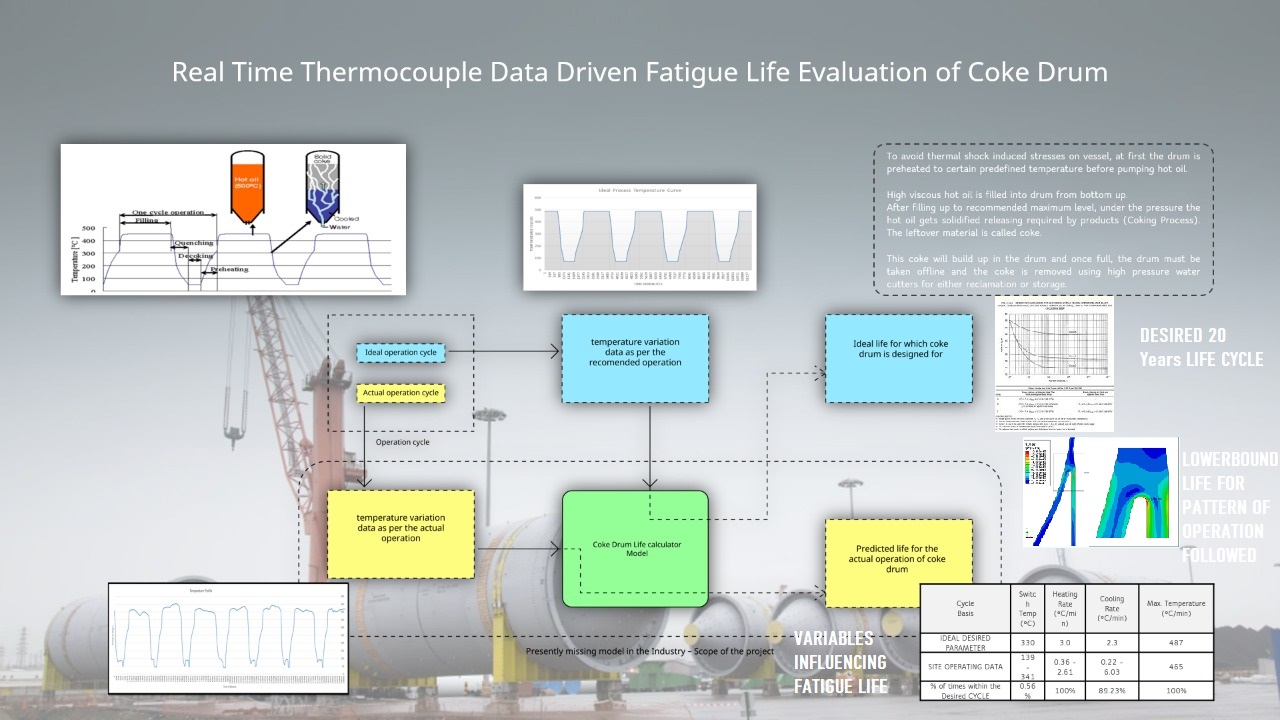

COKEDRUM FATIGUE LIFE EVALUATION

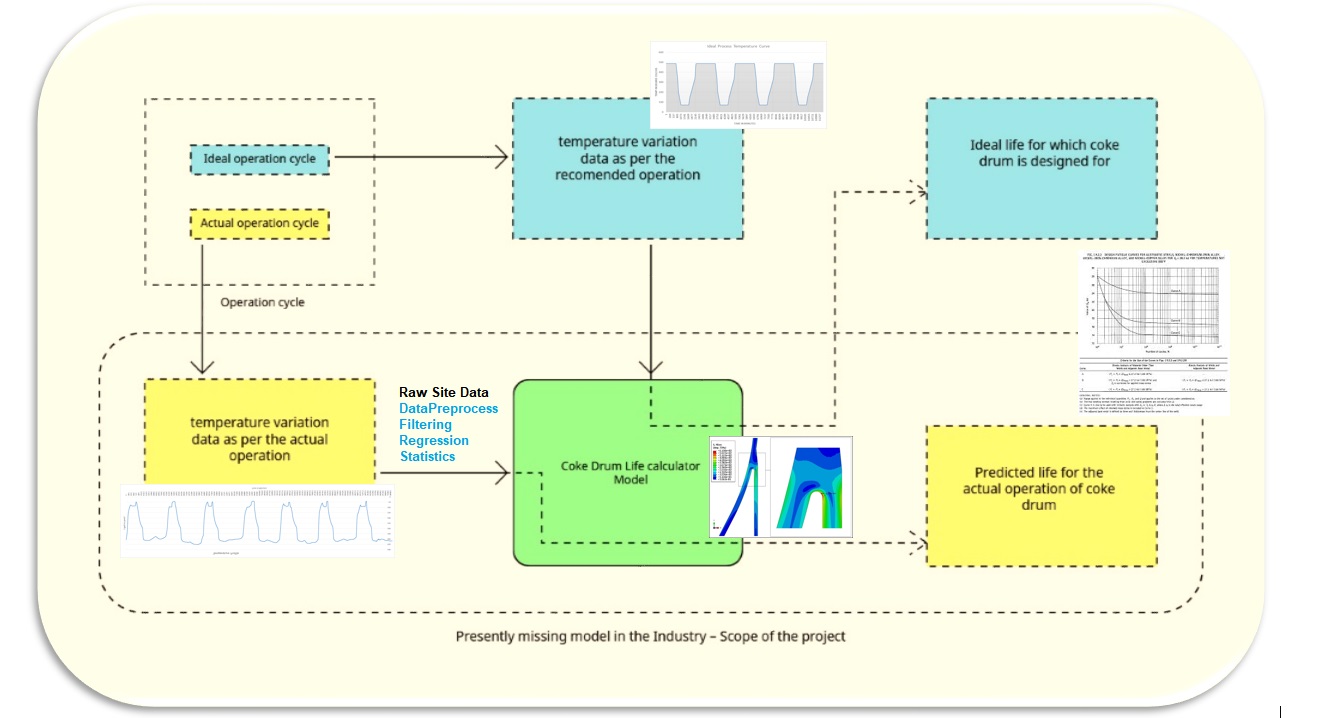

Project Schema

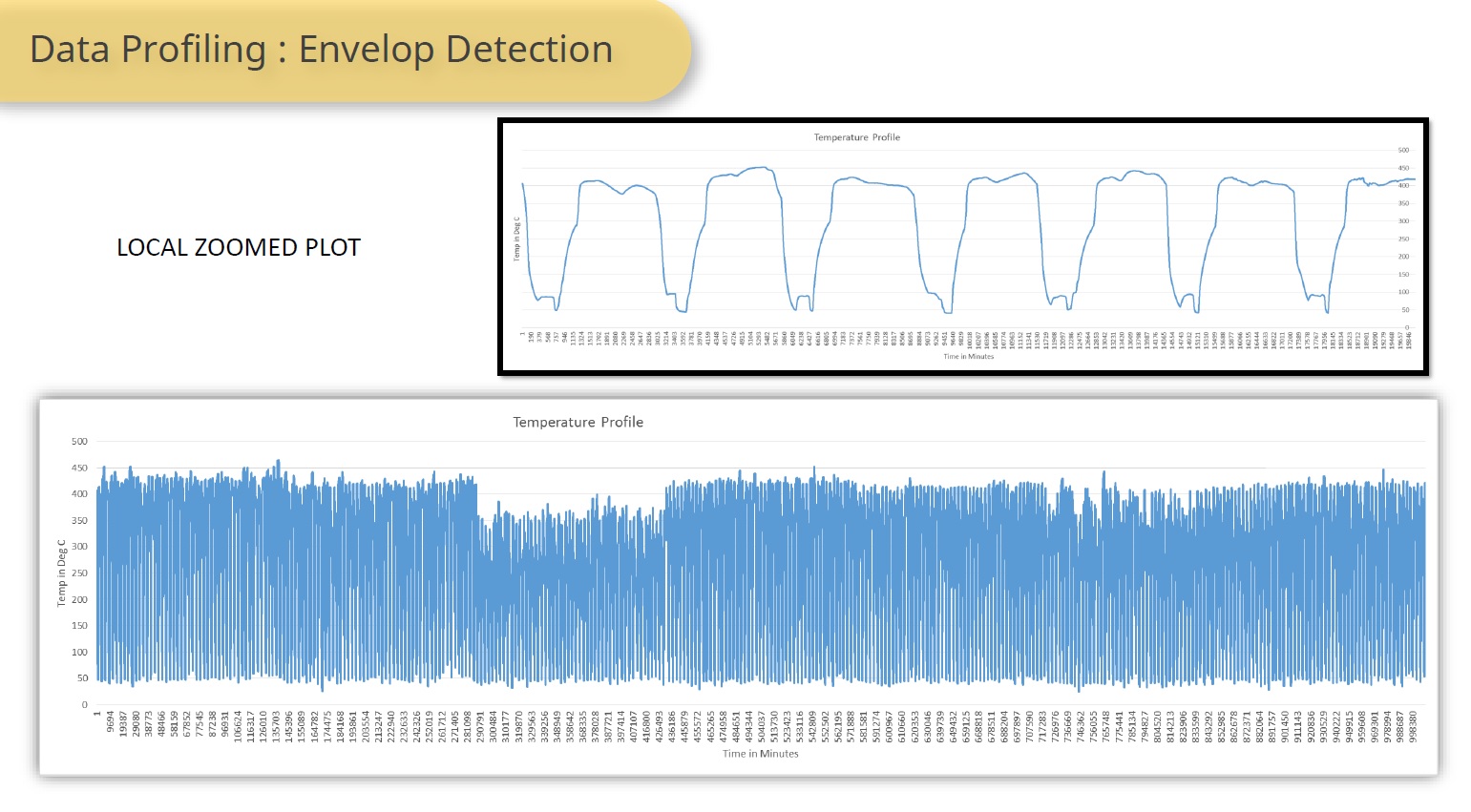

INPUT PROCESSED DATA

Coke drums, are thin-walled pressure vessels that experience severe thermal cycling in normal operation, which consists of heating, filling and rapidly cooling the drum in a short period of time. After some years of operation cracks occur in the coke drum, especially at high stress concentration areas such as the skirt to bottom head attachment, as a result of thermo-mechanical loads experienced during each operating cycle. The attachment is subjected to large variations on the strain field during the entire cycle. In case of unplanned shutting down of coke drum operation in refinery incurs major loss of upto 30-40% of capital, which is never accepted. From the actual data based investigation of coke drum fatigue life,the appropriate & in-line prediction of crack initiation shall be estimated. Study also helps in investigating the performances of each stages of coke drum process, which indirectly leads to inspection of efficiency of ancillary equipments(heat exchanger, columns, pumps etc..) connected to coke drum.

PROJECT ON ONE SLIDE

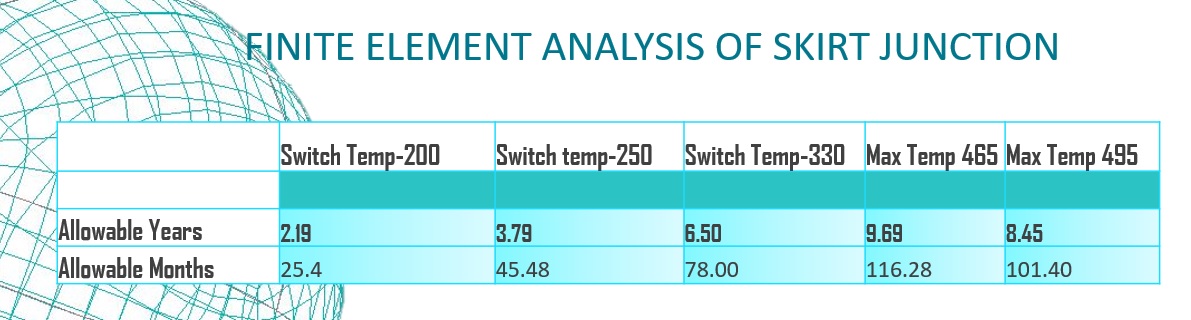

CRITICAL SWITCH TEMPERATURE

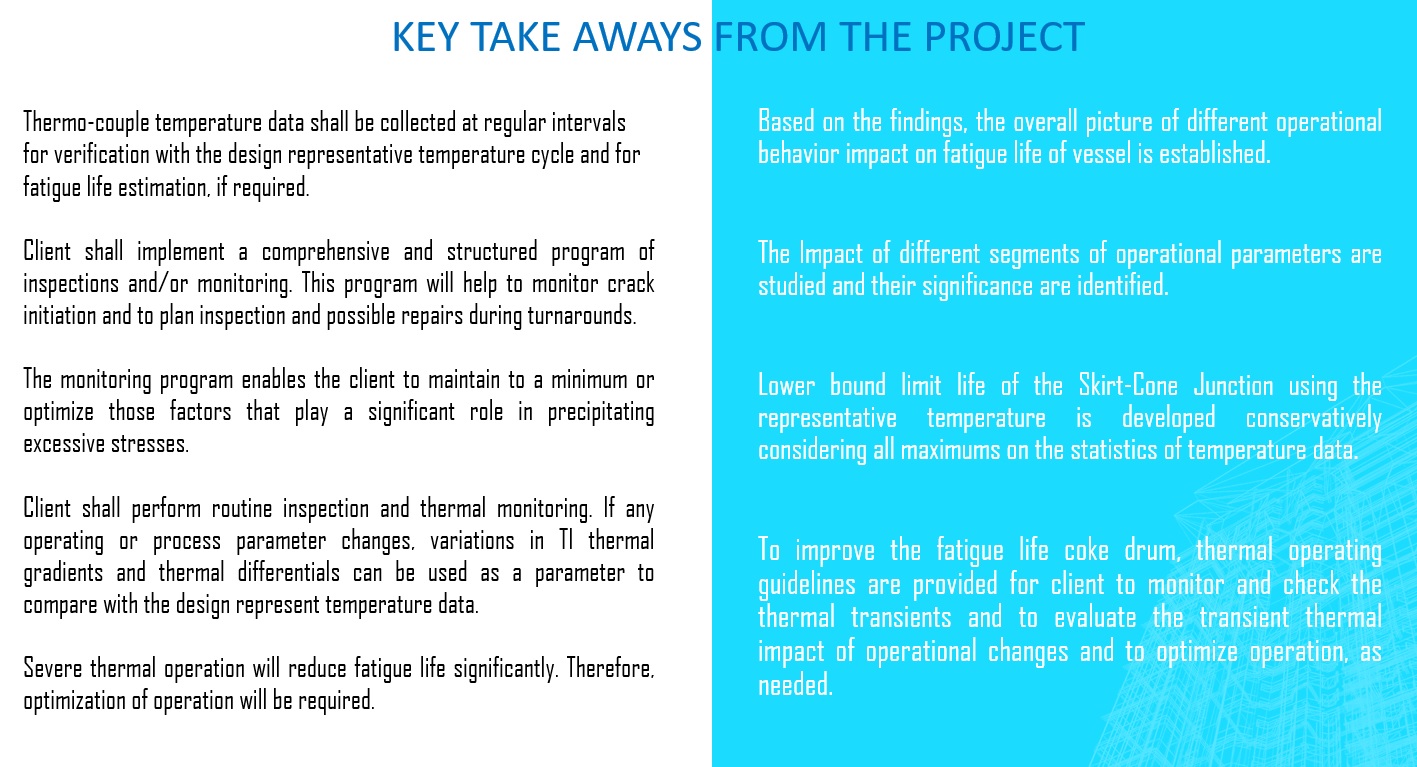

PROJECT KEY TAKEAWAY