Selection of Material

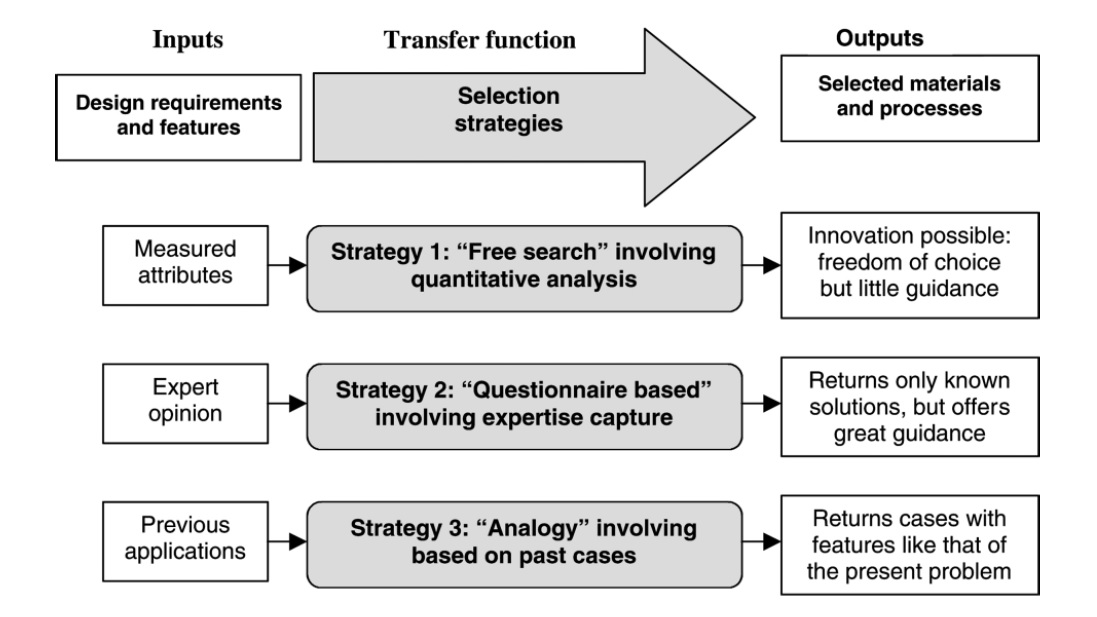

Selection Strategies

"Selection strategy act as a transfer function, converting design requirements into a listing of selected material and processes, with background information about each." Ref. M.F. Ashby et al. Materials and Design 25 (2004)

Assignment Requirement

Selection of material for the course project prototype using Cambridge Engineering Selector Software and document the process

IOT Based Health Monitoring & Gaurded WheelChair

In Course project, an IOT based wheelchair has been attempted. And for the wheel chair, Material Selection CES software is used in a Structured way.

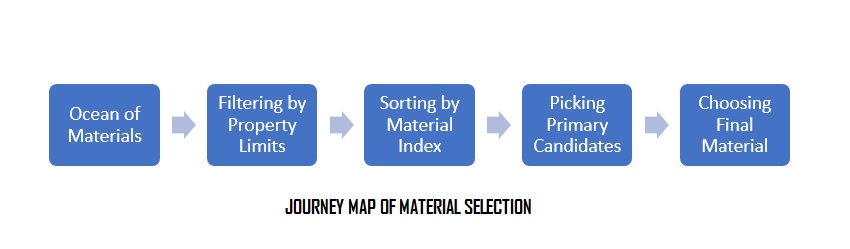

Progression of Material Selection

There are several materials available in Engineering world. Design demands mostly high strength, high resistance to corrossion, low density, low cost, easy availability and flexible manufacturability.

Material Selection for Chasis/Frame

Wheel Chair has multiple component and to address this assignment, selection approach adopted for Chasis/Frame of Wheel Chair is presented.

Stage 1: STRENGTH OF MATERIAL vs DENSITY

Criteria for Stage 1: Material should be stronger enough and light weight. Minimum value of strength of 270 MPa executed for structural design and Density to 7750 kg/m3, so as lesser than steels weight.Point to note that, here strength referring to Maximum tensile strength. As strength is different for different materials, like concrete its crushing strength, elastomers it’s tearing strength, etc. care should be taken appropriately in choosing material.

Stage 2: YOUNG’s MODULUS vs DENSITY

Criteria for Stage 2: Young’s Modulus determines the stiffness or sag ability of Material of construction. Out of shortlisted materials ascending order of materials in accordance with higher rankings are sorted.

Stage 3: FRACTURE TOUGHNESS vs DENSITY

Criteria for Stage 3: Fracture Toughness determines the resistance of Crack propagation once crack has been initiated in the structure. Lower the value brittle is the material, with little load or damage initiation the metal will shatter immediately. On the same front, with higher value of Fracture Toughness, material will deform more & more before tearing. Above 20 MPa m1/2 is the range of Engineering Materials and hence the minimum value for conventional design is kept as 20 MPa m1/2 . Almost all materials shortlisted satisfies this criteria as well.

Stage 4: STRENGTH OF MATERIAL vs COST INR

Criteria for Stage 4: Cheaper material is always preferred in the industry and cheaper material with higher strength is added advantage. Based on the priority criteria we have the shortlisted remains almost same.

Shortlisted Materials: Carbon Fibre Reinforced Polymer; Titanium Alloys;Glass Fibre Reinforced Polymer;Aluminium Alloys

Out of above lists, aluminium alloys are easily available and lower cost compared to other making process.

Stage 5: STRENGTH OF MATERIAL vs MAXIMUM SURFACE TEMPERATURE

Criteria for Stage 5: For wheel chair frame, the temperature range that will be exposed is never more than 200 degree Celsius. From the shortlisted materials, limiting the maximum temperature less than 200 degree Celsius and since it has battery will be used in the design, the proper thermal isolation should be taken care while making enclosure for electronic components. And making them water proof is also very eminent. Design of frame is made in such a way that temperature at frame should not reach above 50 degree Celsius. Aluminium alloys fits to this category as well.

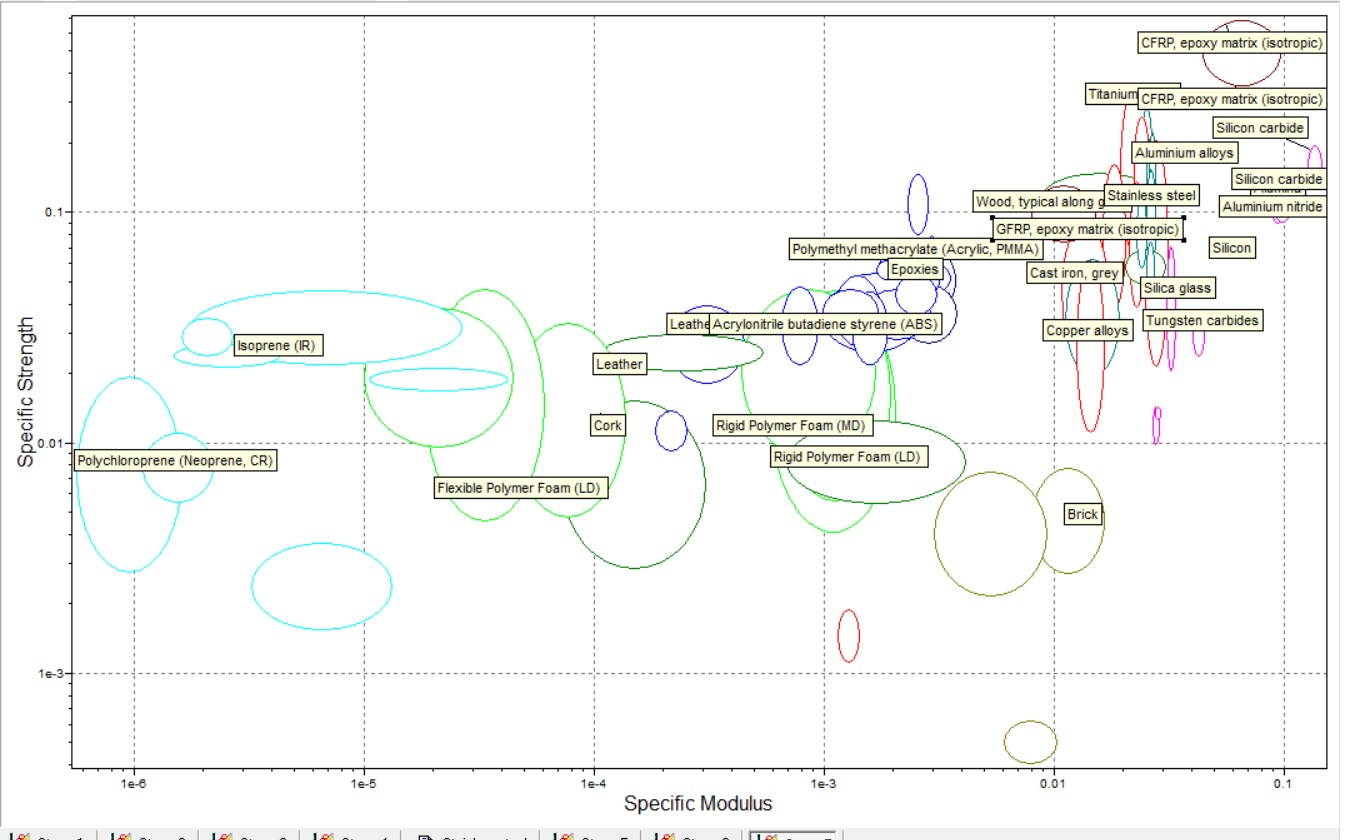

Stage 6: SPECIFIC MODULOUS STIFFNESS vs SPECIFIC STRENGTH OF MATERIAL

Criteria for Stage 6: The ratio of Strength of the Material to its density is the defined as specific strength of the material. This formulation is done by using advanced feature of CES tool. Similarly, the ratio of Young’s modulus to it’s respective density is called as Specific modulus of the material. Aluminium shares the capabilities similar to stainless steel. Less weight with more strength is most preferred. As so, aluminium alloys fits best in the lot.

From the slots of Aluminium alloys, Aluminium 6000 Series is selected as they used in automobile industry which will be optimum for designing Wheel chair frame.

Based on the above stages of selection criteria, Aluminium 6000 series has been selected for the construction of wheel chair frame. In-future, with appropriate market survey apt series of material will be shortlisted.

The Specific Modulus vs The Specific Strength