Facilities

WITec Alpha 300R Deep UV Raman Microscopy (266nm)

Anton Paar Nano-Indentation System

Ultra nano indentation module.

AFM in contact mode.

Micro indentation and Micro Scratch module.

Nano Tribometer in rotating mode.

Video microscope -5X, 10X, 20X, 50X object.

Contact Angle measurement Setup

Low Temperature GLAD setup

E-beam GLAD Setup

CVD System

Nanoscale Research Facility (NRF)

-

Key features of 300R Deep UV Raman Microscopy

- 266nm CW Solid State Laser from CryLas.

- 3D Raman Imaging with depth profile .

- Fast Raman Imaging with motorized scanning stages.

- WITec Software suite.

- Absence of Background fluorescence in the Raman spectral range.

- Biological and organic materials absorb strongly in the deep UV.

Anton Paar Nano-Indentation System

Contact Angle measurement Setup

- KRUSS Drop Shape Analyzer – DSA25, is an easy-to-use, reliable instrument for measuring contact angle.

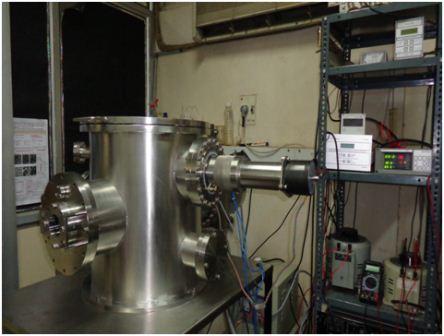

Low Temperature GLAD setup

- Volume of vacuum chamber is about 23 L.

- Rotary (DS102, Varian Inc.) and turbo molecular pump (250 L/Sec, 301 Navigator, Varian Inc.) are used to evacuate the chamber.

- The pressure of better than 2´10-6 Torr can be attained.

- Thermal evaporation method is used for thin film growth.

- Thermal deposition boat connected to 400 Amp power supply is placed at the bottom plate of chamber.

- Substrates can be placed above the deposition source at various oblique angles (α) ranging from 65° to 87°. Source to substrate distance is 24 cm.

- Substrates temperature can be controlled in the range from 350 K to 100 K with the accuracy of ±2 K.

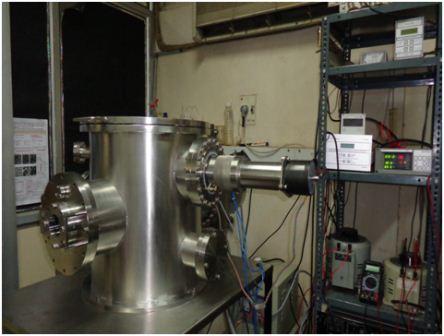

E-beam GLAD Setup

- Triscroll (300, 300 L/min. Varian Inc.) and turbo molecular pump (V 1001 Navigator, 800 L/Sec, Varian Inc.) are used to evacuate the chamber.

- The pressure of better than 5 x 10^-7 Torr can be attained.

- Thermal evaporation and e- beam evaporation method is used for thin film growth.

- Thermal deposition boat connected to 400 Amp power supply is placed at the bottom plate of chamber.

- Substrates can be placed above the deposition source at various oblique angles (α) ranging from 0ᵒ to 90ᵒ.

CVD System

Chemical Vapour Deposition system used for growth of Indium oxide nanostructures. Hydrogen doped nanostructures can also synthesized. Details of parts attached in system are below:

- Single zone tube furnace heated up to 1100 ᵒC .

- Mass flow controller for Ar gas which can control flow rate from 0 to 500sccm.

- A reservoir at upstream direction of gas flow, for mixing particular ambient like water, ethanol etc. vapours with Ar gas during growth. Heating mantle is used for adjusting temperature of ambient.

CVD system for growth of different metal oxides . Detailed description is below:

- Two zone split furnace . One zone heated up to 1350ᵒ and other with 500 ᵒ .

- Mass flow controller which can be used for 31 gases we can control flow rate from 0 to 500sccm

- Assembly for using ambient during growth.

- A cryostat circulating bath with temp. range of -10 ℃ to 40 ℃.

Nanoscale Research Facility (NRF)

Renishaw Raman System

- 785nm diode laser system.

- Maximum counts upto 80,000.

- 5X, 20X, 50X, 100X microscope objective.

- Optimum focus is maintained in real time during data collection and white light video viewing.

- Analyse samples with uneven, curved or rough surfaces.

Horiba LabRAM HR Evolution 800

- Microscope objective 10X, 50X, 100X

- Three laser 325nm He-Cd., 514nm Ar ion, 785nm He-Ne

- Ultra cooled CCD detctor.

- Mapping facility.

- Photoluminescence(PL).

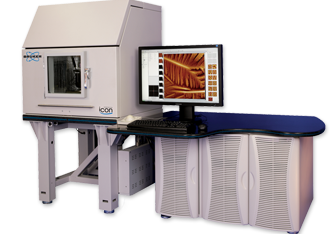

The Dimension Icon Atomic Force Microscope

The Dimension Icon Atomic Force Microscope brings new levels of performance, functionality, and AFM accessibility to nanoscale researchers in science and industry.

The Icon is also equipped with proprietary ScanAsyst automatic image optimization technology, which enables easier, faster, and more consistent results, regardless of user skill level. The Icon’s uncommon ease of use, ultimate performance, exceptional productivity, and superior versatility make it an ideal choice for practically every AFM application.

Electron Beam Evaporation System

- E-beam Evaporator System with Liquid Nitrogen Cooled Substrate Holder.