Layer Transfer of 2D Materials Using Quasi-Dry

Method

The quality of a synthesized film depends on

various factors, including the choice of substrate for film deposition, what

are the required precursors for growth, growth pressure and temperature, and so

on. Most TMDCs are typically synthesized at temperatures above 500 °C, making

it impractical to deposit on temperature-sensitive substrates. There are

several layer transfer processes to overcome the temperature dependent issues such

as the wet-etching method, water-assisted transfer method, double support

layer-based transfer method, and so on that have been studied and optimized for

two-dimensional (2D) materials in our lab group. Presently, the wet etching

transfer is extensively employed for the transfer of MoS2. The wet

etching method involves applying a layer of polymethylmethacrylate (PMMA) onto

the MoS2 material through spin coating. The PMMA/MoS2

stack is then separated from the substrate using chemical etching, typically

employing hydrogen fluoride (HF) or other strong etchants. However, this

chemical etching process can harm the MoS2 film and degrade its

quality, which is undesirable for the heterostructure formation. Therefore,

there is a strong demand for a highly efficient, repeatable transfer approach

that avoids damage and ensures the preservation of film integrity.

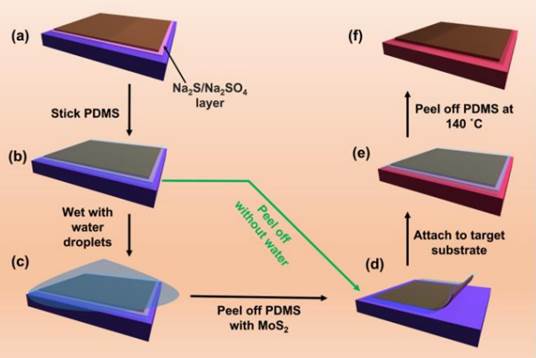

In our lab, we developed a novel transfer

process named the quasi-dry layer transfer method, free from PMMA residues and

chemical etchants. The schematic illustration for MoS2 layer

transfer by this process is shown in Figure 1. Since this layer transfer method

utilizes only PDMS and water, it can be referred to as the quasi-dry layer

transfer method. Furthermore, the quasi-dry layer transfer process has emerged

as a highly versatile technique for creating 2D/2D (MoS2/WS2

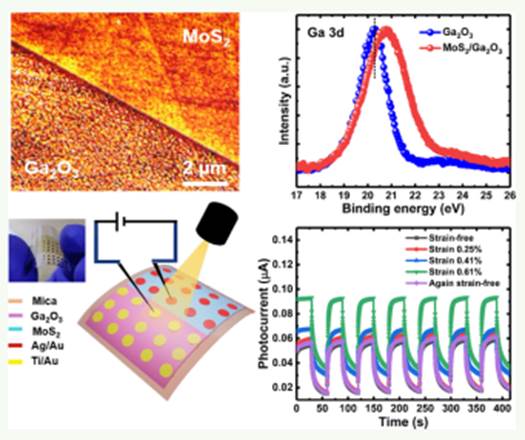

and vice versa) and 2D/3D (MoS2/β-Ga2O3) van der Waals (vdW) heterostructures as shown in Figure 2. We also

fabricated MoS2/mica and MoS2/β-Ga2O3/mica

flexible photodetectors and studied their performance with bending/tensile

strain and temperature. The responsivity and detectivity of the MoS2/mica

flexible photodetector were found to be 1.10 mA/W and 3.86 × 1010 Jones,

respectively. The PDCR, responsivity, and detectivity of the MoS2/β-Ga2O3/mica

flexible photodetector were calculated to be 103, 7.21

mA/W, and 2.4 × 1011 Jones, respectively. The photocurrent and responsivity

were increased by 155% and 136% under 0.61% tensile strain.

![]()

Figure 1.

Schematic of MoS2 layer transfer by quasi-dry layer transfer process

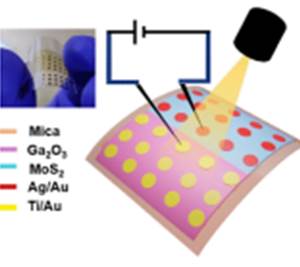

Figure 2. (a) AFM image of

the MoS2/β-Ga2O3

heterostructure, (b) XPS spectra of the Ga 3d core level for pristine β-Ga2O3

and MoS2/β-Ga2O3,

(c) Schematic illustration of the MoS2/β-Ga2O3

flexible photodiode, (d) Time-dependent photoresponse

of the device under different bending states (strain states)