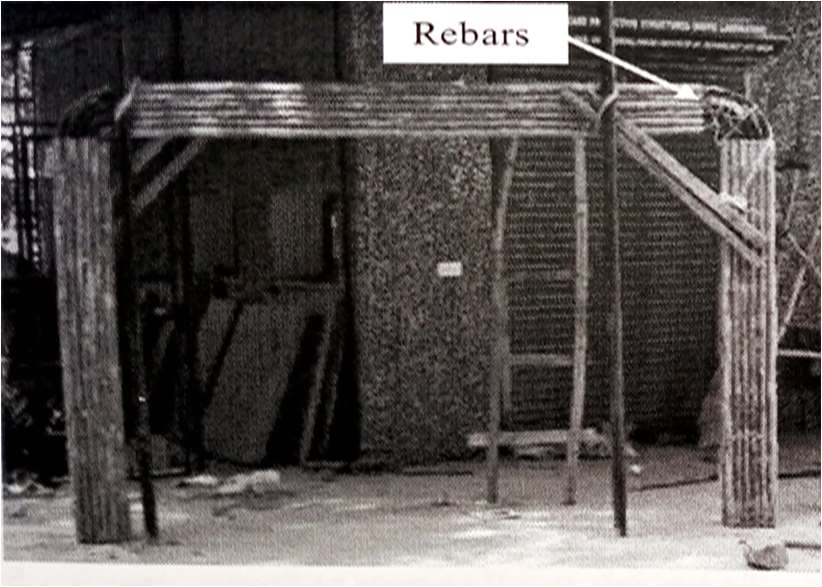

Light battened bamboo structure for light load

Lightly loaded temporary bamboo struct exp.

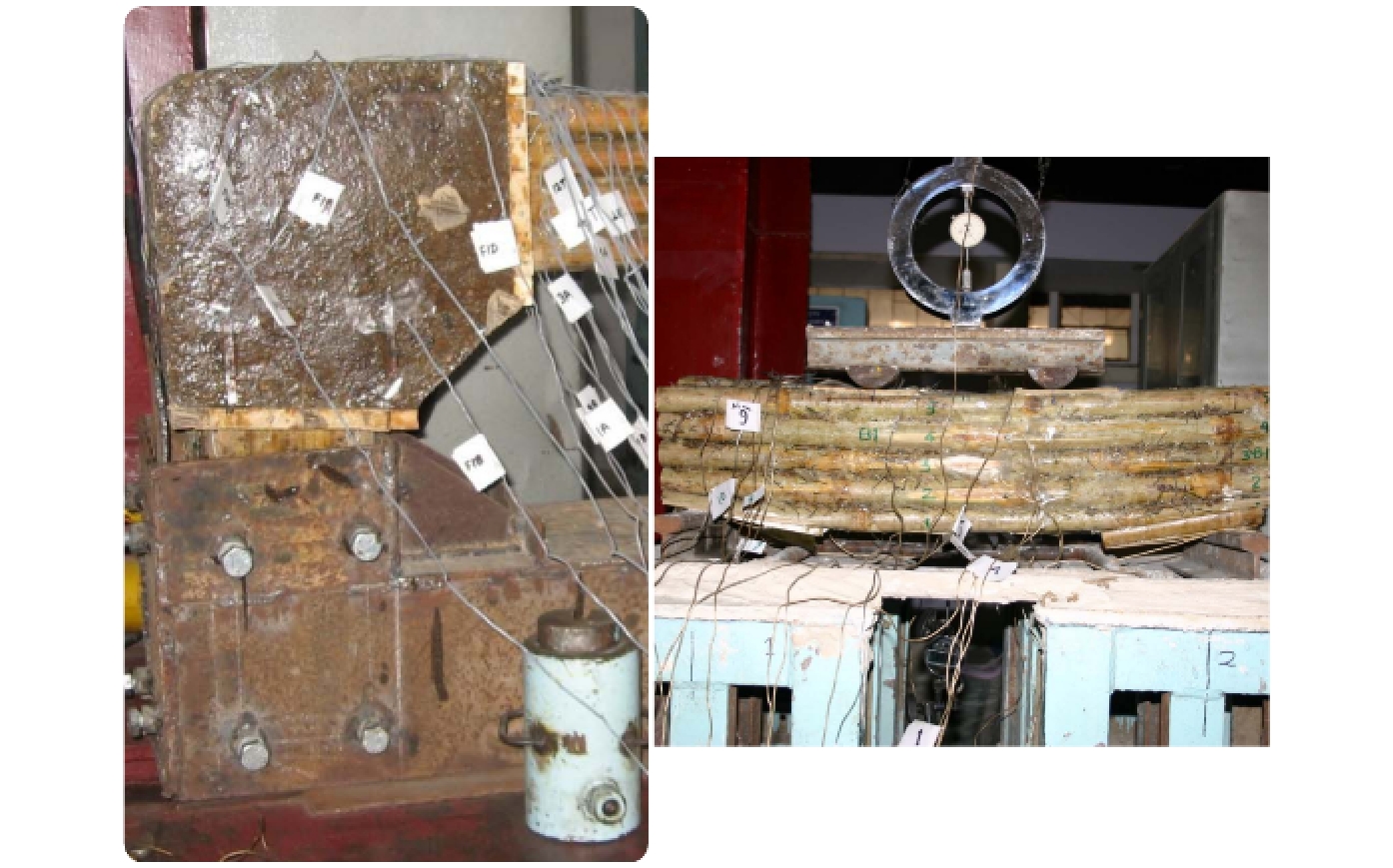

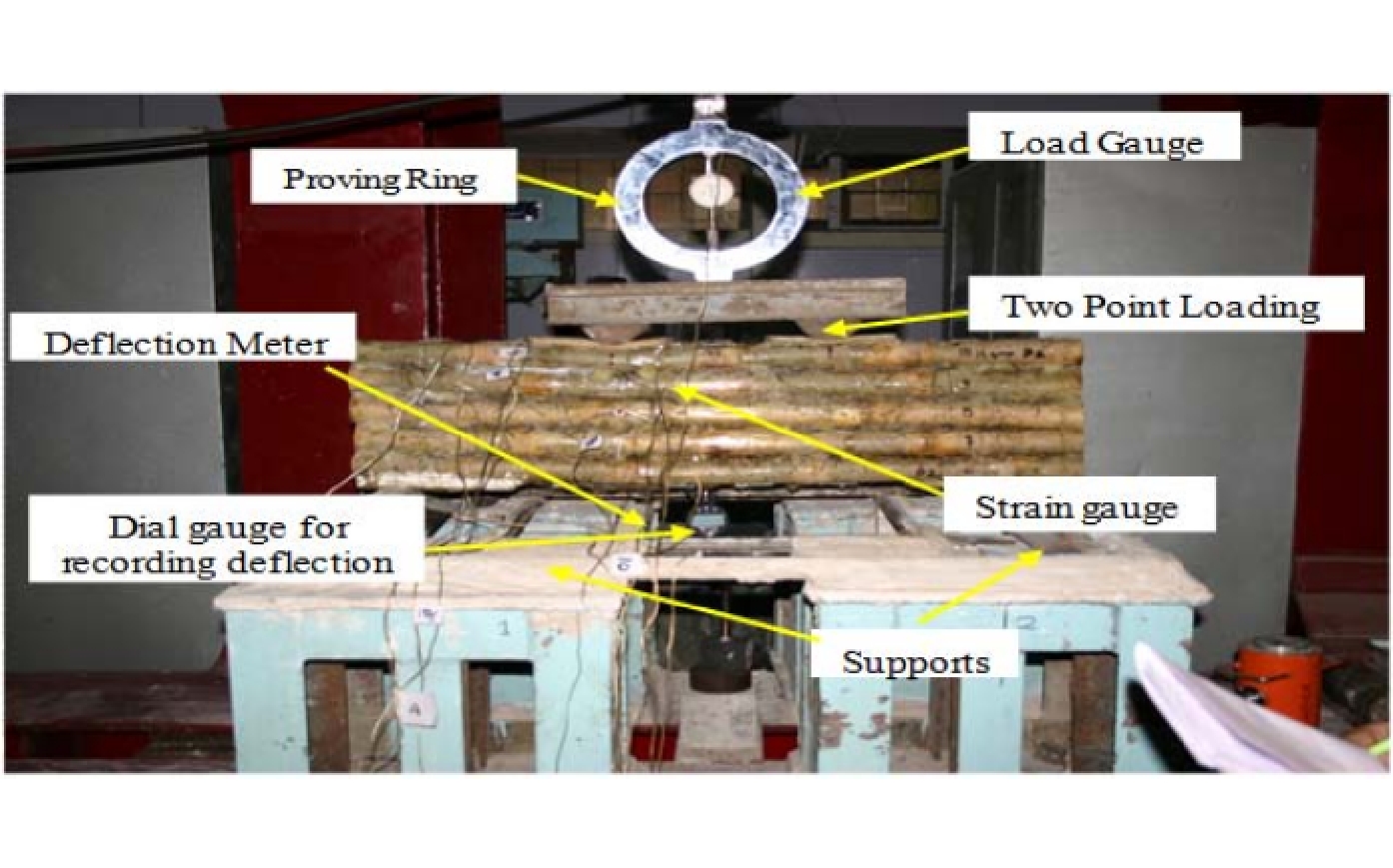

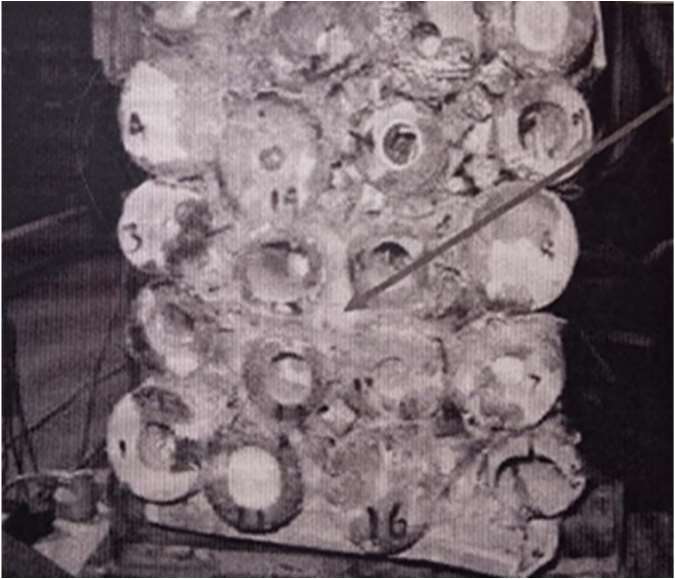

Specimen of Bamcrete beams & column

under load deflected hexagon frame

Properly tightened end shown bending

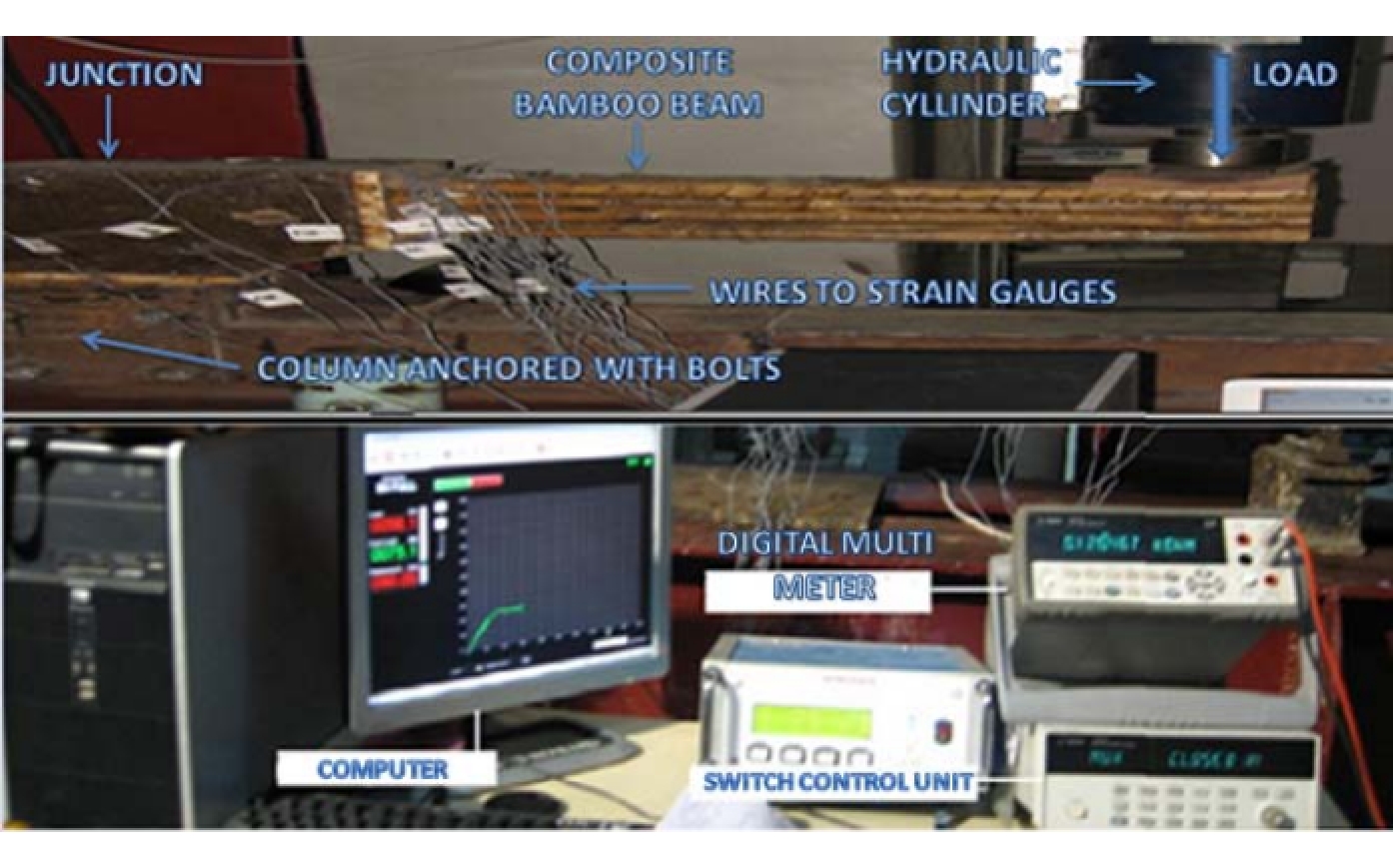

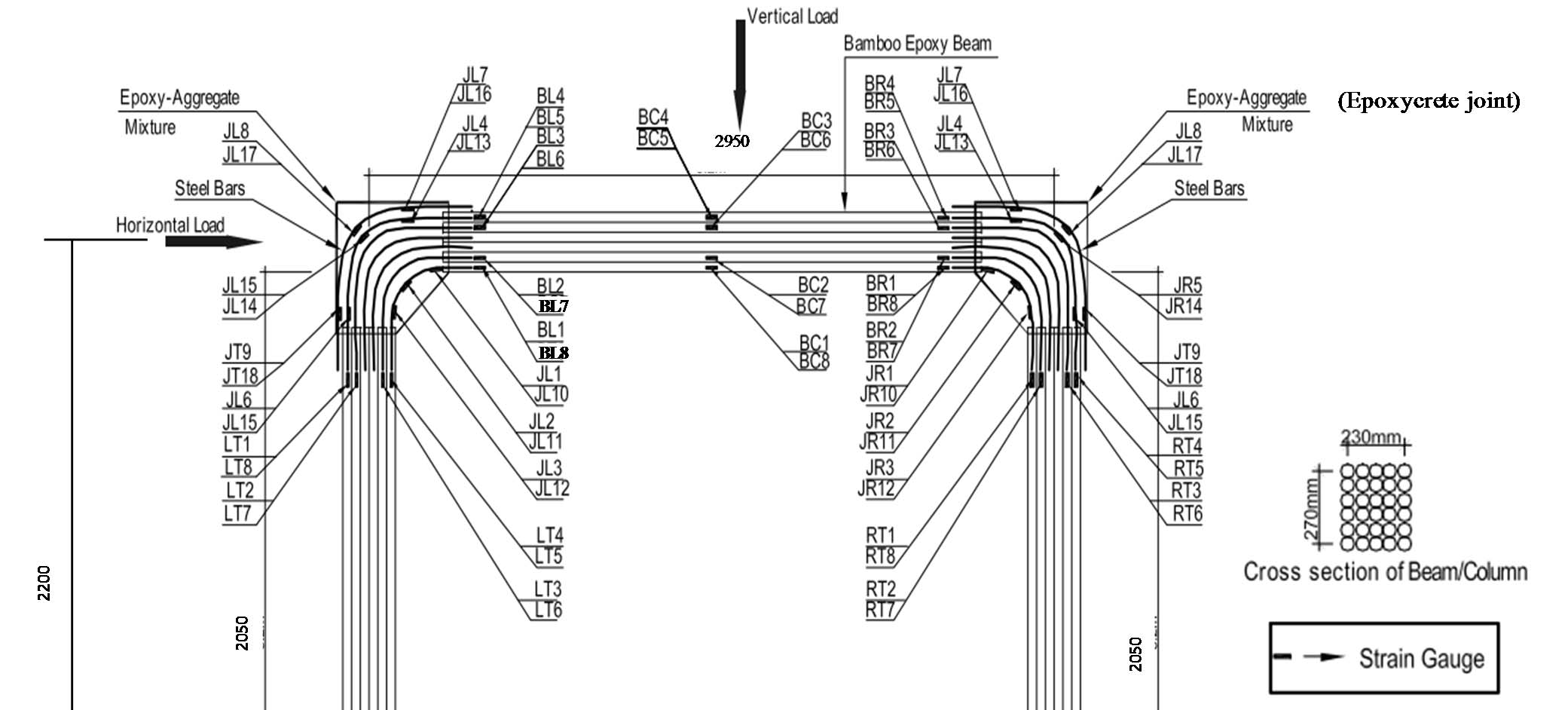

Portal Under Combined Load Application Mechanism

|

|||||||||||||||||

| ||||||

|

|

|

|

|

|

|

|

|

Dr. Suresh Bhalla Professor Department of Civil Engineering, IIT Delhi Principal Investigator E-mail: sbhalla@civil.iitd.ac.in

|

|||||||||||||||||

|

Dr. Sumit Balguvhar Senior Project Scientist Department of Civil Engineering Indian Institute of Technology Delhi (IITD) Hauz Khas, New Delhi 110 016 E-mail: ersumitest@gmail.com | |||||||||||||||||

| Mr. Himanshu Kashyap IIT Delhi Staff E-mail: hmkashyap321@gmail.com |

||||||||||||||||||