Gulshan Kumar

Fusion 360 makes top-down assembly much easier, as it let us create components and edit everything as though they were one. This can help designers to think about their work in terms of a cohesive finished product rather than single parts, one at a time. Fusion 360 has a very simple, intuitive user interface. One of the main advantage for using fusion 360 is student free license.

Making a coffee mug.

Before making any 3d model we should have a clear idea about

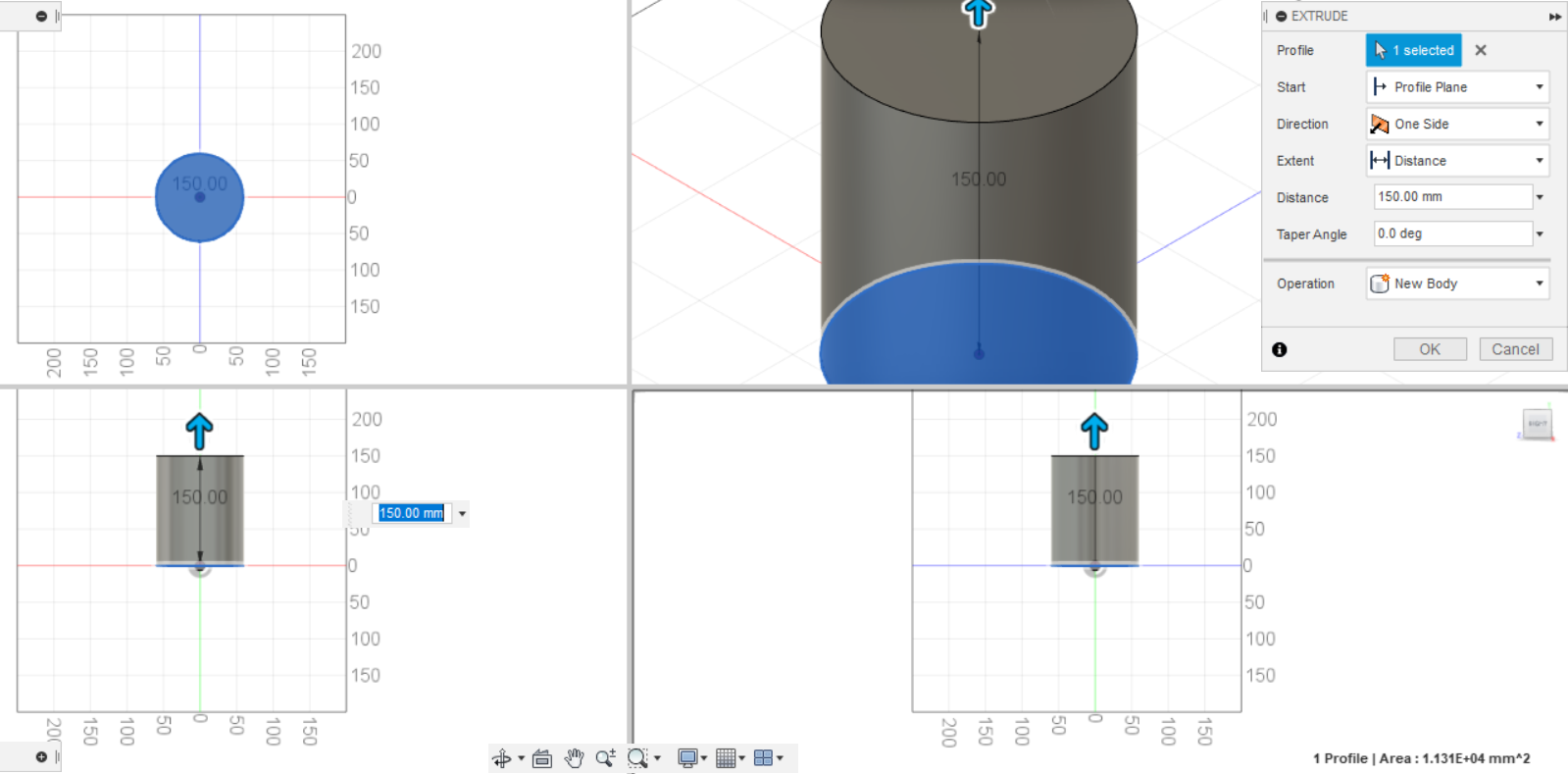

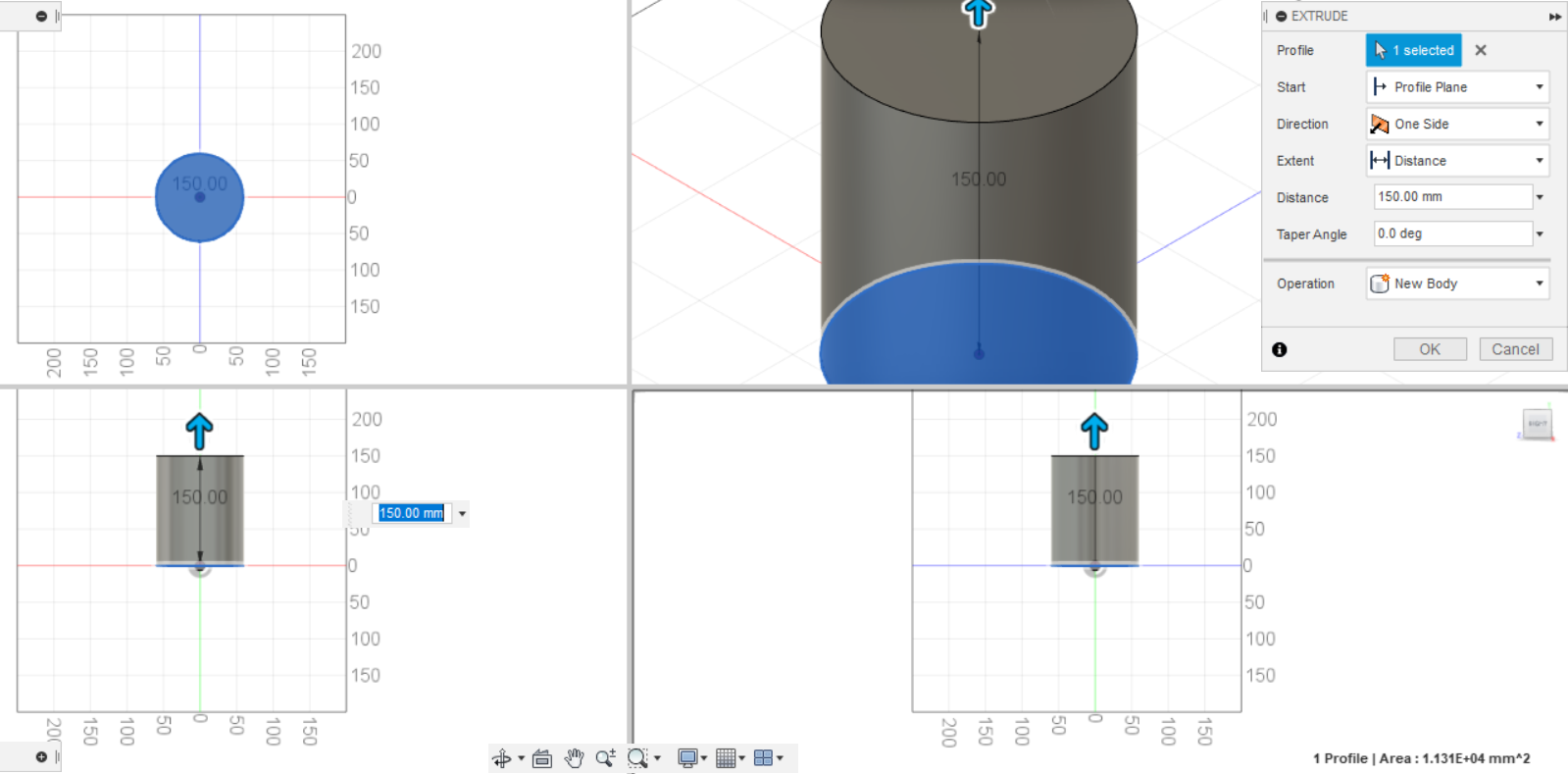

After creating new design under file, we will proceed with sketch. After creating new sketch in 2D.

we will proceed to convert in into 3D by using EXTRUDE, REVOLVE and other commands.

Here are the steps involved

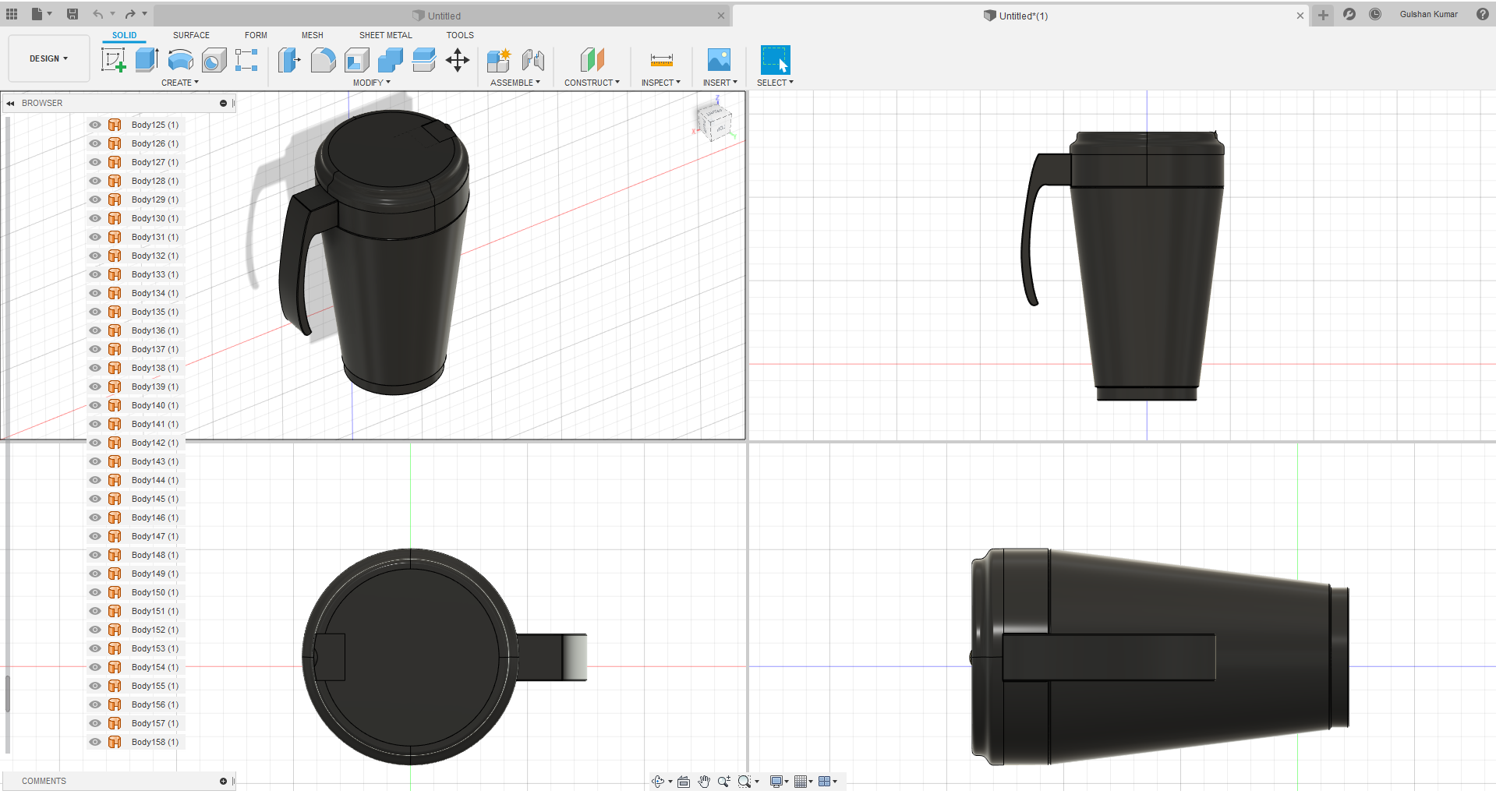

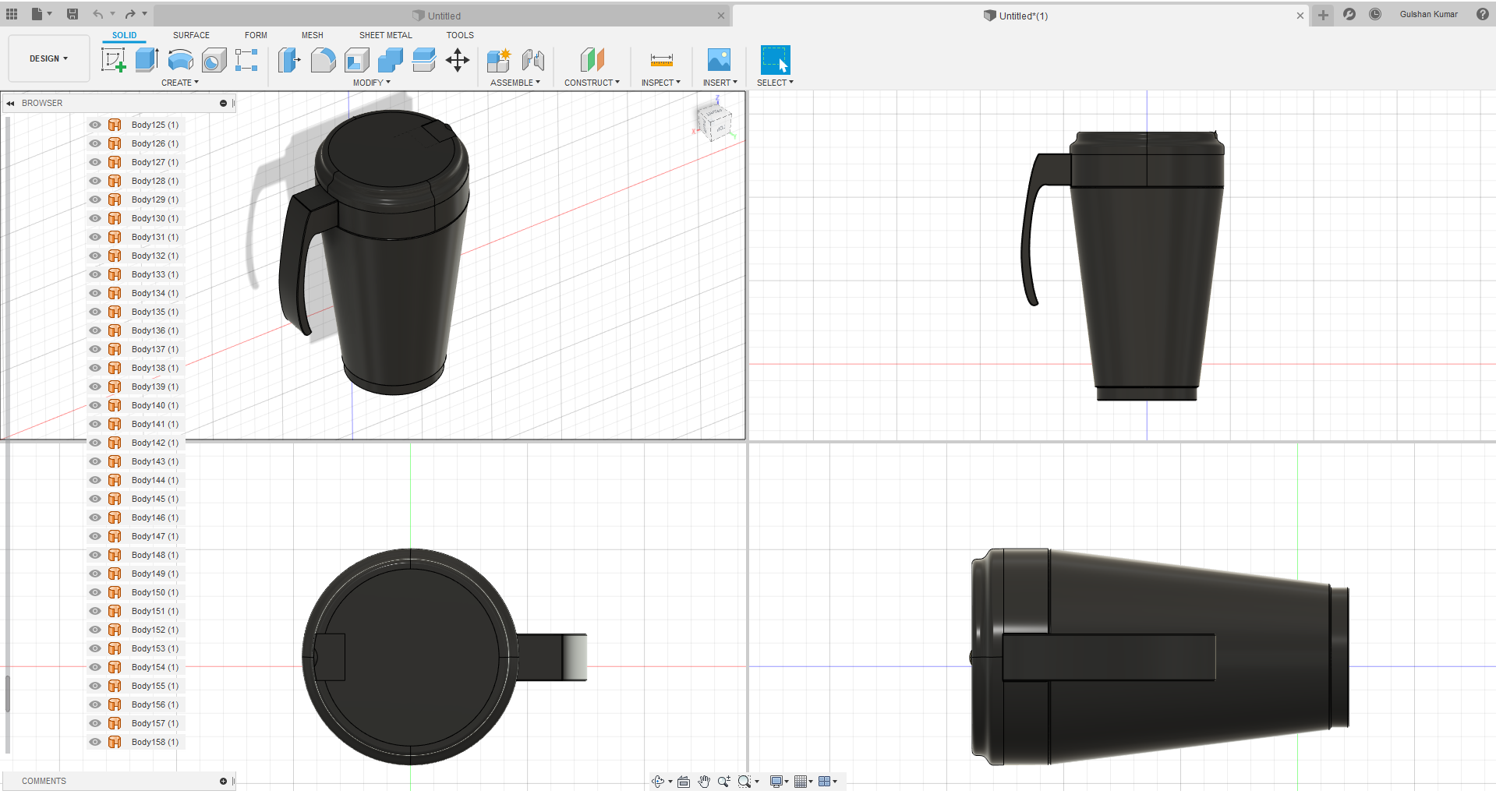

As my coffee mug is madeup of 3 different parts, so i started with base after completing base part i made the handle and final cover. Each part are made seperately and later added using assembly command.

Here you can see view of coffee mug in different perspective.

Here i am including a short video of making a representative 3D model of an old laltern, i have forgotten to enable mic.