Gulshan Kumar

Health and Safety Practice at Makerspace

Accidents at workshop may happen because of improper training of operator,faulty machinery, improper visibility,failure of safety tools, neglecting other co-worker during work etc. below i am listing some of my finding that we should take care while working in makerspace.

Hand and Power tool.

Hand tools requires manual labor to use. Power tools have a power source that allows them to operate automatically and without human intervention. That power source may be a battery, air compressor or electricity. Power tools also have motors and other mechanisms that allow them to run more efficiently and more powerfully than their manual counterparts. Manual tools have fewer moving parts, and their designs are simple in nature. Hand tools have few moving parts, so they tend to last longer than their powered counterparts.Hand tools also give users more control over the tool’s movement, which is ideal for wood carving and tasks that require finely detailed work. The most obvious drawback to using manual tools is that they aren’t as powerful as their powered counterparts. Power tools are usually more precise because they move quickly, and some have guides to make cutting more precise. More power also means that jobs get done far more quickly than they would with a manual tool.

I will show some hand and powertools that i have used in makerspace below.

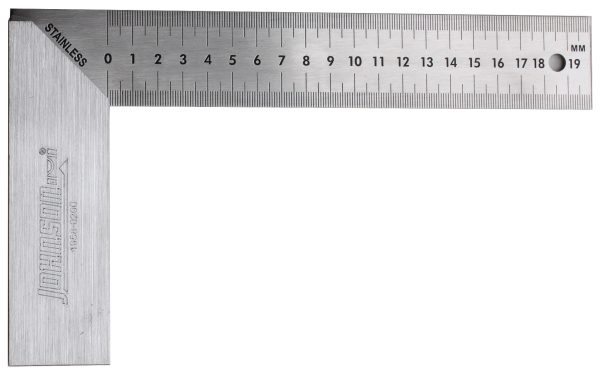

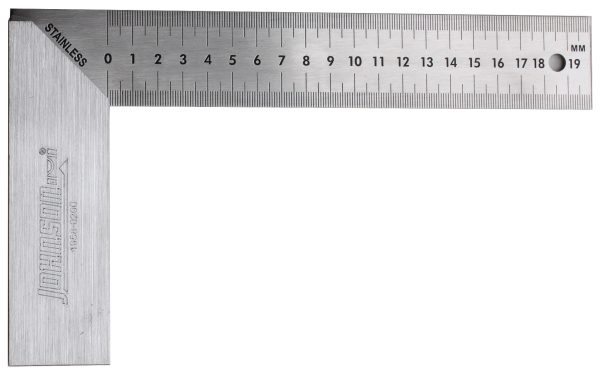

A try square is used to mark or measure in wood and metal.Try squares generally consist of two parts. The ‘blade’ is the longer portion, usually made of metal. The ‘handle’ (or ‘stock’) is usually made of wood, plastic or metal.

C-clamps are used to apply pressure between two plates, holding job at a dezired position. During drilling operation the job needed to be fixed so we use clamp to fix job with bed. During welding of several components again we use clamps to fix the contact.

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

Use to hold small objects tight while grinding, drilling, filing, hammering, sanding, shaping, etc. Jaws have vertical and horizontal V grooves for holding round objects. Use a hand vise and save your fingers. Hand vise has a handle attached to a set of jaws which can clamp down on various items.

Allen key, is a simple tool used to drive bolts and screws with .... Damage to the fastener or the tool can result from using a hex wrench that is too small for the socket.

Again it's like spanner used to created to generate mechanical advantage, but for space which are narrow where normal spanner cannot reach.

A hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called bow saw. Most hacksaws are hand saws with a C-shaped frame that holds a blade under tension.

Inside IIT DELHI makerspace we have a Makita 2012NB 12-Inch Planer. It can plane wooden surface with thickness upto 12-inch. prefferably wood but you can also plane M.D.F. While working with M.D.F requires mask because it will create lot of dust. first we are supposed to set the machine so put your piece inside planer and reduce height till it touches the piece afterit touches blades of planer start the planar machine and with each pass reduce the height of blade. continuous monitoring of thickness and surface finish is required so that we can ensure desired thickness.