|

|

| Vivek V. Buwa | |

| Multi-scale Simulations | |||||||||||||||||||

|

Particle-Scale Flow in Packed Beds |

|||||||||||||||||||

|

Packed bed reactors with random packing of particles are widely used in chemical process industries to perform single or multiphase catalytic reactions due to their high surface area to volume (STV) ratio. Particles are often spherical or cylindrical in shape, but other shapes with different internal structures (voids) or external shapes are reported in the literature. Fluid flows over catalyst particles and reactions and heat transfer take place simultaneously on the external (particle-scale) and internal (pore-scale) surfaces of the particles. Particle shape influences the local fluid flow (in the vicinity of the particle) which contributes to the pressure drop (dP), heat and mass transfer and therefore the reactor performance. So, the performance of these reactors can be improved by understanding the complex interactions between the catalyst particles and the surrounding flow field. However, limited information is available in the literature for the choice of particle shapes and its impact on the reactor performance. Therefore, the main objective of our research work is to establish a relationship between the particle shape and reactor performance. This knowledge will help in the development of better particle shape to improve the reactor performance. |

|||||||||||||||||||

| Effect of Particle Shape on Fluid Flow and Heat Transfer for Methane Steam Reforming Reactions in a Packed Bed | |||||||||||||||||||

|

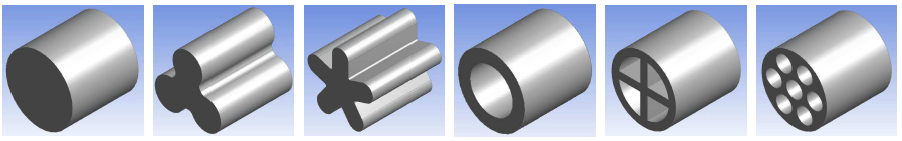

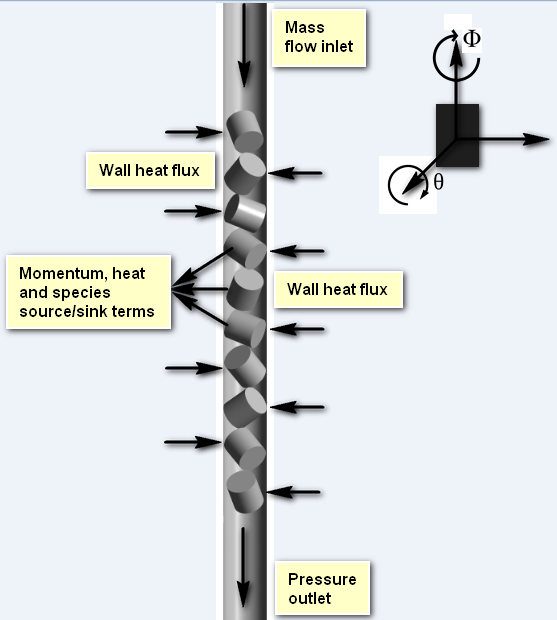

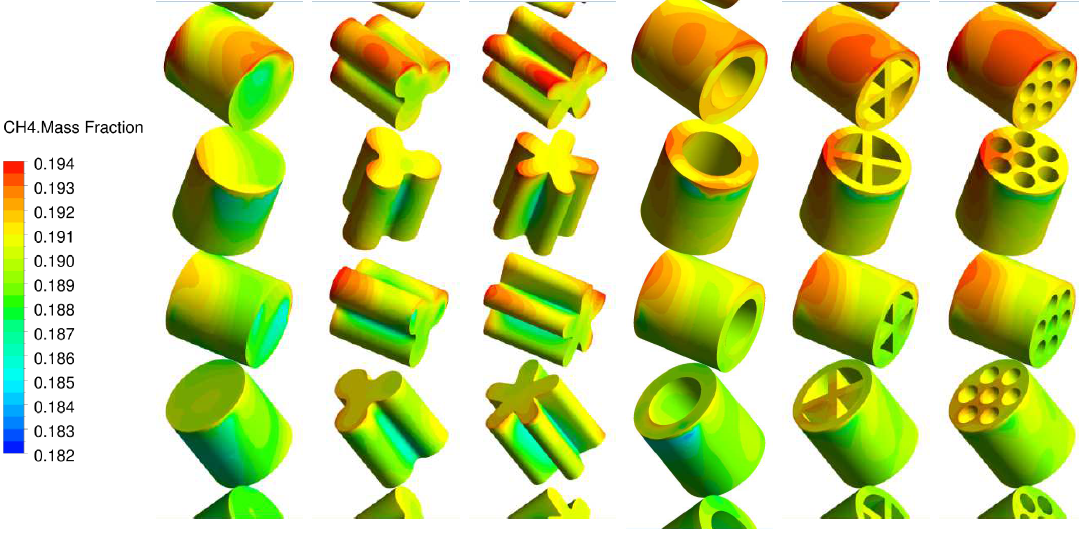

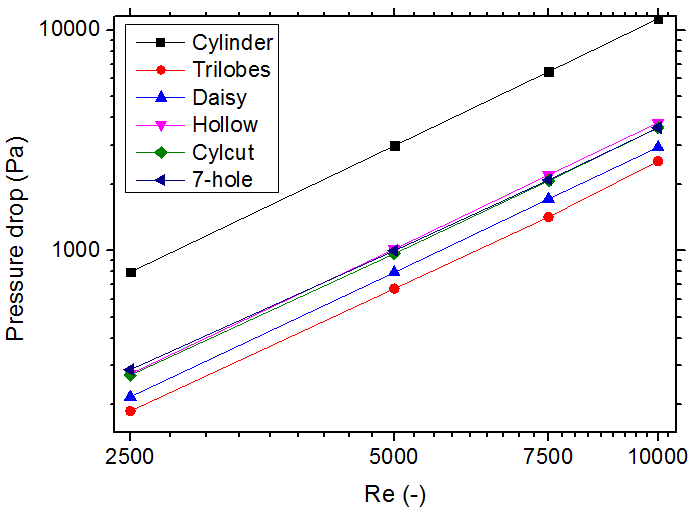

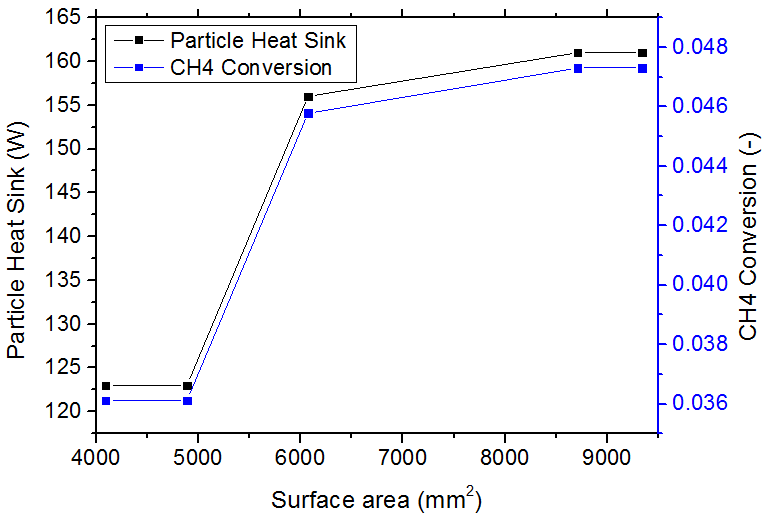

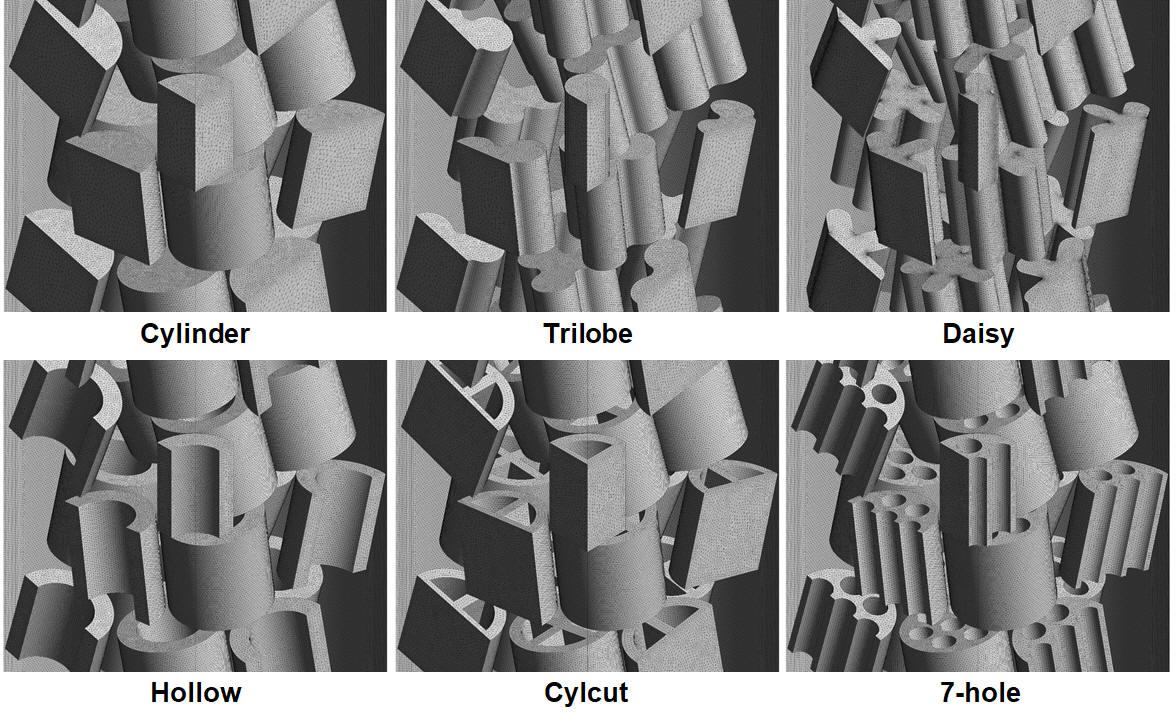

Numerical simulations of a cylindrical packed bed with tube to particle diameter ratio of 1.4, containing 10 particles, were performed to understand the effect of particle shape on pressure drop, heat transfer and reaction performance. Six particle shapes namely, cylinder (as the reference), trilobe and daisy (having external shaping), hollow cylinder, cylcut, and 7-hole cylinder (including internal voids) were chosen. Methane steam reforming reactions were considered for the evaluation of heat transfer and reaction performance. The present study showed that the external shaping of particles offered lower pressure drop, but also lower values of effectiveness factor indicating strong diffusion limitations. The internally shaped particles offered increased surface area, this led to higher effectiveness factor and also allowed to overcome the diffusion limitations. The effective heat transfer and effectiveness factor of the trilobe-shaped particle per unit pressure drop was found to be the best among the particle shapes considered in this work. |

|||||||||||||||||||

|

|

||||||||||||||||||

|

Packing shapes and typical mesh considered in the present work: (i) cylinder, (ii) trilobe, (iii) daisy, (iv) hollow cylinder, (v) cylcut and (vi) 7-hole cylinder. |

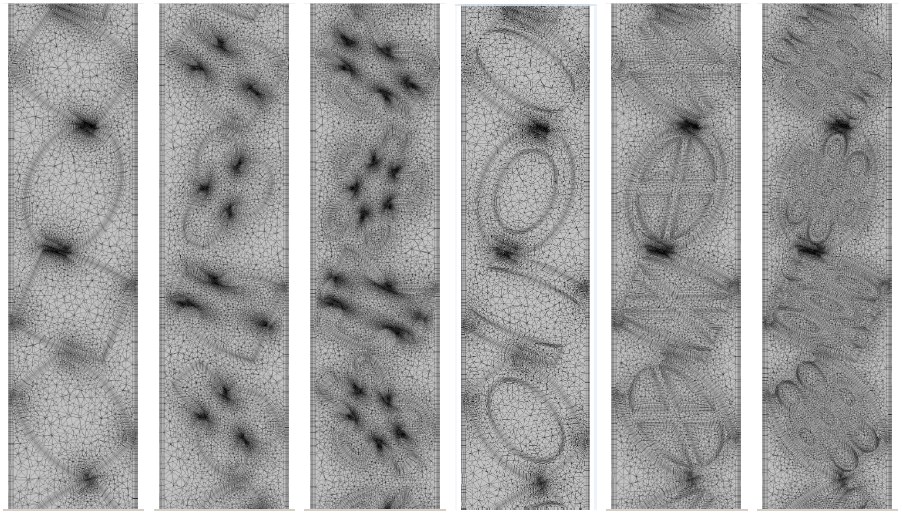

Final particle packing arrangement considered in the present work and the boundary conditions. | ||||||||||||||||||

|

|

||||||||||||||||||

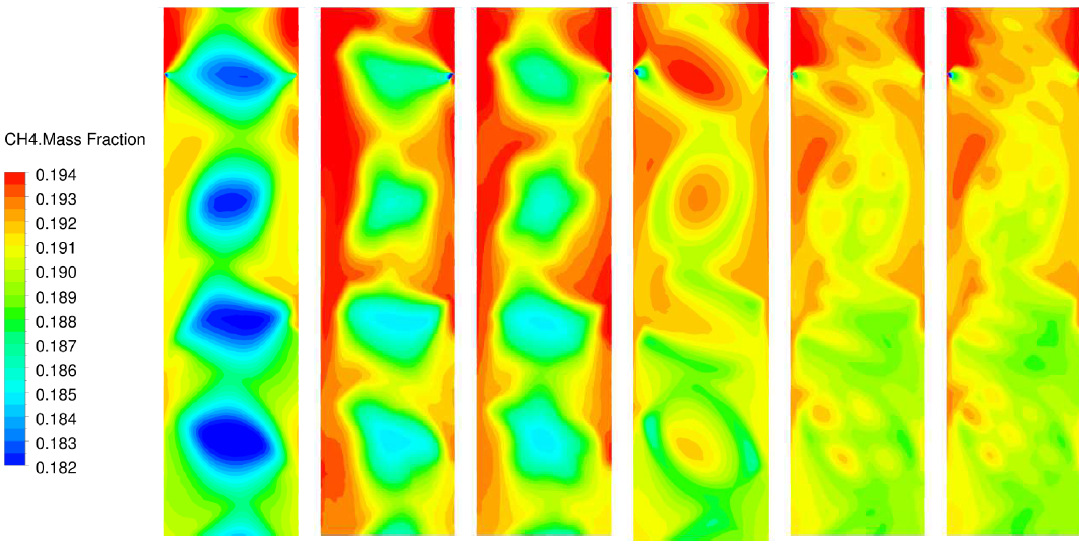

| Simulated temperature distribution on particle surfaces for Re= 5000: (i) cylinder, (ii) trilobe, (iii) daisy, (iv) hollow cylinder, (v) cylcut and (vi) 7-hole cylinder. | Simulated CH4 mass fraction distribution on r-z plane for Re= 5000: (i) cylinder, (ii) trilobe, (iii) daisy, (iv) hollow cylinder, (v) cylcut and (vi) 7-hole cylinder. | ||||||||||||||||||

|

|

||||||||||||||||||

| Effect of particle shape on pressure drop at different Re. | Effect of particle surface area on heat sink and CH4 conversion for Re= 5000. | ||||||||||||||||||

| Particle-resolved Simulations of Methane Steam Reforming in Multi-layered Packed Beds | |||||||||||||||||||

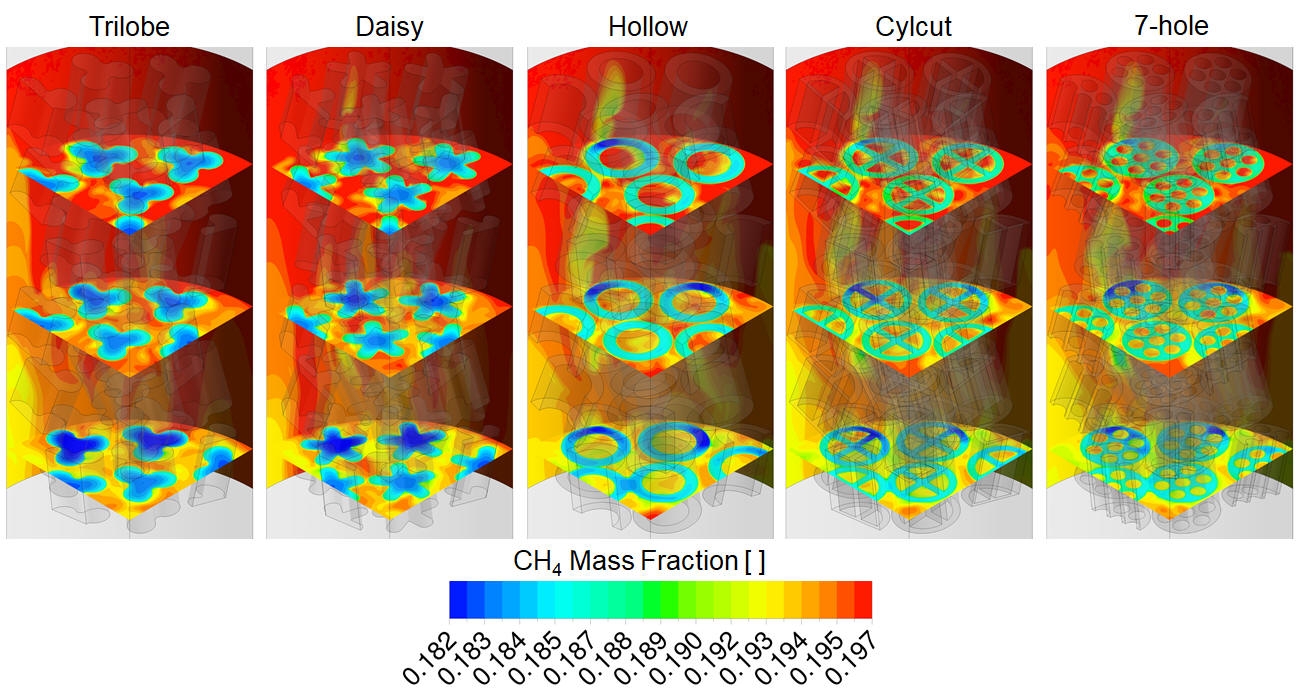

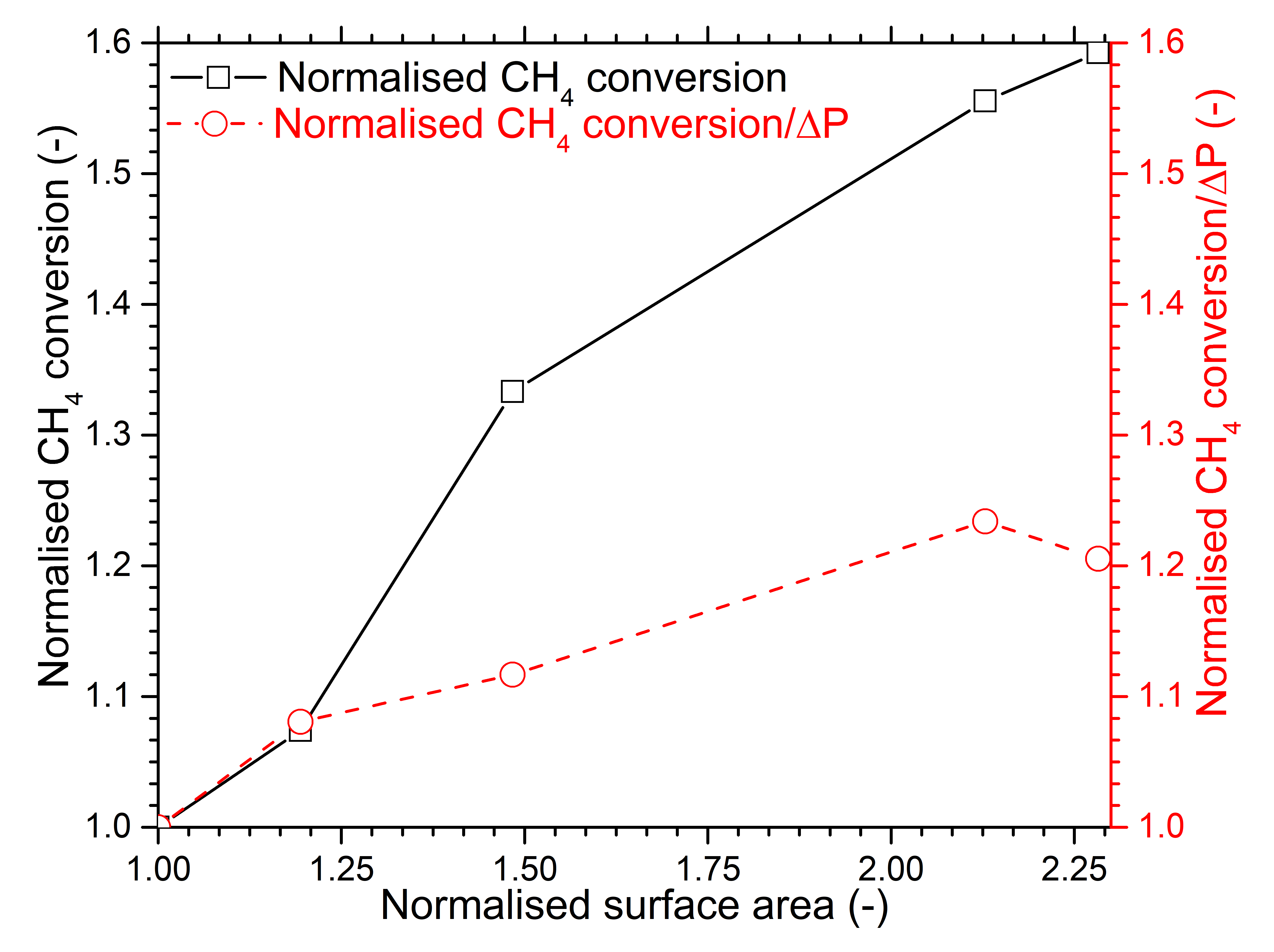

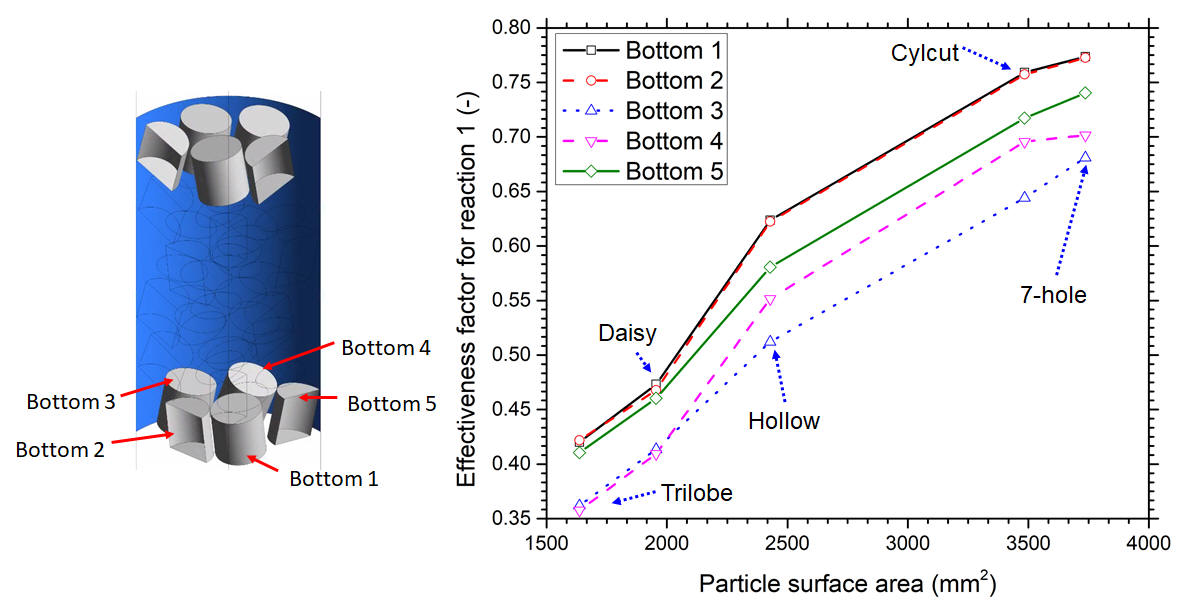

| Particle-resolved CFD simulations of multi-layered packed beds containing 30 particles of different particle shapes (trilobe, daisy, hollow cylinder, cylcut and 7-hole cylinder) with tube to particle diameter ratio of 5, were performed to understand the effects of particle shape on pressure drop (dP), dispersion, CH4 conversion and effectiveness factors for methane steam reforming reactions. The effects of different boundary conditions and particle modelling approaches were analyzed in detail. The empirical correlations available in the literature (Ergun and Zhavoronkov et. al) over-predicted the dP, and therefore, a modified correlation was developed to predict dP for the particles with different shapes. Overall, the externally-shaped particles (trilobe and daisy) offered lower dP and higher dispersion due to the lower surface area and higher back flow regions, whereas due to the better access for the reactants, the internally-shaped particles (cylcut, hollow and 7-hole cylinder) offered higher CH4 conversion and effectiveness factors. The cylcut shape offered the highest CH4 conversion/ dP. | |||||||||||||||||||

|

|

||||||||||||||||||

| Final particle packing arrangement considered in this work with the boundary conditions. | Typical mesh for different particle shapes. | ||||||||||||||||||

|

|

||||||||||||||||||

| Simulated temperature distribution on different cross-sectional planes at Re= 50000. | Simulated CH4 distribution on different cross-sectional planes at Re= 50000. | ||||||||||||||||||

|

|

||||||||||||||||||

| Effect of particle surface area on normalised (w.r.t trilobe) CH4 conversion and normalised (w.r.t trilobe) CH4 conversion per unit pressure drop for Re= 50000. |

Effect of particle position on effectiveness factor and different

shapes at Re= 50000. |

||||||||||||||||||

|

|

|||||||||||||||||||

| Effect of Particle Shape on Catalyst Deactivation Using Particle-Resolved CFD Simulations | |||||||||||||||||||

| A method has been demonstrated using particle-resolved CFD simulations to simulate the transient catalyst deactivation due to carbon formation process and its impact on the particle properties (porosity, density, specific heat and thermal conductivity). Preliminary simulations with cylindrical shaped particles and propane dehydrogenation reactions showed higher carbon accumulation in the particles located near the wall due to presence of wall heat flux. The significant gradients of carbon concentration within the particle pointed to the presence of diffusion limitations. The propene formation decreased with time as the reaction rates decreased due to increase in the accumulated carbon. Later, the effect of particle shape on the catalyst deactivation was investigated using five different particle shapes with constant particle volume, but varying in particle surface area. Considerable variations in the accumulated carbon were observed both with respect to the particle position and the particle shapes. Due to reduced diffusion limitation, the initial reaction rate increased with the particle surface area. However, due to faster catalyst deactivation, the reaction rate was found to decrease after certain time. As a result, the propane conversion and propene yield decreased with particle surface area. Also, the propene yield to dP ratio decreased with particle surface area due to smaller dP offered by particles with lower surface area. The present work showed that the particles with lower surface area are favorable for propane dehydrogenation process due to slower catalyst deactivation leading to higher conversion and longer operating time. The trilobe particle shape gave the highest propane conversion and highest propene yield to dP ratio. | |||||||||||||||||||

|

|||||||||||||||||||

| PIV-LIF Measurements and CFD Simulations of Particle-Scale Flow and Tracer Distribution in Packed Beds | |||||||||||||||||||

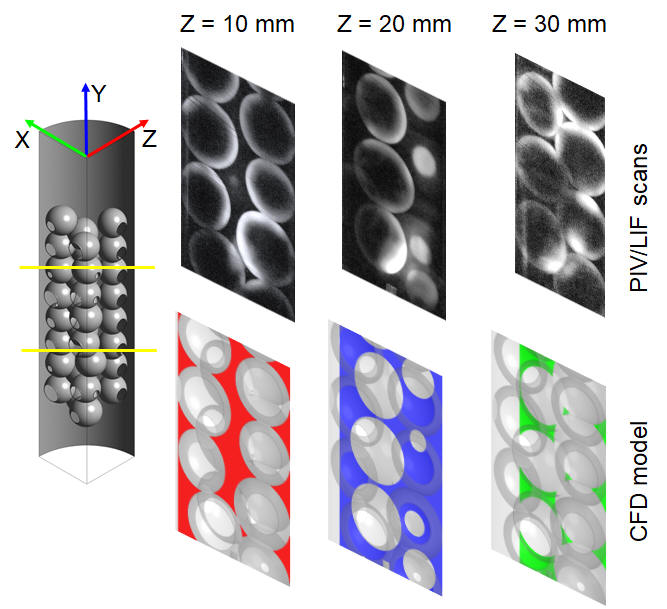

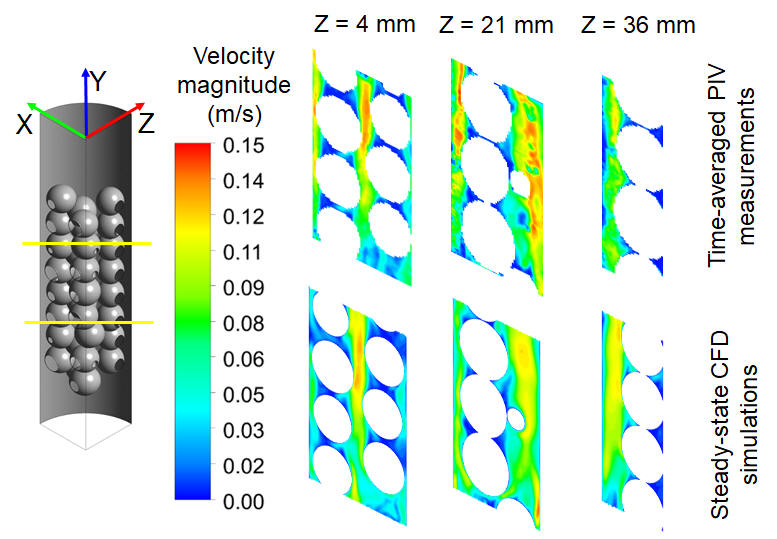

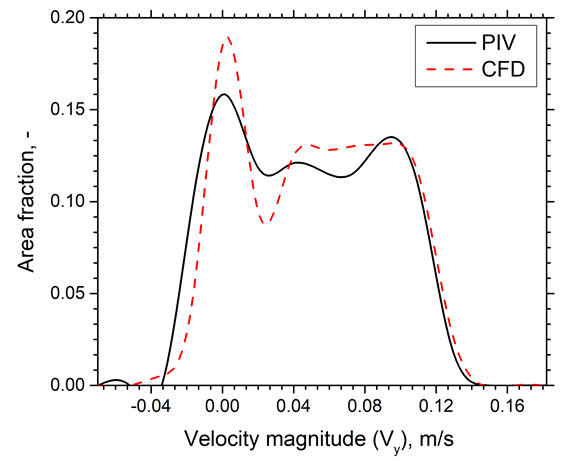

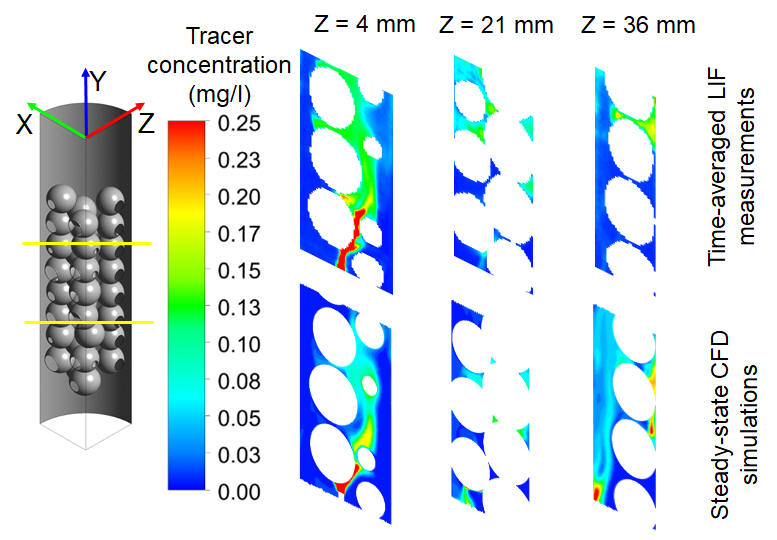

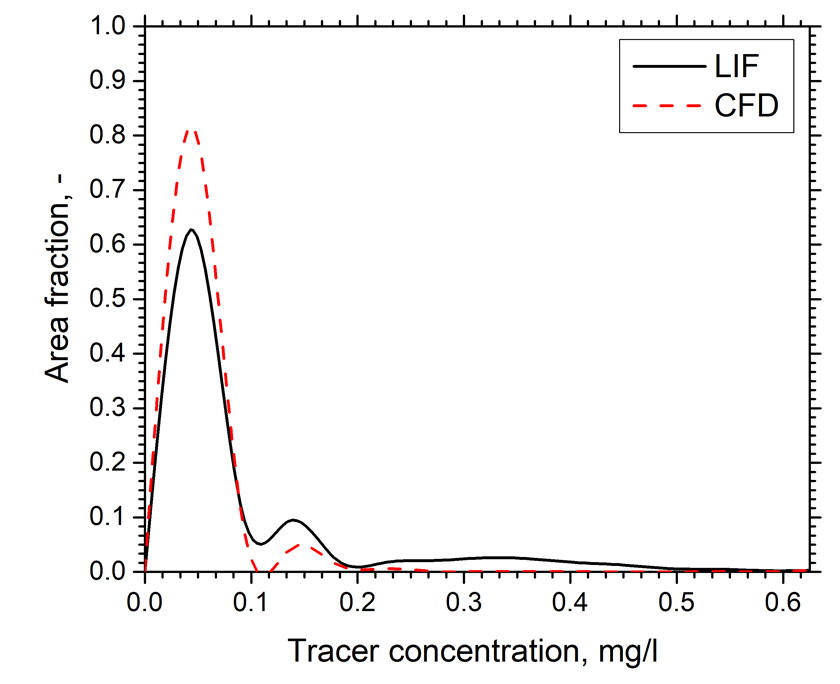

| The main objectives of this work are (a) to demonstrate a simple yet effective methodology for CFD geometry reconstruction from PIV/LIF scans with good accuracy and also provide information on sensitivity of key geometry parameters, (b) to compare the CFD predictions with PIV measurement in the turbulent flow regime by comparing the velocity, vorticity, strain rate and turbulent parameters and (c) to compare the CFD predictions with LIF measurement in the turbulent flow regime by comparing the species concentration. The results showed a reasonable agreement between the CFD (SST k-w turbulence model) and PIV measurments for velocity, voriticty and strain rate distribution whereas significant deviations were observed for turbulent quantities (turbulent kinetic energy and turbulent eddy dissipation). Also, the tracer concentration distribution showed similar trend, however, the magnitudes were different between the CFD and LIF measurements. The deviations are mainly attributed to the differences between the experimental and simulated geometry mainly the particle position, trace nozzle orientation and also the turbulence model. | |||||||||||||||||||

|

|

||||||||||||||||||

| Experimental setup used for PIV and LIF measurements. | Methodology followed for generation of CFD model using PIV/LIF scans. | ||||||||||||||||||

| Comparison of PIV measurments and CFD simulations | |||||||||||||||||||

|

|

||||||||||||||||||

| Velocity magnitude distribution over combined X-Y planes at Z = 4, 21 and 36 mm (Rebed = 2200). | Probability distribution of Y-velocity, Vy magnitude over combined X-Y planes at Z = 4, 21 and 36 mm (Rebed = 2200). | ||||||||||||||||||

|

|

||||||||||||||||||

| Tracer concentration distribution over combined X-Y planes at Z = 10,20 and 30 mm (Rebed = 2200). | Probability distribution of tracer concentration over combined X-Y planes at Z = 10, 20 and 30 mm (Rebed = 2200). | ||||||||||||||||||

| Scientific Contributions | |||||||||||||||||||

| International Journals | |||||||||||||||||||

|

|||||||||||||||||||

|

International & National Conferences |

|||||||||||||||||||

|

|||||||||||||||||||