Bicycle based agriculture equipment (Academic Project)

Problem Statement

To facilitate the cutting and mulching of crops like wheat, mustard, leaves etc using a bicycle driven cutting equipment in order to ease the existing conventional system.

Concept

Being engineers, We wanted to innovate something new, that could really bring a change in someone’s life. With this thought and interest in Product design and development, we decided to work in this field under the supervision of Dr. Ankit Bansal, Assistant Professor, IIT Roorkee for the course Lab based Project.

Approach to the problem

We had a team of 4 for this project

1. Ujjwal Sharma

2. Utsav Rajpal

3. Vinod Kumar

4. Vaibhav Agarwal

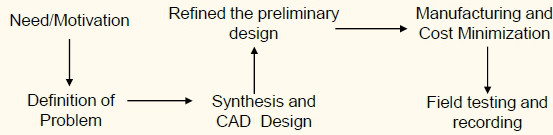

The following figure shows the progress made by us in bringing the design of ‘Bicycle based Agricultural equipment’ from random sketches of paper to reality.

After brainstorming for few days, we came up with the notion to develop the agricultural equipment for rural areas. We planned to make a manual, affordable and efficient equipment that can serve the required purposes with ease.

We recognize that the manual or conventional process of cutting crops is very tedious and time consuming. Alternatives present are very costlier (Min ₹12000), bulky, need expertise and are not affordable for each and every farmer. So, after giving our thought process on this issue, we came up with the idea of a detachable cutting assembly in the front portion of the bicycle. With this notion, we carried out our work and identified the required problem statement for this project.

Preliminary Design

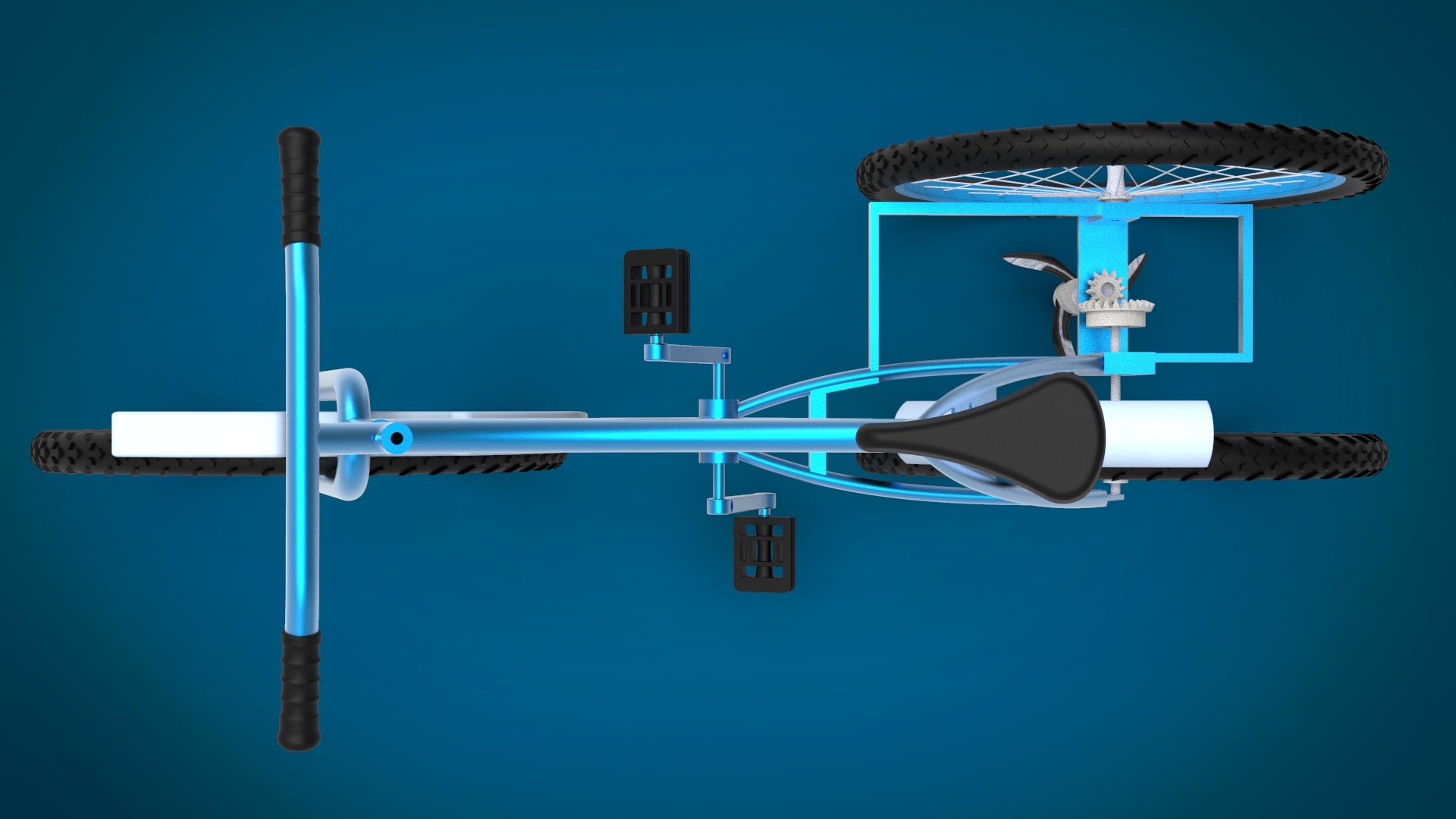

After discussion we came up with the idea of attaching the cutting blade to the side section of the bicycle. This is the CAD render of the preliminary design.

Isometric view of the preliminary design

Top view of the preliminary design

Problems identified in previous design

1. Operator cannot observe the cutting action.

2. Ergonomically unstable design.

3. Only sideways cutting to crops possible.

4. Issues related to CG. (Centre of gravity).

5. Difficulty in providing extra support to rear structure (Welding limitations).

6. Costlier arrangements were required to transverse motion from rear tyre to bevel gears.

7. Requires higher torque which will cause fatigue in operator

Final Design

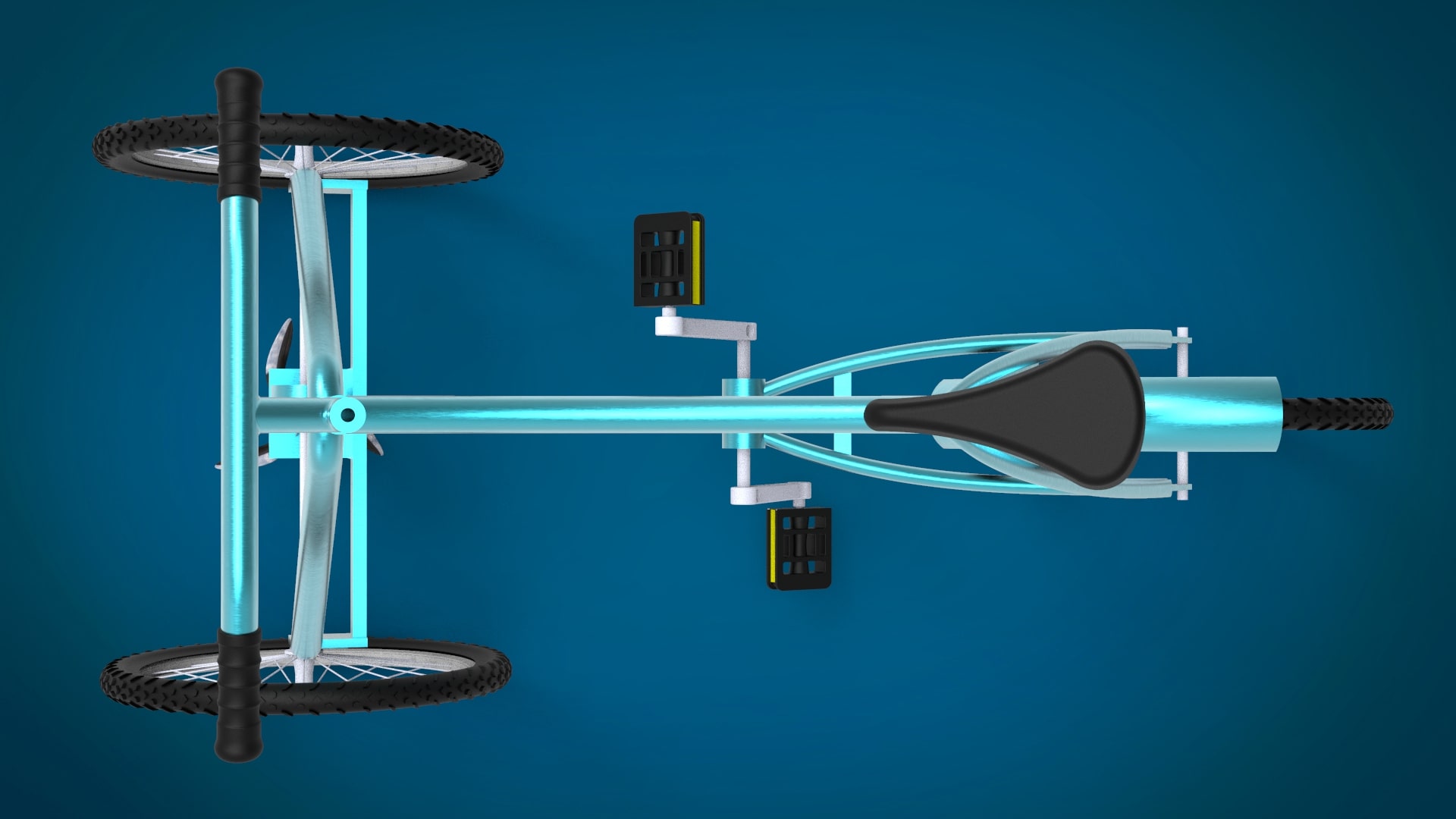

Top view of the final design

Isometric view of the final design

Characteristics of final design

1. Operator can easily observe the cutting action

2. Ergonomically more stable design

3. Cutting of crops can be done through any section of the field

4. CG is now in centre of the equipment (Lesser chances of toppling)

5. Stable and user-friendly frame design

6. Affordable, efficient and more effective than previous design

7. No more work fatigue on operator (Requires lesser torque)

Manufacturing of final design

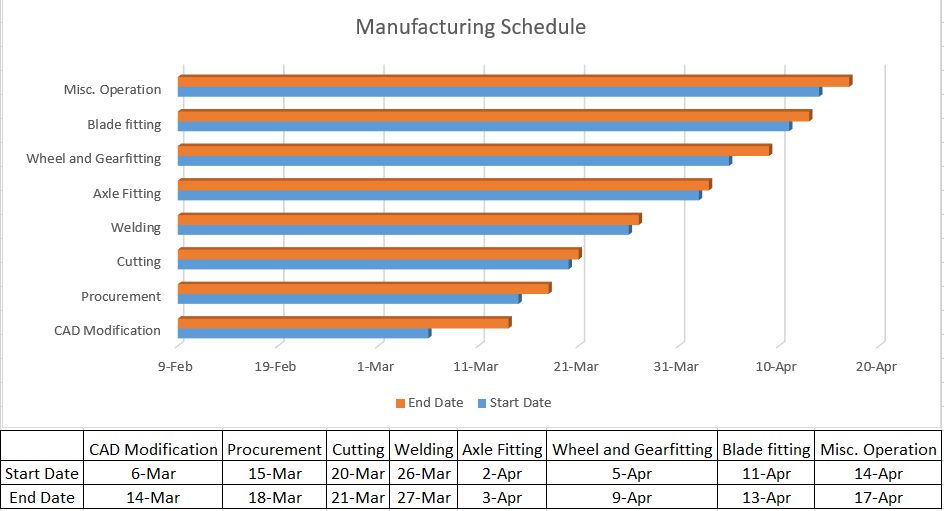

After finalization of design, the next process is manufacturing. The following chart shows different manufacturing processes with their start and end dates for the production of bicycle based agricultural equipment.

Manufacturing Processes

1. Procurement

2. Cutting

3. Welding

4. Axle Fitting

5. Gear Fitting

6. Blade Fitting

7. Final touchup

Gaps and barriers identified in manufacturing:

1. Welding and alignment of frame on front wheels axle.

2. Pin mechanism for blade engagement & disengagement with vertical gear.

3. Aligned coupling of Bevel gears.

4. Weight reduction for front part assembly. (Use of hollow pipes)

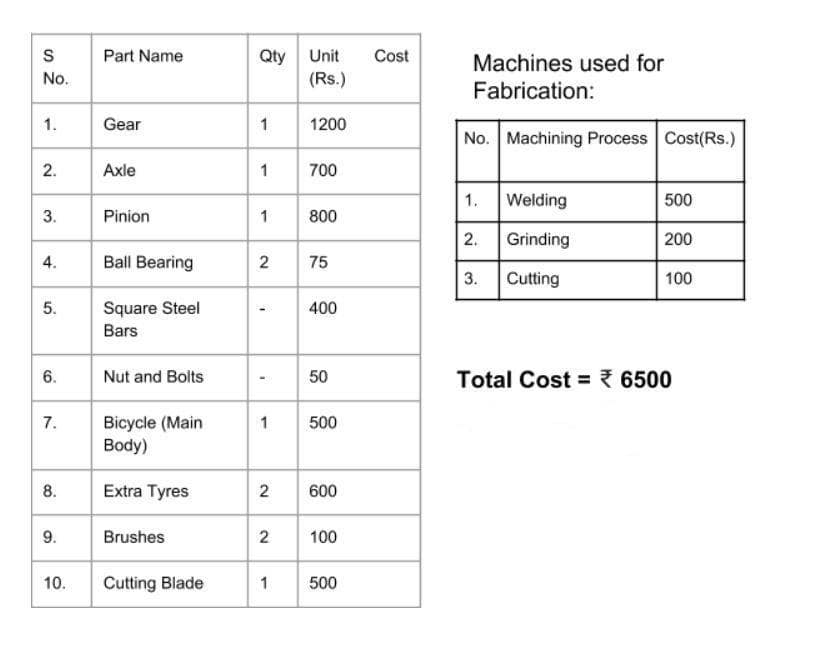

Cost Analysis

A total of Rs.6500 expense was made which also includes the cost of experimentation. This cost can be further reducded by mass manufactring the product.

Results

Front assembly of manufactured product

Cutting blade of the agriculture equipment

Future Improvements

1. Better Suspension system can be incorporated

2. Centre of gravity can be made closer to ground level (provided via inclination

of front wheels arrangement)

3. Wider tyres can be employed for better traction

4. Mechanical advantage of the cutting blade can be improved

5. More customizable design can be made

6. Clutch system can be incorporated so as to engage or disengage the blade

when required

7. Multiple gear drives can be incorporated in pedal mechanism resulting in lesser

work fatigue

8. Frame modifications for swiping crops (after cutting)