Advancements in Material Synthesis via Chemical

Vapor Deposition

The

Chemical Vapor Deposition (CVD) technique plays a pivotal role in the growth of

materials, offering unparalleled control and precision in material synthesis.

CVD allows for the creation of large-area, high-quality materials with

controllable properties, making it indispensable for a wide range of

applications, from cutting-edge electronics and optoelectronics to energy

storage and sensing. Its scalability, versatility in precursor materials, and

ability to fine-tune growth parameters empower researchers and industries to

tailor 2D materials to specific needs. As a cornerstone in the 2D material

synthesis toolkit, CVD contributes not only to the advancement of technology

but also to our understanding of fundamental material science, making it a

crucial technique for unlocking the potential of 2D materials in the modern

world.

Two-dimensional

(2D) materials, such as graphene, transition metal dichalcogenides (TMDs), and

black phosphorus, have emerged as remarkable materials with a wide range of

applications in electronics, optics, energy storage, and more, owing to their

exceptional properties. The synthesis of these materials using Chemical Vapor

Deposition (CVD) techniques is of paramount importance because it enables

precise control over material properties, scalability for industrial

applications, and the creation of large-area, high-quality films.

The

purpose of this report is to highlight the expertise of our laboratory in the

synthesis of materials using CVD techniques. We will describe our experience

and proficiency in this field, demonstrating our ability to harness CVD methods

for the controlled growth of 2D materials. This report serves as a testament to

our capability to produce high-quality 2D materials, which have a promising

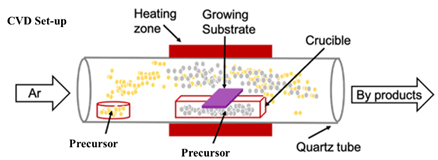

future in various technological and scientific applications. In our lab we have

single-zone APCVD system (MTI Corporation, OTF-1200X-S50-2F) and its schematic

is as shown in Figure 1.

Figure 1 Schematic of CVD set-up

The

early developments in CVD synthesis were done on β -gallium oxide in our

lab. The research conducted by Sudheer Kumar, Vipin Kumar, Trilok Singh, A. Hähnel, and Rajendra Singh

investigates the impact of deposition time on the structural and optical

properties of β-Ga2O3 nanowires synthesized via the

Chemical Vapor Deposition (CVD) technique. While specific details of the

research are not provided, the study likely explores the systematic variation

of deposition times to understand how they affect the crystal structure,

morphology, and optical characteristics of the β-Ga2O3

nanowires. This research aims to provide insights into optimizing the growth

process for tailored properties, which is essential for potential applications

in optoelectronics, sensing, and related fields. By gaining a deeper

understanding of how deposition time influences structural and optical

properties, this study contributes to the knowledge required for the precise

engineering of β-Ga2O3 nanowires with desired

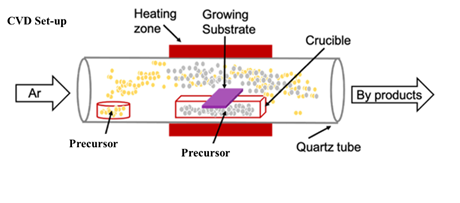

characteristics [1]. Some of their results are listed in Figure 2.

Figure 2 a

TEM image showing the general morphology of b-TEM image showing the general

morphology of β-Ga2O3 nanowires grown using Au

catalyst at 900°C for 4 h, (b–c) TEM images of β-Ga2O3

nanowires at low and higher magnifications, (d) HRTEM image of a single β -Ga2O3

nanowire. The d-spacings between the fringes are marked in the image which is

overlaid with the model of the β-Ga2O3 structure, (e)

Fast Fourier-Transform (FFT) of the single β -Ga2O3

nanowire in (d) specifying the orientation of the wire axis by the streak

In an extended study by Sudheer et

al. on beta gallium oxide (β -Ga2O3)

nanowires (NWs), the growth of these NWs using the Chemical Vapor Deposition

(CVD) technique on different substrates was investigated in our lab. The study

involved the growth of β -Ga2O3

NWs on three different substrates: silicon (Si), sapphire, and GaN/sapphire. Field emission scanning electron microscopy

(FESEM) results showed that the NWs grown on GaN/sapphire

exhibited superior alignment compared to those on the other substrates. The diameter

of the β -Ga2O3

NWs ranged from 150 to 400 nanometers, and they

reached lengths of several tens of micrometers. This

indicates the ability to control the size and length of the NWs during the CVD

growth process. X-ray diffraction (XRD) and high-resolution transmission

electron microscopy (HRTEM) confirmed that the NWs possessed a single

crystalline monoclinic structure. This demonstrates the high-quality

crystalline nature of the NWs. Raman spectroscopy analysis revealed that the

samples had similar Raman spectra with two active modes - mid and high

frequency. Notably, a low-frequency mode was absent in the results. Cathodoluminescence

(CL) spectra of β -Ga2O3

NWs on different substrates showed a strong broad UV-blue emission band and a

weaker red emission band across all the samples. This suggests that the optical

properties of the NWs were consistent, regardless of the substrate used. In

summary, the study found that the morphological and structural properties of β -Ga2O3 NWs

grown on different substrates exhibited some variations, with superior

alignment observed on GaN/sapphire. However, their

optical properties remained quite similar, as indicated by the consistent

UV-blue and weak red emission bands in the CL spectra [2]. These findings

provide valuable insights into the controlled synthesis of β -Ga2O3 NWs for

various applications. The successful growth of gallium oxide was a significant

achievement in our laboratory, demonstrating our proficiency in utilizing the

Chemical Vapor Deposition (CVD) technique for advanced material synthesis.

The

study conducted by Aditya Singh, Madan Sharma and Rajendra Singh focuses on the

NaCl-assisted Chemical Vapor Deposition (CVD) growth of trilayer

molybdenum disulfide (MoS2) and investigates

the role of the concentration boundary layer in 2D material synthesis. They utilized

a two-zone horizontal tube furnace for the CVD process. The precursor for

molybdenum was Mo(CO)6, and sulfur was

introduced in the form of H2S gas. The innovation in this study was

the introduction of sodium chloride (NaCl) as a transport agent. Fine NaCl

powder was employed, which was essential for enhancing the growth of trilayer MoS2. The growth process took place on

SiO2/Si substrates. Various growth parameters, such as temperature

and duration, were systematically varied to understand their effects on MoS2

growth. NaCl acted as a catalyst, promoting the formation of trilayer MoS2 while inhibiting the growth of

monolayer or bilayer MoS2. This selective growth is of paramount

importance as it enables the controlled synthesis of trilayer

MoS2, which is particularly desirable for certain applications,

including optoelectronics. The use of NaCl led to the production of

high-quality trilayer MoS2. The resulting

material exhibited improved properties, making it suitable for advanced device

applications. By adjusting the growth parameters and optimizing the

concentration boundary layer, they successfully achieved the large-area

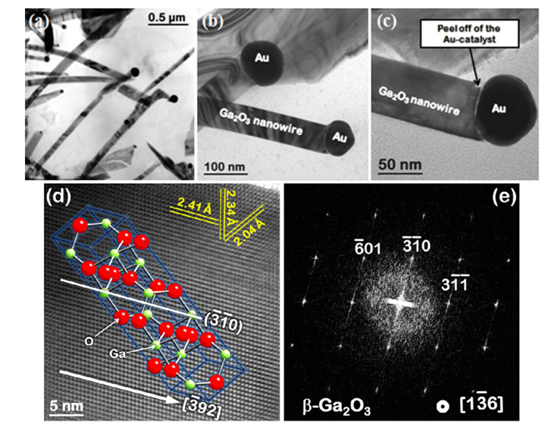

synthesis of trilayer MoS2[3]. XPS, XRD, TEM

and SAED pattern is shown in Figure 3 which reveals the quality of grown 3L MoS2

film.

Figure 3 a) XPS survey spectrum of 3L-MoS2.

Core-level XPS spectrum of (b) molybdenum and (c) sulfur.

(d) XRD of 3L-MoS2 grown over the SiO2/Si substrate. (e)

TEM image of 3L-MoS2 and the marked white triangle shows the region

where the SAED pattern was taken and is depicted in (f).

Notably, Aditya Singh et al., as part

of our research team, have also played a pivotal role in extending our lab's

capabilities and expertise to another frontier: the controlled synthesis of

molybdenum disulfide (MoS2) using CVD. Their work represents a

notable accomplishment, providing valuable insights and strategies for

precisely engineering 2D materials, such as MoS2, which is of great

interest due to its exceptional properties and wide-ranging applications. Aditya

Singh and their team have shown remarkable skill and innovation in developing

techniques for the controlled growth of MoS2 via CVD. This accomplishment is of

utmost importance, as the controlled synthesis of 2D materials is a challenging

and critical aspect of modern materials science. By achieving this, they have

unlocked the potential to customize the properties of MoS2 for

specific applications in electronics, photonics, and more. Their contributions

underscore the laboratory's dedication to advancing the field of materials

science and its commitment to staying at the forefront of cutting-edge

research. The insights and strategies provided by Aditya Singh and the team not

only add to the collective knowledge in the realm of 2D materials but also

position our laboratory as a leader in the controlled synthesis of these

materials, fostering innovation and driving the development of future

technologies. This achievement is a testament to the lab's commitment to

excellence and its contribution to scientific progress. The key findings and

advancements in this research are as follows. The study involves a quantitative

comparison of three different precursors for CVD synthesis of MoS2,

namely molybdenum trioxide (MoO3), ammonium heptamolybdate

(AHM), and tellurium (Te) [4]. This comparison

provides crucial information for selecting the most suitable precursor for MoS2

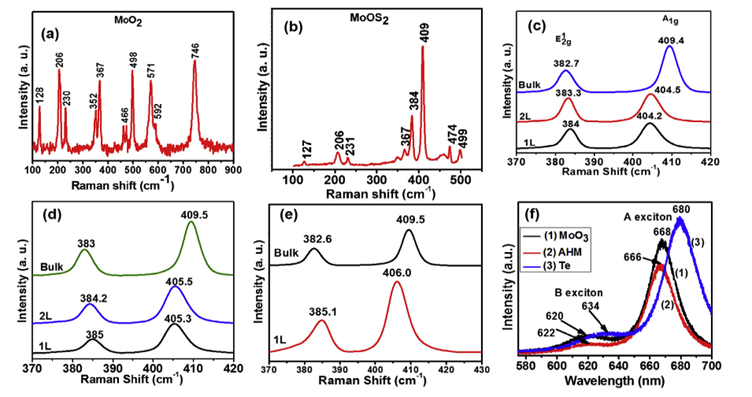

synthesis. Raman spectroscopy as a function of active precursors is shown in

Figure 4.

Figure 4 (a) and (b) Raman spectra of micro

particles of MoO2 and MoOS2, respectively. (c) Raman

spectrum of crystalline 1L, 2L, and bulk MoS2 synthesized using MoO3

precursor (d) and (e) Raman spectra of CVD MoS2 synthesized by AHM

powder and Te-assisted growth, respectively. (f) PL

spectrum of MoS2 triangular MoS2 flakes grown via a

different combination of precursors. PL spectrum (1), (2), and (3) correspond

to MoS2 synthesized by MoO3, AHM and Te

assisted, respectively. In all these three PL spectrums, higher and lower

energy peak corresponds to B exciton and A exciton, respectively.

Further,

the research is carried forward by Pallavi et al., who represent a significant

advancement in the synthesis of large-area monolayer tungsten disulfide (WS2)

using atmospheric-pressure Chemical Vapor Deposition (CVD). This work delves

into the growth mechanism and the influence of various parameters, including

the use of NaCl as a growth promoter, sulphur quantity, temperature, gas flow

rate, and hold time. Through the examination of optical microscope images,

Raman, and photoluminescence spectra at different synthesis parameters, the scholars

provided valuable insights into the WS2 film's growth process. The

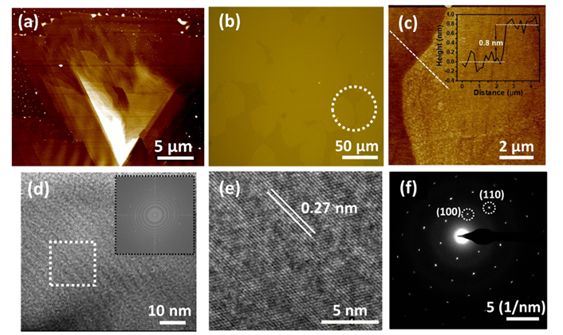

AFM and HRTEM data shown in Figure 5 confirm the successful large-area growth

of monolayered WS2 film is achieved.

Figure 5 (a) AFM image of the region

highlighted in Figure 4a. Triangular stacks indicate island growth. (c) AFM

image of the large-area monolayer WS2 film shown in (b). A line

profile spectrum is taken along the dashed line. (d) Low-resolution HRTEM image

of the freely suspended film on a TEM grid. The inset of the image shows the

FFT pattern, and the hexagonal arrangement of dots represents its six-fold

symmetry. (e) Zoomed-in HRTEM image of the region shown in (d) (f) SAED pattern

of the freely suspended film on a TEM grid

Furthermore,

they successfully fabricated photodetectors with high responsivity and specific

detectivity in both the visible and ultraviolet regions, demonstrating the

material's potential for UV-visible photodetection applications. This work

showcases the significance of controlled synthesis techniques for enabling

large-area production of 2D materials with tailored properties and their

subsequent application in advanced photodetection

technologies [5].

The

prospects of 2D materials synthesized using CVD techniques by our lab hold

great promise for advancing future electronics. By tailoring the properties and

quality of 2D materials, we can contribute to the development of ultra-thin,

high-performance transistors, sensors, and photodetectors, enabling more energy-efficient

and faster electronic devices. This innovation has the potential to

revolutionize the electronics industry and drive the creation of

next-generation technologies.

References

1. Kumar,

S., Kumar, V., Singh, T., Hähnel, A., & Singh, R.

(2014). The effect of deposition time on the structural and optical properties

of β-Ga2O3 nanowires grown using CVD technique.

Journal of nanoparticle research, 16, 1-9.

2. Kumar,

S., Tessarek, C., Christiansen, S., & Singh, R.

(2014). A comparative study of β-Ga2O3 nanowires

grown on different substrates using CVD technique. Journal of alloys and

compounds, 587, 812-818.

3. Singh,

A., Sharma, M., & Singh, R. (2021). NaCl-assisted CVD growth of large-area

high-quality trilayer MoS2 and the role of

the concentration boundary layer. Crystal Growth & Design, 21(9),

4940-4946.

4. Singh,

A., Moun, M., & Singh, R. (2019). Effect of different precursors on CVD

growth of molybdenum disulfide. Journal of Alloys and Compounds, 782, 772-779.

5. Aggarwal, P., Kaushik, S., Bisht, P., Sharma,

M., Singh, A., Mehta, B. R., & Singh, R. (2022). Centimeter-scale

synthesis of monolayer WS2 using single-zone atmospheric-pressure

chemical vapor deposition: a detailed study of parametric dependence, growth

mechanism, and photodetector properties. Crystal Growth & Design, 22(5),

3206-3217.