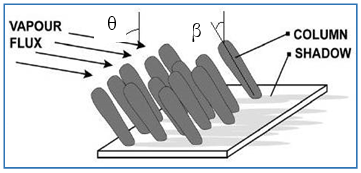

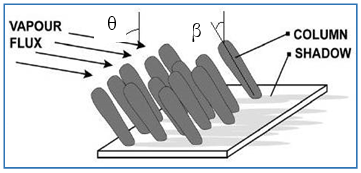

Glancing Angle Deposition (GLAD) is a physical vapor deposition process where the deposition flux is incident onto a substrate making a large angle (θ) with respect to the surface normal and the substrate is rotating in its azimuth plane. The schematic of GLAD is shown in Fig. 1.

GLAD produces columnar structures through the effect of shadowing during film growth (schematic shown in Fig. 2), and the shape of these structures can be changed by rotating the substrate at different speeds.

Relation between column tilt angle (β) and vapor incident angle (θ) is given by:

tangent rule: tan β = ½ tan θ (for small θ)

cosine rule: β = θ – arc(1-cos θ)/2

Morphology of film in GLAD depends on following growth parameters:

• Glancing angle

• Rotation speed of substrate

• Deposition rate

• Atomic surface diffusion ( which is decided by material and surface temperature ).

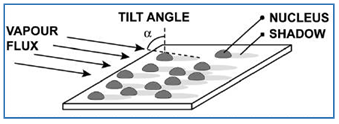

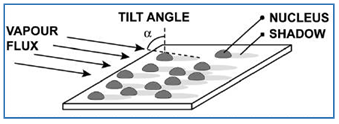

During deposition in GLAD initial nucleation centers grow randomly over the substrate but by creating artificial nucleation center over substrate we can tune the distribution and broadening of these structures.

This technique has many advantages in terms of controlling the growth of nanostructured thin films.

It can form nano-column array naturally. The porosity of the film can be controlled by simply changing the incident angle.

The shape and in-plane alignment of columns can be easily modified. It has the advantage of self-alignment due to the shadowing effect. It can also generate three-dimensional nanostructures.

These advantages make GLAD technique very promising for nanostructure fabrications. Depending on the morphology of these GLAD structures different surface and morphology dependent properties of materials can be changed and these structures find potential applications in many fields such as biosensing, optical coatings, pressure and humidity sensors, LCD displays, and in energy related fields.